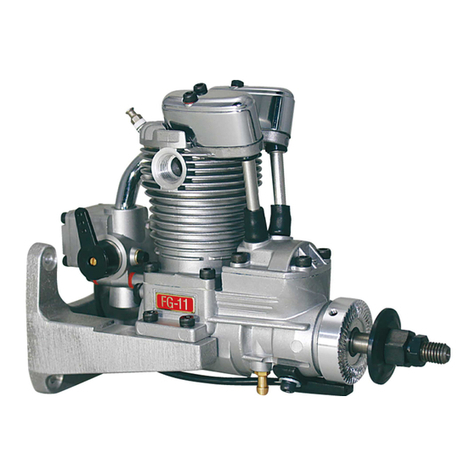

Φ29.0mm 20.4mm 13.5cc

13”x8“~14”x6”

・Filterwithweight[G36-154] ・DurabletubeforGasoline(1m)[G36-155] ・Aluminumspinnernut[50-30]

・Tappetadjustingkit[30-161] ・Digitaltachometer[G17-167]

Bore Body:528g/Muffler:50g/Ignitionsystem:100g/Enginemount:124gStroke Disp.Weight(Approx.)

RPMRange Approx.1,900-9,500rpm Maxonground Approx.8,500-9,000rpm

Propeller SP-1orSP-2Plug

Optionalparts

4-strokeglow60-80classApplications

Batteryforignitionsystem

Specifications

FG-14CInstructionManual

2.Ignition

●Ignitionarrangement-Placethemainunitasfarfromother

electricaldevicesaspossible.

(1)Plugcord(meshedhightensioncord)

Inserttheplugcapoftheplugcorddeeplyintotheplug

attachedtothecylindertomakesureitwillnotcomeoff.

(2)Sensorcord

Connectwiththecordfromthesensorattachedtotheengine.

(3)Batterycord(black/redcord)

Useafullychargedbatterythathasadequatespec.(6-12V,more

than1000mAisrecommended).Betweenthebatteryandmain

unit,makesuretosetaheavydutyswitchwhosecapacityis

higherthan3A.

(4)Tachometercord

Connectthedigitaltachometer(Option).Otherwisetheconnec-

torisnormallyvacant.

※

Standard

accessories

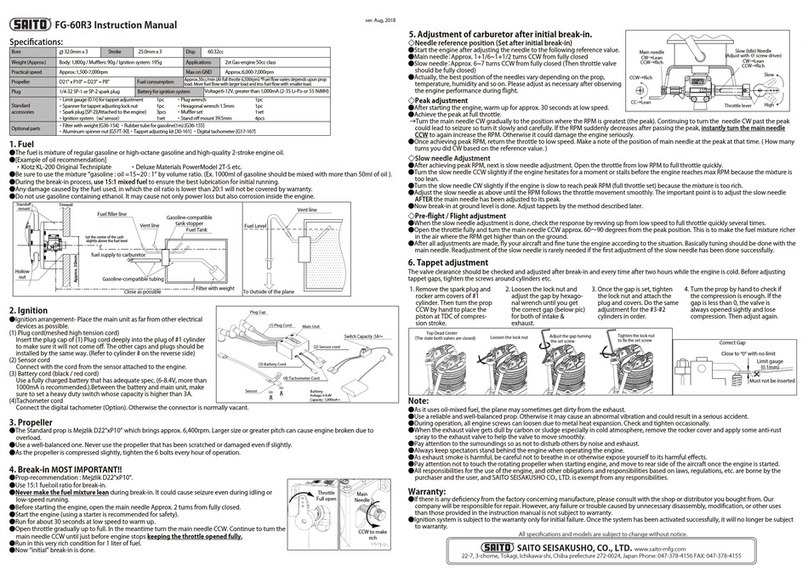

6.Tappetadjustment

ThevalveclearanceshouldbecheckedandadjustedafterBreak-inandeveryafter2hourswhiletheengineiscold.Beforeadjusting

tappetgaps,tightenthescrewsaroundcylinderetc.

1.Removethesparkplugand

rockerarmcoversfromthe

cylinder.Thenturntheprop

CCWbyhandtoplacethe

pistonatTDCofcompression

stroke.

2.Loosenthelocknutand

adjustthegapbyhexagonal

wrenchuntilyougetthe

correctgap(belowpic)for

bothofintake&exhaust.

3.Oncethegapisset,tighten

thelocknutandattachthe

plugandcovers.

4.Turnthepropbyhandto

checkifthecompressionis

enough.Ifthegapislessthan

0,thevalveisalwaysopened

sightlyandlosecompression.

Thenadjustagain.

CorrectGap

Mustnotbeinserted

Closeto“0”withnolimit

Limitgauge

(0.1mm)

Loosenthelocknut

Adjustthegapturning

thesetscrew

TopDeadCenter

(bothvalvesareclosed) Tightenthelocknut

tofixthesetscrew

・Enginemountset 1set ・Limitgauge(0.1t)fortappetadjustment 1pc ・Plugwrench 1pc

・Hexagonalwrench 1set ・Spannerfortappetadjustinglocknut 1pc ・Mufflerset 1set

・Ignitionsystem(w/sensor) 1set ・Sparkplug[SP-2](Attachedtotheengine) 1pc ・Anti-looseningnut 1pc

SwitchCapacity:3A〜

Sensor Battery

Voltage:6-12V

Capacity:1,000mA〜:

Plugcap

(2)Sensorcord

(Black)

(1)Plugcord

Mainunit

(3)BatteryCord

(Red/Black)

(4)Tachometercord

(Brown/Red/Orange)

FuelTank FuelLevel

ToOutsideoftheplane

Ventline

fuelsupplytocarburetor

Fuelfillerline

Ventline

Gasoline-compatible

tankstopper

Gasoline-compatibletubing

Filterwithweight

Closeaspossible(within200mm)

Hollowout

Firewall

CCWtomake

rich

Main

Needle

Throttle

Fullopen

SAITOSEISAKUSHO,CO.,LTD.www.saito-mfg.com

22-7,3-chome,Tokagi,Ichikawa-shi,Chibaprefecture272-0024,JapanPhone:047-378-4156FAX:047-378-4155

Allspecificationsandmodelsaresubjecttochangewithoutnotice.

Note:

●Asitusesoil-mixedfuel,theplanemaysometimesgetdirtyfromtheexhaust.

●Useareliableandwell-balancedprop.Otherwiseitmaycauseanabnormalvibrationandcouldresultinaseriousaccident.

●Duringoperation,allenginescrewscanloosenduetometalheatexpansion.Checkandtightenoccasionally.

●Whentheexhaustvalvegetsdullbycarbonorsludgeespeciallyincoldatmosphere,removetherockercoverandapplysomeanti-rust

spraytotheexhaustvalvetohelpthevalvetomovesmoothly.

●Payattentiontothesurroundingssoasnottodisturbothersbynoiseandexhaust.

●Alwayskeepspectatorsstandbehindtheenginewhenoperatingtheengine.

●Asexhaustsmokeisharmful,becarefulnottobreatheinorotherwiseexposeyourselftoitsharmfuleffects.

●Payattentionnottotouchtherotatingpropellerwhenstartingengine,andmovetorearsideoftheaircraftoncetheengineisstarted.

●Allresponsibilitiesfortheuseoftheengine,andotherobligationsandresponsibilitiesbasedonlaws,regulations,etc.arebornebythe

purchaserandtheuser,andSAITOSEISAKUSHOCO.,LTD.isexemptfromanyresponsibilities.

Warranty:

●Ifthereisanydeficiencyfromthefactoryconcerningmanufacture,pleaseconsultwiththeshopordistributoryouboughtfrom.Our

companywillberesponsibleforrepair.However,anyfailureortroublecausedbyunnecessarydisassembly,modification,orotheruses

thanthoseprovidedintheinstructionmanualisnotsubjecttowarranty.

●Ignitionsystemissubjecttothewarrantyonlyforinitialfailure.Oncethesystemhasbeenactivatedsuccessfully,itwillnolongerbesubject

towarranty.

ver.July,2021

1.Fuel

●Thefuelismixtureofregulargasolineorhigh-octanegasolineandhigh-quality2-strokeengineoil.

●[Exampleofoilrecommendation]

・KlotzKL-200OriginalTechniplate・DeluxeMaterialsPowerModel2T-S・ENEOSRACINGSPECPRO-2T(SAITOSTANDARD)etc.

Ifsuchoilsarenotavailableinyourcountry,thenpleaseasktheofficialSAITOdistributorinyourcountryforanalternative.

NEVERuse“cheapoil”designedforutilityenginesforbrushcutter,lawnmower,orchainsawetc.

●Besuretousethemixture“gasoline:oil=15~20:1”byvolumeratio.(Ex.1000mlofgasolineshouldbemixedwithmorethan50mlofoil).

●Duringthebreak-inprocess,use15:1mixedfueltoensurethebestlubricationforinitialrunning.

●Anydamagecausedbythefuelused,inwhichtheoilratioislowerthan20:1willnotbecoveredbywarranty.

●Donotusegasolinecontainingethanol.Itmaycausenotonlypowerlossbutalsocorrosioninsidetheengine.

3.Propeller

●RecommendedpropellerisAPC13x8~14x6whichbringsapprox.9,000rpm.Largersizeorgreaterpitchcancauseenginebrokendueto

overload.

●Useawell-balancedone.Neverusethepropellerthathasbeenscratchedordamagedevenifslightly.

●Asthepropelleriscompressedslightly,tightenthepropellernuteveryhourofoperation.

4.Break-inMOSTIMPORTANT!!

●Prop-recommendation:APC13x8.

●Use15:1fuel:oilratioforbreak-in.

●Nevermakethefuelmixtureleanduringbreak-in.Itcouldcauseseizureevenduringidlingor

low-speedrunning.

●Checkthattheslowneedleissettothereferenceposition.(Depth1.7~2.0mmfromthesurfaceof

thethrottlelever.)

●Beforestartingtheengine,openthemainneedleApprox.1+1/2turnsfromfullyclosed.

●Starttheengine(usingastarterisrecommendedforsafety).

●Soonafterstarting,Openthrottlegraduallyuptofull.InthemeantimeturnthemainneedleCCW.

ContinuetoturnthemainneedleCCWuntiltheRPMdeclines(toapprox4-5,000rpm)keeping

thethrottleopenedfully.

●Runinthisveryrichconditionfor1literoffuel.

●Now“initial”break-inisdone.

Slow High

Throttlelever

CCW→Rich

CC→Lean

Mainneedle

Slow(Idle)Needle

(Adjustwith⊖screwdriver)

CW→Lean

CCW→Rich

Approx.

1.7~2.0mm

SlowNeedle

5.Adjustmentofcarburetorafterinitialbreak-in.

◇Needlereferenceposition(Setafterinitialbreak-in)

●Starttheengineafteradjustingtheneedletothefollowingreferencevalue.

●Mainneedle:Approx.1+1/4~1+1/2turnsCCWfromfullyclosed

●Slowneedle:Approx.5+1/2turnsCW(Approx.2mm)fromthesurfaceofthethrottlelever.(Thenthrottlevalveshouldbefullyclosed)

●Actually,thebestpositionoftheneedlesvarydependingontheprop,

temperature,humidityandsoon.Pleaseadjustasnecessaryafter

observingtheengineperformanceduringflight.

◇Peakadjustment

●Afterstartingtheengine,warmupforapprox.30secondsatlowspeed.

●Achievethepeakatfullthrottle.

→TurnthemainneedleCWgraduallytothepositionwheretheRPMis

greatest(thepeak).ContinuingtoturntheneedleCWpastthepeak

couldleadtoseizuresoturnitslowlyandcarefully.IftheRPMsuddenly

decreasesafterpassingthepeak,instantlyturnthemainneedleCCW

toagainincreasetheRPM.Otherwiseitcoulddamagetheengine

seriously.

●OnceachievingpeakRPM,returnthethrottletolowspeed.Makeanoteofthepositionofmainneedleatthepeakatthattime.(Howmany

turnsyoudidCWbasedonthereferencevalue.)

◇SlowneedleAdjustment

●AfterachievingpeakRPM,nextisslowneedleadjustment.OpenthethrottlefromlowRPMtofullthrottlequickly.

●TurntheslowneedleCCWslightlyiftheenginehesitatesforamomentorstallsbeforetheenginereachesmaxRPMbecausethemixtureis

toolean.

●TurntheslowneedleCWslightlyiftheengineisslowtoreachpeakRPM(fullthrottleset)becausethemixtureistoorich.

●AdjusttheslowneedleasaboveuntiltheRPMfollowsthethrottlemovementsmoothly.Theimportantpointistoadjusttheslowneedle

AFTERthemainneedlehasbeenadjustedtoitspeak.

●Nowbreak-inatgroundlevelisdone.Adjusttappetsbythemethoddescribedlater.

◇Pre-flight/Flightadjustment

●Whentheslowneedleadjustmentisdone,checktheresponsebyrevvingupfromlowspeedtofullthrottlequicklyseveraltimes.

●OpenthethrottlefullyandturnthemainneedleCCWapprox.60〜90degreesfromthepeakposition.Thisistomakethefuelmixturericher

intheairwheretheRPMgethigherthanontheground.

●Afteralladjustmentsaremade,flyyouraircraftandfinetunetheengineaccordingtothesituation.Basicallytuningshouldbedonewiththe

mainneedle.Readjustmentoftheslowneedleisrarelyneededifthefirstadjustmentoftheslowneedlehasbeendonesuccessfully.

Voltage:6-12V,greaterthan1,000mA

※IfyouuseLi-Po,werecommendthespeclessthan2,500mAcapacityand

lessthan30Cdischargerate