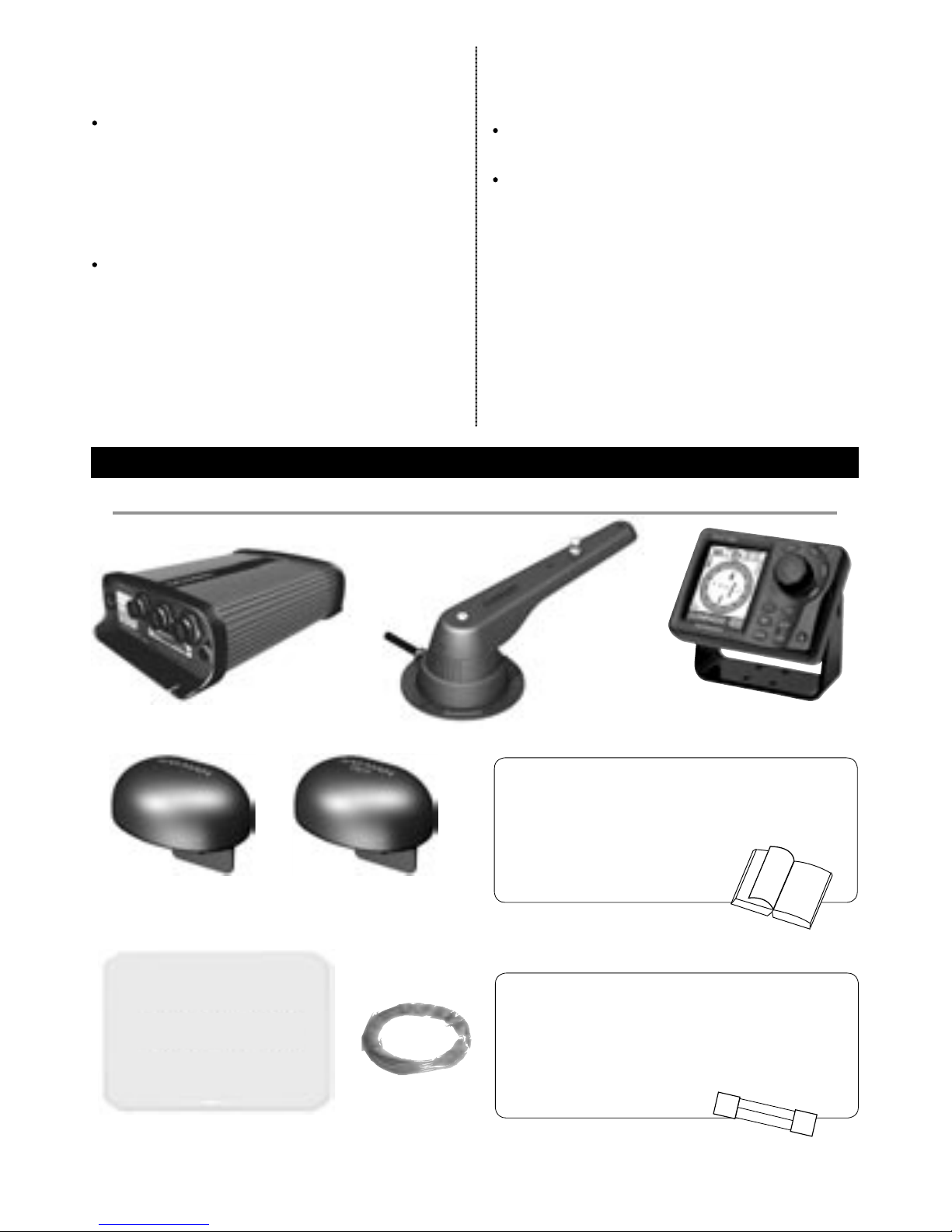

6 NAVMAN G-PILOT 3380 System Installation Manual

1-2 Using the G-PILOT 3380 system with other instruments

1-2-1 Using other instruments

The G-PILOT 3380 system can use data from

these instruments:

GPS: A GPS or chartplotter, such as a Navman

TRACKER 5000 series chartplotter must be

connected to the G-PILOT 3380 system for

the G-PILOT to operate in GPS mode (see the

G-PILOT 3380 Operation Manual).

Note: GPS must be via NMEA input.

WIND: A wind instrument, such as a

Navman WIND series, must be connected

to the G-PILOT 3380 system for the G-PILOT

to operate in WIND mode (see the G-PILOT

3380 Operation Manual).

SPEED: A speed instrument, such as:

Navman’s SPEED with a paddlewheel

speed sensor

or a GPS or chartplotter, such as

Navman’s TRACKER 5000 or TRACKFISH

6600 series can be connected to the

G-PILOT 3380 system to increase

steering accuracy.

Note: The speed from a paddlewheel sensor

is the speed that the boat is moving through

the water. The speed from a GPS is the speed

over the ground. If there is a water current

then these two speeds will be different. If

the G-PILOT 3380 system is connected to

an instrument with a paddlewheel sensor

and to a GPS, then the G-PILOT 3380 system

will automatically use the speed from the

paddlewheel sensor instrument.

1-2-2 NavBus

NavBus is a Navman proprietary system that

allows systems of multiple instruments to be

built using a single set of transducers. When

instruments are connected by NavBus:

If you change the units, alarms or

calibration in one instrument, then the

values will automatically change in all other

instruments of the same type.

Each instrument can be assigned to a

group of instruments, called a NavBus

group (see NavBus group in the Setup >

Comms menu, in the G-PILOT 3380 Operation

Manual). If you change the backlight in an

instrument in group 1, 2, 3 or 4 then the

backlight will automatically change in the

other instruments in the same group. If

you change the backlight in an instrument

in group 0 then no other instruments are

affected.

If an alarm sounds, mute it on any

instrument which can display that alarm.

For more information, refer to the NavBus

Installation and Operation Manual.

Note: GPS must be via NMEA input.

NavBus and the G-PILOT 3380 system

The G-PILOT 3380 system will automatically

work with additional G-PILOT 3380 displays

or G-PILOT 3100 displays.

The G-PILOT 3380 system can receive wind

data from Navman’s WIND over NavBus.

The G-PILOT 3380 system can receive speed

data from Navman’s SPEED over NavBus.

1-2-3 NMEA

NMEA is an industry standard, but is not as

flexible as NavBus as it requires dedicated

connections between instruments. The

G-PILOT 3380 system has one NMEA input port

and one port that can be configured to be an

input or an output (See G-PILOT 3380 Operation

Manual).

G-PILOT 3380 system NMEA inputs

GPS: The G-PILOT 3380 system can receive

NMEA GPS data from a compatible GPS or

chartplotter, such as Navman’s TRACKER 5000

series chartplotter:

XTE (from APA, APB or XTE sentences) is

required for the G-PILOT 3380 system to

use GPS mode

BRG (from APA sentences) and BOD (from

APA or APB sentences) are optional and

improve performance

COG (from VTG sentences) is optional and

can be displayed.