IMPORTANT

BEFORE USE READ THESE INSTRUCTIONS AND RETAIN FOR FUTURE REFERENCE

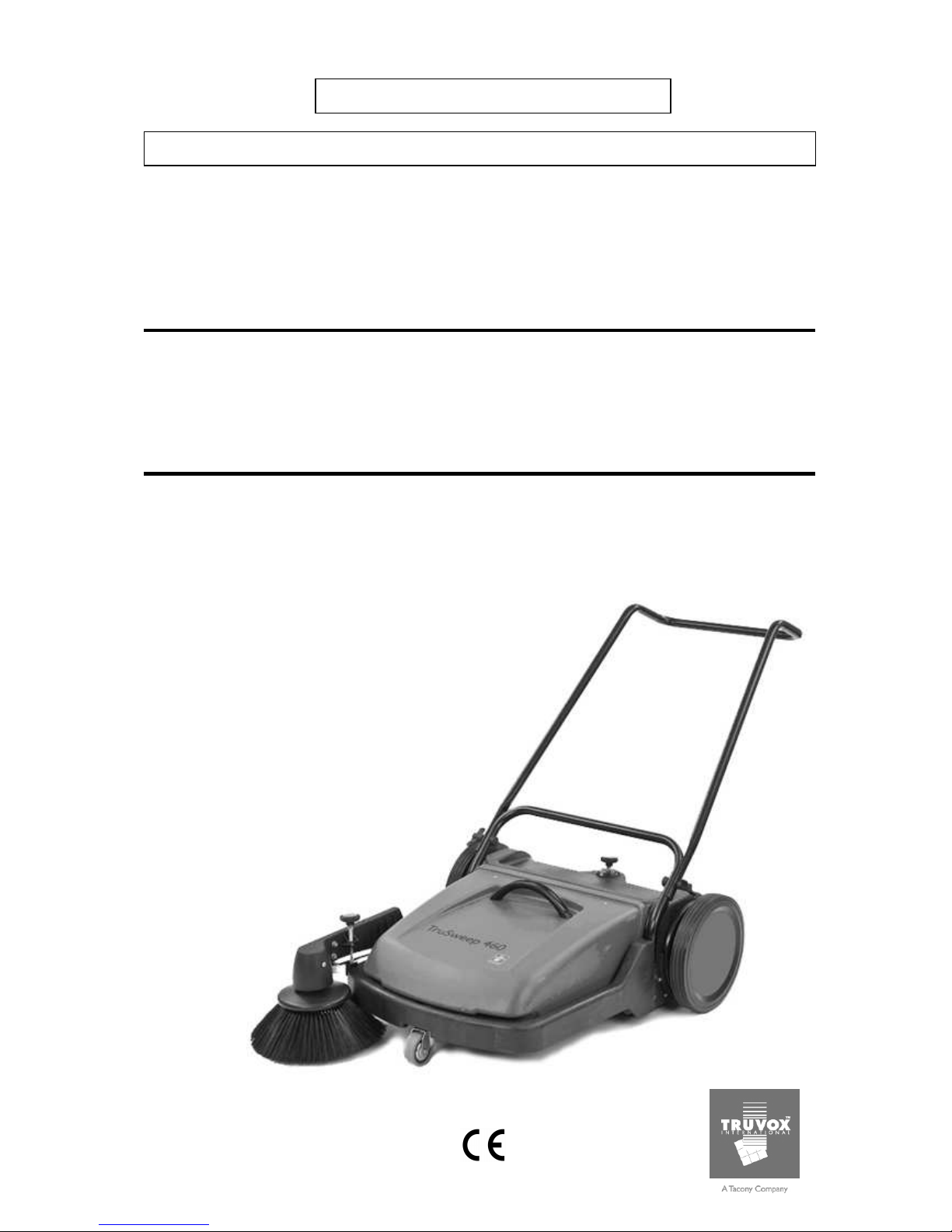

1. Product information

The TruSweep 460 is designed exclusively for

operation on solid, level and dry surfaces. It

has been designed for the professional user to

ensure long service life and safe operation.

These instructions only cover the operation of

the machine and do not include information on

the basics of sweeping. Any user not familiar

with basic sweeping methods should contact

their supervisor, supplier or Truvox

International before proceeding.

This machine must only be used for the

manufacturer’s approved application. This

sweeper is intended exclusively for operation

on solid, level and dry surfaces.

Do not use on a surface with a slope

exceeding 2%. Do not use the

machine where it is suspected that the surface

contains health endangering dust or debris

such as asbestos or chemical waste. If this is

suspected do not proceed, contact your

supervisor or Truvox International for advice.

The following instructions contain important

information about the machine and safety

advice for the operator.

Equipment must be operated, serviced and

maintained in accordance with the

manufacturer’s instructions. If in doubt

contact the supplier of your machine.

These instructions are valid for the following

model: TruSweep 460 – TRUS460

1.1 Important safety advice

When using the TruSweep 460 basic safety

precautions should be followed including the

following:

•Read all instructions carefully before use.

•Please note that the safety information

described in the manual supplements and

does not replace standards in force in the

country in which the machine is used.

•This appliance is suitable for commercial

use, for example in warehouses, hotels,

schools, hospitals, factories, shops, rental

businesses and other than normal

housekeeping purposes.

•Do not operate machine:

-Unless trained and authorized by a person

responsible for their safety.

-Unless operator manual is read and

understood.

-Unless with mentally, physically and the

sensory capability of following machine

instructions.

•Keep children and unauthorised persons

away from the machine when in use.

•All parts are to be positioned as indicated in

the instructions before using the machine.

•Do not operate the machine if it malfunctions

or is damaged in any way. Contact an

authorised service agent for repair or

adjustment.

•Keep hair, loose clothing, fingers and all

parts of body away from openings and

moving parts.

•Do not use where hazardous dust is

present.

•Do not use in an explosive

atmosphere.

•Do not pick up oil or other flammable

material.

•Take care when using a machine near the

top of stairs to avoid overbalancing.

1.2 Guidelines for the operator

WARNING - Operators must be fully

trained in the use of the machine in

accordance with these instructions,

able to perform user maintenance and the

correct selection of accessories.

•Operators should be physically capable to

manoeuvre, transport and operate the

machine.

•Operators should be able to recognise

unusual operation of the machine and report

any problems.

•Only use the machine on firm level surfaces

•Wear suitable footwear to avoid slipping.

•Wear suitable clothing to keep dry and

warm.

•Where possible implement job rotation and

adequate rest periods to avoid continuous

use of the same muscles.

•Do not smoke when using the machine.

•Do not put any objects into openings. Do not

use with any opening blocked: keep free of

dust, debris, hair, or anything that may

reduce air flow.

•Do not sweep over wet surfaces.

CAUTION - This machine is for use in

dry areas and should not be stored

outdoors or in wet conditions.

CAUTION - If it is suspected that there

is hazardous dust or flammable

materials stop cleaning the area

immediately and consult your superior.