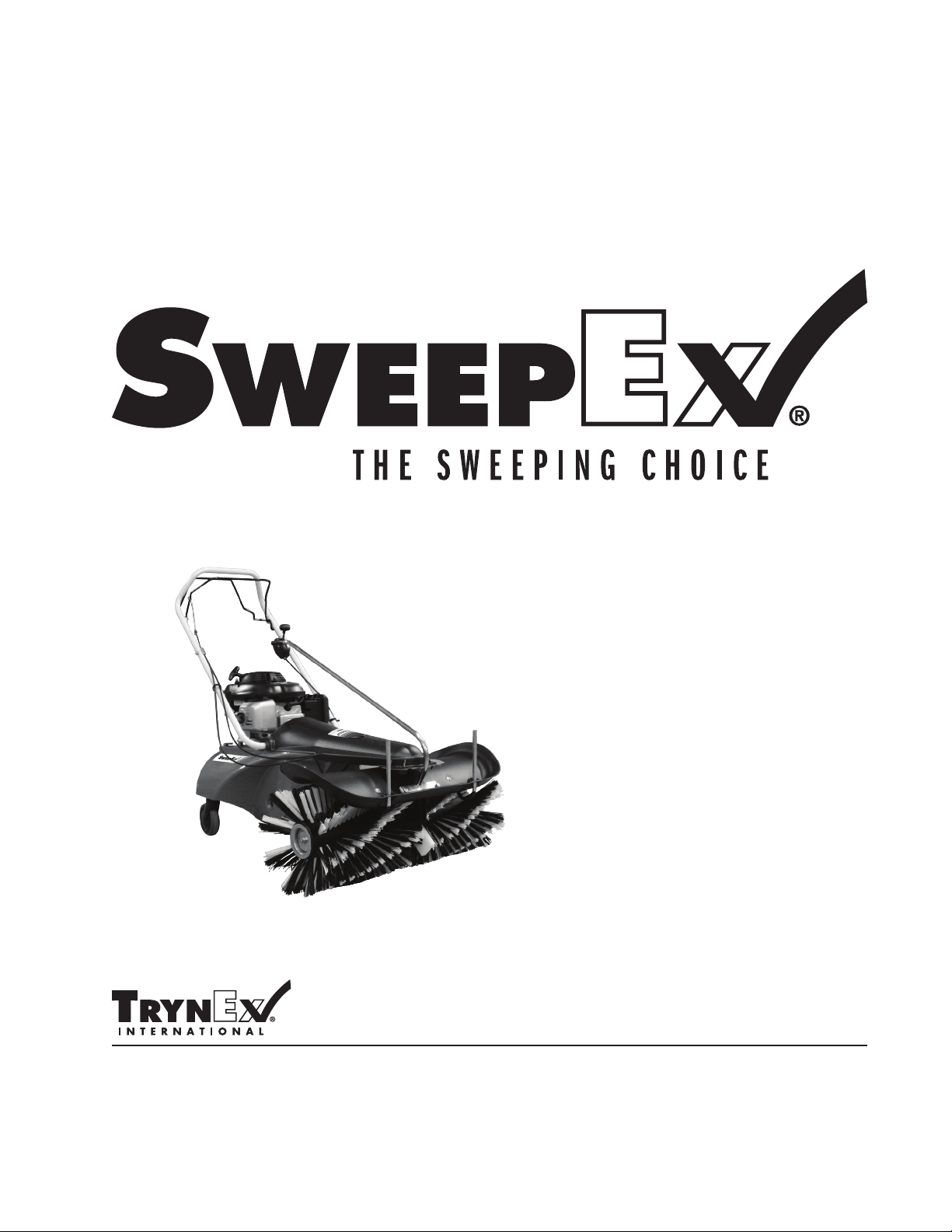

Trynex International SWB-320 User manual

Owner’s Manual

This Manual Must Be Read Before Operating The Equipment

© TrynEx International 2013

(REV A) F51225A

1

CUSTOMER COPY

Madison Heights, Michigan 48071

877-SWEEPEX

www.sweepexproducts.com

SWB-320

Serial No. R32-0913830001 and higher

2 © TrynEx International 2013 (REV A) F51225A

Table of Contents

Have a question or need assistance?

SweepEx Customer Care

877-SWEEPEX

or (248) 586-3500

Monday trough Friday 8:00 AM to 4:30 PM EST

Fax: (248) 691-8378

E-mail: customercare@trynexfactory.com

Website: www.sweepexproducts.com

Introduction .................................................................................................................................................................................................... 3

Safety..........................................................................................................................................................................................................4-5

Operating Instructions................................................................................................................................................................................6-15

Component Vocabulary ......................................................................................................................................................................... 6

General Safety ...................................................................................................................................................................................... 7

Operating in Winter............................................................................................................................................................................... 7

Operator Controls.................................................................................................................................................................................. 8

Starting/Stopping Motor........................................................................................................................................................................ 9

Adjusting Handlebar Height................................................................................................................................................................. 10

Transport ............................................................................................................................................................................................ 11

Adjusting Discharge Direction ............................................................................................................................................................. 12

Sweeping ........................................................................................................................................................................................... 13

Debris Collector Box (Optional Accessory) ........................................................................................................................................... 14

Debris Shield (Optional Accessory)...................................................................................................................................................... 15

Maintenance Instructions.........................................................................................................................................................................16-21

Oil and Gas ......................................................................................................................................................................................... 16

Tire Pressure ...................................................................................................................................................................................... 17

Adjusting Control Cables..................................................................................................................................................................... 18

Replacing/Changing Brushes .........................................................................................................................................................19-20

Maintenance Plan ............................................................................................................................................................................... 21

Cleaning ............................................................................................................................................................................................. 21

Troubleshooting ............................................................................................................................................................................................ 22

Notes............................................................................................................................................................................................................ 23

3© TrynEx International 2013 (REV A) F51225A

Introduction

This operating manual is intended to help you to get to know the SWB-320 and how to operate it safely, correctly and economically. If you

observe these instructions, you will prevent hazards, reduce repair costs and breakdown times, and increase the reliability and service life of

the machine.

This manual must be read and used in conformity to existing workplace regulations. The manual must be made available where the machine

is being used.

The manual must be read and used by every person who will be working with or on the machine, such as for

• Operation (including preparation, repair during operation, & clean-up)

• Repairs (maintenance, inspection, overhaul), and/or

• Transport.

All established technical regulations for safety and proper working practice must be observed in addition to this manual and any applicable

regulations for the prevention of accidents. Should you lose your Owner’s Manual or would like extra copies, they can be purchased at your

SweepEx dealer.

THIS SIGN SHOULD ALERT YOU:

This Safety Alert Symbol is used to pinpoint characteristics that, if not carefully followed, can create a safety

hazard. When you see this symbol in this manual or on the machine itself, be alert! Your personal safety and

the safety of others is involved.

Dened below are the Safety Alert Messages.

DANGER

Information that, if not carefully followed, can cause death.

WARNING

Information that, if not carefully followed, can cause serious personal injury or death.

CAUTION

Information that, if not carefully followed, can cause minor injury or damage to equipment.

IMPORTANT

This symbol is used to call out information that is important to follow carefully.

Note: Some of the photos in this manual may show the SWB-320 with an optional accessory or brush kit installed.

IMPORTANT EQUIPMENT INFORMATION

Record important machine information here for quick reference. This information can be found on the serial number plate located at the back

of the machine on the wheel drive enclosure.

Model _______________________________________

Serial # _______________________________________

Engine Model ________________________________

Engine Serial # ________________________________

Date Purchased ________________________________

Dealer where purchased

_______________________________________________

See separate Warranty Information Card for your warranty coverage.

Model: SWB-320

Engine: Honda GCV135

HP: 4.6

Weight: 130 lbs Manuf. 2013

Serial No. R32-0013830001

TrynEx International LLC

531 Ajax Drive

Madison Heights MI 48071

USA

Example

4 © TrynEx International 2013 (REV A) F51225A

Safety

See additional Safety Information at the beginning of Operating Instructions and Maintenance Instructions

Your SWB-320 is manufactured to state-of-the-art technical regulations. Despite this, it is possible that

operation will result in danger to life and limb for the operator or third parties, impairments to the machine

and other physical assets.

The machine is intended exclusively for use for brushing operations in property maintenance. Examples

of intended use are: snow clearing; sidewalk, driveway & parking lot cleaning; spring clean-up; dethatch-

ing; clearing debris from articial turf; and leaf clean-up. Any operation over and above these uses will be

considered as a non-intended use. SweepEx will not be held liable for any resulting damages. The operator

alone is responsible for any risk. Intended Use also includes observance of the Owner’s Manual and keeping

to all service and maintenance procedures.

Always keep the Owner’s Manual available at the machine’s place of work. In addition to this Owner’s

Manual, furnish all users with information regarding legal or other important regulations regarding accident

prevention. These duties can include handling hazardous materials; wearing personal safety equipment; and

trafc regulations. You should supplement this Owner’s Manual with instructions covering information related

to use of powered machinery; and operating equipment near people, other machines and trafc.

Do not smoke or have any open ame near the machine. Gasoline vapors could explode.

Only use the machine in perfect condition and according to applicable regulations. Be aware of your sur-

roundings and alert to what you are doing to reduce hazards. You should always repair faults which could

inuence the safety of the machine.

Personnel operating the machine must read the Owner’s Manual before using – especially all safety in-

formation. This includes people who occasionally work on or operate the machine such as for service and

transport. A clear understanding of how to operate the machine will reduce dangers involved with operating

powered equipment.

You must check that personnel operating the machine are paying attention to safety and hazards and under

observance of this Owner’s Manual. Operating personnel may not have long hair, or wear loose clothing or

jewelry, including rings – these items can catch and be pulled in by moving parts.

Keep all safety and hazard information for the machine complete and in readable condition. If the machine is

altered with regard to its safety or changes its operational behavior, stop operation immediately and report

the malfunction to the responsible department or person.

The SWB-320 may only be operated with brushes approved by SweepEx.

Do not carry out any alteration, addition or rebuilding to the machine which could inuence its safe opera-

tion. This especially applies to addition and alteration to safety devices and machine controls, and to welding

work on load-bearing components.

Personal protection equipment must be worn to prevent accidental injury. Observe all safety and hazard

information for the machine.

Rotating brushes cause ying debris, wear safety glasses with side protection.

Wear high-visibility clothing, especially when working around other machines, people and vehicles.

Be aware of and avoid pinch points when assembling and operating. Pinch points can exist around levers

and where two parts butt against each other.

Use barriers and trafc cones when working in areas of pedestrian and vehicle trafc to keep everything at a

safe distance.

Use genuine SweepEx parts for replacement. These meet the specic technical requirements. Observe all

deadlines indicated in the Owner’s Manual for maintenance checks and service

Suitable and adequate mechanic’s equipment is required for performing maintenance and service proce-

dures.

The SWB-320 is powered by gasoline. Know the location of re extinguishers and observe re safety proce-

dures.

This page contains safety information to highlight safety hazards and precautions involved with operating your SWB-320. This page must be

read and understood by all personnel who have any part with the assembly, use and care of this machine.

5© TrynEx International 2013 (REV A) F51225A

D

A

N

G

E

R

Z

O

N

E

Safety

PERSONNEL

Work on or with the machine may only be carried out by reliable personnel. Observe statutory minimum legal ages. Only operate the machine

with trained personnel.

Clearly dene personnel responsibility for operation, service and maintenance. Ensure the machine is operated only by authorized personnel

Determine machine operator responsibilities – including road trafc regulations.

Persons in training may only operate the machine under the supervision of an experienced operator.

Work on any part of this machine must be carried out by an experienced mechanic.

Work on drive mechanisms, brakes and steering equipment may only be carried out by suitably trained persons.

DANGER ZONE

Keep all bystanders away from the machine at least 30 feet (10 meters); out of the danger zone as described in the diagram below.

Flying objects; Keep safe distance

from the machine when engine is

running.

6 © TrynEx International 2013 (REV A) F51225A

Operating Instructions

Component Vocabulary

Receiver

Bar

Brush Angle

Adjustment

Engine

Drive Wheel

Caster

Wheels

Brushes

Handlebar

Throttle Control

Brush Lever

Movement

Lever

Drive

Wheels

7© TrynEx International 2013 (REV A) F51225A

Operating Instructions

General Safety / Operating in Winter

GENERAL SAFETY

Do not operate the machine in an unsafe manner! Make yourself familiar with the surroundings before start-

ing work in a new location. The working surroundings include any obstacles in the work area or on roads,

the ground load-bearing capacity and any necessary workplace safety precautions in live trafc.

Take precautions to ensure that the machine is only operated in a safe and functional condition! Only oper-

ate the machine if all protective and safety devices are present and working!

Check the machine for externally visible damage and faults before operation! If malfunctions occur stop

the machine and secure it immediately! Repair malfunctions immediately! Only start the machine from the

operator’s position! Ensure that no one can be endangered by starting the machine before switching it on or

operating it!

Check that braking, steering, and brushing are fully functional before operation!

Before operating the machine, always check that accessories are tted correctly! Always observe applicable

trafc regulations before operating on public roads, paths or parks, and ensure that the machine is in a

condition suitable for use in trafc

Always ensure that suitable lighting is available before working in poor light or darkness! Always keep a suf-

cient distance between the machine and drop-offs, holes or slopes!

Do not permit any method of working which will affect the stability of the machine!

Never traverse across slopes; always travel up and down, not across.

Adjust the speed to suit the conditions on inclines! Change gear before the incline, not on it! Always secure

the machine against rolling away and unauthorized operation before leaving it unattended!

OPERATING IN WINTER

Check regularly that the air lter is dry. If the air lter has become wet, let it dry overnight. There is a pos-

sibility of the engine not starting due to a clogged air lter.

Spray the throttle cable with silicone spray at both ends, and the throttle linkage before operating to prevent

the cable or throttle mechanism from freezing up.

Before putting the machine away, sweep it clear of snow.

Avoid freezing the machine. Store the machine in a frost-free room.

Silicone Spray attracts dust and binds it to the machine. It is only a suitable lubricant in wintry and snowy

conditions.

Do not spray Silicone Spray on hot engine. It could cause a re. Follow the instructions on the spray can.

Remove Foam Pre-Filter.

Use SAE 5W-30 Motor Oil.

8 © TrynEx International 2013 (REV A) F51225A

Operating Instructions

Operator Controls

If the brushes are switched on and the movement drive is not engaged, the machine can roll backwards.

The handlebar must be securely engaged at the required height.

Avoid injury and damage; Make completely sure that there are no persons or objects within the danger zone.

With long sleeves, the handlebar can get stuck inside the sleeve; This could prevent the drive from disen-

gaging and result in injury. Set the bar lower if wearing long sleeves or tightly button the sleeves.

HANDLEBAR CONTROLS

Drive

Brushes

Throttle

Start the machine forward by pressing the drive

clutch.

Engage both levers to operate the drive and the

brushes.

9© TrynEx International 2013 (REV A) F51225A

Operating Instructions

Starting/Stopping Motor

Never run the motor in an enclosed or conned space. The exhaust fumes contain poisonous gases.

Ensure that the transmission and brush are switched off before starting. The handlebar must be secure at

the required height.

Before starting the motor, ensure there is sufcient oil. The motor is not lled with oil when the machine is

delivered.

Move throttle lever to the choke

position.

Move throttle to the off position. Close Fuel Valve.

Pull starter coil. Stand behind

the handlebars. Do not press

any levers.

Make sure fuel valve is on.

STARTING

SHUTTING DOWN

10 © TrynEx International 2013 (REV A) F51225A

Operating Instructions

Adjusting Handlebar Height

There are four settings for adjusting the handlebar height. Push

the adjustment lever with your foot.

Adjust the handlebar to the desired position. Release the lever.

You can fold the handlebar forward to save space when storing.

11© TrynEx International 2013 (REV A) F51225A

Operating Instructions

Transport

CARRYING

SECURING FOR TRANSPORT

Carrying.

Position of Strap at the front.

To save space when transporting, fold the handlebars

forward.

Position of Straps at the rear.

Hand Position to hold front.

12 © TrynEx International 2013 (REV A) F51225A

Operating Instructions

Adjusting Discharge Direction

There are ve different settings available for the discharge direc-

tion.

Here: Forward Discharge Direction. The swept material will heap up

in front of the brushes. You should give preference to angled brush

settings.

With an angled setting, the material will be swept to one side.

Here: Material will be discharged to the left.

To adjust brush angle: Lift the lever; Turn the brush in the desired

direction; Release the lever and ensure the lever is latched in

place.

Here: Material will be discharged to the right.

A sideways setting is recommended if using the optional Debris

Collector Box. This will allow sweeping against a wall or curb.

A sideways setting is recommended if using the optional Debris

Shield. This will allow sweeping against a wall or curb.

13© TrynEx International 2013 (REV A) F51225A

Operating Instructions

Sweeping

Lift up the brushes by pushing down on the handlebars. Engage

the brushes.

Engage the movement drive. Just follow behind the machine.

Carefully lower the brushes to the ground.

Set the speed by using the throttle lever. Do not try to hold the

machine back or push it.

IMPORTANT

The pressure adjusts automatically to the ground prole. However, you can inuence the brush pressure by either pulling back

or pushing on the handlebar. Pulling the handlebar back decreases the pressure; pushing will increase the pressure (for heavily

soiled areas).

When sweeping dust, use a low brush speed (low throttle).

When using the Debris Collector Box or the Debris Shield, use a medium speed (half-throttle).

If the brush pressure is too heavy, the cleaning effect is decreased because the brush bers are bent too much.

14 © TrynEx International 2013 (REV A) F51225A

Operating Instructions

Debris Collector Box (Optional Accessory)

SWB-320 with Debris Collector Box (DCB-320).

Mount as shown below, paying attention to the

alignment with brush hood.

To dump the debris into a separate

container, remove the Collector Box from

the sweeper and use the handle to tow it

to your other container.

To dump the debris, simply pull the

handle from the operating position so the

debris can fall out.

15© TrynEx International 2013 (REV A) F51225A

Operating Instructions

Debris Shield (Optional Accessory)

SWB-320 with Debris Shield (PCA-320).

Slide the Debris Shield over the receiver

bars.

Slide one fender washer over each

receiver bar.

Finished.

16 © TrynEx International 2013 (REV A) F51225A

Maintenance Instructions

Oil and Gas

Capacities:

Oil 0.58 quarts (0.55 L)

Gasoline 0.95 gal (0.9 L)

Use 86 octane or higher unleaded gasoline.

Gas

Oil

1. Remove oil cap; wipe dipstick clean.

2. Replace dipstick in the oil ller neck; do not screw down.

3. Remove dipstick; check oil level. The oil should be up to the upper

marking.

4. If oil level is low, ll up to the upper marking on the dipstick with

the recommended oil (see Honda Owner’s Manual).

5. See marking on the dipstick for ll level.

FILL LEVEL

17© TrynEx International 2013 (REV A) F51225A

Maintenance Instructions

Tire Pressure

IMPORTANT

If the tire pressure is too low, the inner-tube will rub against the wheel and be damaged.

Over-Ination can cause the tire to burst.

Check the tire pressure regularly.

Lock the handlebar at the front-most setting. Tip the machine backward to rest on the handlebar and the rear

wheels. Have a second person hold the machine in this position.

Turn the wheel counter-clockwise to expose the valve stem. Inate the tire to 35 psi (2.5 bar)...or if you are going to sweep

rough surfaces – 30 psi (2 bar).

18 © TrynEx International 2013 (REV A) F51225A

Maintenance Instructions

Adjusting Control Cables

IMPORTANT

It may be necessary to reset the cables after machine has been operating for a few hours.

The cables need reset if the levers move more than one-third of the lever’s travel without resistance.

Loosen the nut that holds the cable to the handlebar with a 10 mm

wrench. Pull the cable down. Re-tighten nuts.

The levers should move one-third of the total travel without

resistance. The lever should be operating the cable for the other

two-thirds.

The drive wheel should just turn when the lever is not engaged.

19© TrynEx International 2013 (REV A) F51225A

Maintenance Instructions

Replacing/Changing the Brushes

Note:

If replacing the Multi-

Purpose Brushes, or

changing to them: The

black row of bristles must

touch the ground before

the white row when the

brush rotates.

Note:

For any other bristle kit,

the bristle rows should

be curving upward from

the left (looking from the

front).

Note: Multi-Purpose

Bristle shown for clarity.

4. Remove the axle with

the second brush.

2. Tip the machine up.

Have a second person

stabilize the machine.

3. Remove the nut and

pull off the brush.

5. Parts after disas-

sembly.

1. Loosen the nut on the

left brush (when viewed

from the front) – use two

17 mm wrenches.

Continued on next page...

IMPORTANT

Check the brushes after every 20 hours use. The brushes must be replaced if you are no longer satised with the brushing

result, or if the brush diameter is below 8-5/8 inches (220 mm).

Right

Brush

Axle

Cap

Nut Washer

Cap

Left

Brush

20 © TrynEx International 2013 (REV A) F51225A

Maintenance Instructions

Replacing/Changing the Brushes

6. Assemble the right-

hand brush with the axle

to the sweeper.

7. The tab on the cap-

gear should t into the

slot of the brush cylinder.

8. Fit the left-hand brush

over the axle.

9. Install the cap and

washer, ensuring the tabs

and slots are aligned.

10. Tighten the locknut

to fasten the brushes.

TAB

SLOT

Table of contents