TSI Incorporated 3480 User manual

Aerosol Generators

Model 3480

Electrospray Aerosol Generator

User’s Manual

P/N 1933793, Revision E

March 2008

Product Overview 1

Unpacking and Setting

Up the System

2

Controls, Indicators, and

Connectors

3

Operating the

Electrospray

4

Model 3480

Electrospray

Aerosol Generator

User’s Manual

Maintenance 5

Troubleshooting 6

Contacting Customer

Service

7

Appendixes

iv

Manual History

The following is a manual history of the Model 3480 Electrospray

Aerosol Generator (Part Number 1933793).

Revision Date

Preliminary Version March 1999

Final May 1999

A July 2000

B February 2002

C October 2002

D October 2003

E March 2008

In Revision A, TSI’s Limitation of Warranty and Liability was

updated.

In Revision B, Table 2-1 was updated, Appendix C was removed,

and a few minor corrections were made throughout manual.

In Revision C, TSI’s phone numbers and address were updated.

Front and back manual covers were updated.

In Revision D, directions for replacing the capillaries were updated

due to a change to the capillary design. Miscellaneous changes

were made throughout manual and pictures were updated.

In Revision E, manual was updated with new logo and look. The

equation used for calculating final particle diameter Dpwhen using

a sucrose solution with the Electrospray was corrected and

simplified. Relationship between viscosity of solution and

concentration was removed from the discussion and reader was

referred to a related publication for more information.

v

Warranty

Part Number 1933793 / Revision E / March 2007

Copyright ©TSI Incorporated / 2008 / All rights reserved.

Address TSI Incorporated / 500 Cardigan Road / Shoreview, MN 55126 / USA

Fax No. 651-490-3824

Limitation of Warranty

and Liability

(effective July 2000)

Seller warrants the goods sold hereunder, under normal use and service as

described in the operator's manual, shall be free from defects in workmanship and

material for (12) months, or the length of time specified in the operator's manual,

from the date of shipment to the customer. This warranty period is inclusive of any

statutory warranty. This limited warranty is subject to the following exclusions:

a. Hot-wire or hot-film sensors used with research anemometers, and certain other

components when indicated in specifications, are warranted for 90 days from

the date of shipment.

b. Parts repaired or replaced as a result of repair services are warranted to be free

from defects in workmanship and material, under normal use, for 90 days from

the date of shipment.

c. Seller does not provide any warranty on finished goods manufactured by others

or on any fuses, batteries or other consumable materials. Only the original

manufacturer's warranty applies.

d. Unless specifically authorized in a separate writing by Seller, Seller makes no

warranty with respect to, and shall have no liability in connection with, goods

which are incorporated into other products or equipment, or which are modified

by any person other than Seller.

The foregoing is IN LIEU OF all other warranties and is subject to the LIMITATIONS

stated herein. NO OTHER EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR

PARTICULAR PURPOSE OR MERCHANTABILITY IS MADE.

TO THE EXTENT PERMITTED BY LAW, THE EXCLUSIVE REMEDY OF THE USER

OR BUYER, AND THE LIMIT OF SELLER'S LIABILITY FOR ANY AND ALL LOSSES,

INJURIES, OR DAMAGES CONCERNING THE GOODS (INCLUDING CLAIMS BASED

ON CONTRACT, NEGLIGENCE, TORT, STRICT LIABILITY OR OTHERWISE) SHALL

BE THE RETURN OF GOODS TO SELLER AND THE REFUND OF THE PURCHASE

PRICE, OR, AT THE OPTION OF SELLER, THE REPAIR OR REPLACEMENT OF THE

GOODS. IN NO EVENT SHALL SELLER BE LIABLE FOR ANY SPECIAL,

CONSEQUENTIAL OR INCIDENTAL DAMAGES. SELLER SHALL NOT BE

RESPONSIBLE FOR INSTALLATION, DISMANTLING OR REINSTALLATION COSTS

OR CHARGES. No Action, regardless of form, may be brought against Seller more

than 12 months after a cause of action has accrued. The goods returned under

warranty to Seller's factory shall be at Buyer's risk of loss, and will be returned, if at

all, at Seller's risk of loss.

Buyer and all users are deemed to have accepted this LIMITATION OF WARRANTY

AND LIABILITY, which contains the complete and exclusive limited warranty of

Seller. This LIMITATION OF WARRANTY AND LIABILITY may not be amended,

modified or its terms waived, except by writing signed by an Officer of Seller.

Service Policy Knowing that inoperative or defective instruments are as detrimental to TSI as they

are to our customers, our service policy is designed to give prompt attention to any

problems. If any malfunction is discovered, please contact your nearest sales office

or representative, or call TSI’s Customer Service department at 1-800-874-2811

(USA) or (651) 490-2811.

vii

Contents

Manual History ......................................................................iv

Warranty.................................................................................v

Safety ....................................................................................xi

Labels ..................................................................................... xi

Description of Caution/Warning Symbols .............................. xii

Caution ............................................................................... xii

Warning ............................................................................. xiii

Caution or Warning Symbols.............................................. xiii

Radiation Safety.................................................................... xiii

Chemical Safety .....................................................................xiv

Electrical Safety ......................................................................xv

About This Manual .............................................................. xvii

Purpose.................................................................................xvii

Related Product Literature ....................................................xvii

Getting Help..........................................................................xvii

Submitting Comments .........................................................xviii

CHAPTER 1 Product Overview..............................................1-1

Product Description ..............................................................1-1

Applications ..........................................................................1-2

How the Electrospray Operates .............................................1-2

CHAPTER 2 Unpacking and Setting Up the System...............2-1

Packing List ..........................................................................2-1

Mounting the Instrument ......................................................2-2

Ventilation Requirements ...................................................2-2

Checking the Zero of the Pressure Gauge ...........................2-3

Power Connection .................................................................2-3

Analog Output ......................................................................2-4

Filtered Air Input ..................................................................2-4

CO2Input..............................................................................2-4

Installing the Ionizer .............................................................2-5

CHAPTER 3 Controls, Indicators, and Connectors ................3-1

Front Panel ...........................................................................3-1

LED Displays .....................................................................3-1

Voltage Adjustment Knob ...................................................3-2

Indicators...........................................................................3-2

Rotameters.........................................................................3-3

Pressure Regulator and Gauge ...........................................3-3

Pressure Chamber..............................................................3-3

Viewing Window .................................................................3-3

Ionizer Retainer ..................................................................3-3

Back Panel ............................................................................3-4

Aerosol Exit........................................................................3-4

Analog Output....................................................................3-5

viii Model 3480 Electrospray Aerosol Generator

AC Power Connector........................................................... 3-5

Filtered Air Inlet .................................................................3-5

CO2Inlet ............................................................................3-5

Internal Components ............................................................3-6

Capillary ............................................................................3-6

Electrospray Chamber........................................................3-6

High-Voltage Fitting and Shield .......................................... 3-6

Power Supply .....................................................................3-7

Main PCB...........................................................................3-7

High-Voltage Supply Module ..............................................3-7

Interlock Switch .................................................................3-8

Filters ................................................................................3-8

CHAPTER 4 Operating the Electrospray ............................... 4-1

Preparing Samples ................................................................4-1

Preparing a Buffer Solution ................................................4-2

Measuring and Adjusting Conductivity...............................4-2

Measuring and Adjusting pH ..............................................4-3

Typical Solutes...................................................................4-3

Starting Up the Electrospray .................................................4-5

Generating Aerosols ..............................................................4-6

Changing Samples ................................................................4-8

Shutting Down the Electrospray............................................4-8

CHAPTER 5 Maintenance..................................................... 5-1

Periodic Maintenance ............................................................5-1

Purging the Capillary..........................................................5-1

Cleaning the Orifice Plate ...................................................5-3

Cleaning the Aerosol Exit Port ............................................5-4

Cleaning the Viewing Window Lens ....................................5-4

Replacing the Ionizer .......................................................... 5-5

Cleaning the Electrospray Chamber ...................................5-6

Performing an Air Leak Test ...............................................5-8

Cleaning the Pressure Chamber .......................................5-10

Special Maintenance ...........................................................5-12

Removing the Capillary ....................................................5-12

Cleaning the Capillary Tip ................................................5-14

Installing the Capillary .....................................................5-14

Adjusting the Position of the Capillary Tip........................5-15

Adjusting the Position of the Capillary and the

Platinum Wire in the Pressure Chamber........................ 5-15

Reversing the High-Voltage Polarity.................................. 5-16

Cleaning the Pressure Regulator ......................................5-19

Cleaning the Rotameters ..................................................5-19

Replacing the Filters.........................................................5-19

Replacement Parts ..............................................................5-19

CHAPTER 6 Troubleshooting................................................ 6-1

Electrospray Operation is Unstable .......................................6-1

Unplugging the Capillary.......................................................6-3

Applying Back Pressure to the Capillary.............................6-3

CHAPTER 7 Contacting Customer Service............................ 7-1

Technical Contacts................................................................ 7-1

Returning the Electrospray for Service ..................................7-1

Contents ix

APPENDIX A Model 3480 Specifications ...............................A-1

Pressure Regulator Maintenance ........................................A-2

Rotameter Maintenance......................................................A-3

APPENDIX B Theory of Operation.........................................B-1

System Description .............................................................. B-1

Capillary Flow Characteristics.............................................. B-2

Calculating Primary Droplet Diameter.................................. B-4

Electrospray Chamber.......................................................... B-4

Equilibrium Charging Theory ............................................... B-5

Air and CO2Flow Control ..................................................... B-7

Voltage and Current Measurement....................................... B-9

Voltage Measurement ........................................................ B-9

Current Measurement ....................................................... B-9

Selected References.............................................................. B-9

Index

Reader’s Comments

Figures

S-1 Location of Warning and Information Labels.......................xii

1-1 Model 3480 Electrospray Aerosol Generator ..................... 1-1

2-1 Bottom View of Electrospray Aerosol Generator Showing

Location of Rubber Feet................................................. 2-2

2-2 Installing the Ionizer......................................................... 2-6

3-1 Front Panel of the Model 3480 Electrospray Aerosol

Generator ...................................................................... 3-2

3-2 Back Panel of the Model 3480 Electrospray Aerosol

Generator ...................................................................... 3-4

3-3 ANALOG OUTPUT Pin Designations.................................. 3-5

3-4 Main Internal Components ............................................... 3-7

4-1 Inserting a Sample Vial into the Pressure Chamber .......... 4-6

4-2 Three Views of Capillary Tip Through the Viewing

Window ......................................................................... 4-7

5-1 Inlet Fitting....................................................................... 5-3

5-2 Viewing Window Assembly................................................ 5-5

5-3 Cleaning the Electrospray Chamber.................................. 5-7

5-4 Cleaning the Pressure Chamber ..................................... 5-11

5-5 Removing or Installing the Capillary ............................... 5-13

5-6 Determination of High-Voltage Polarity ........................... 5-17

5-7 Reversing the High Voltage Polarity ................................ 5-18

B-1 Schematic Diagram of the Electrospray ............................ B-2

B-2 Bipolar Particle Charge Distribution in Air

[Wiedensohler and Fissan, 1988] ................................... B-5

B-3 Electrospray Flow Schematic............................................ B-8

x Model 3480 Electrospray Aerosol Generator

Tables

2-1 Electrospray Packing List ................................................. 2-1

3-1 Signal Connections for Analog Output Configurations ...... 3-5

4-1 Selected Proteins and Their Diameters.............................. 4-5

5-1 Maintenance Schedule...................................................... 5-1

5-2 Replacement Parts.......................................................... 5-19

6-1 Troubleshooting if the Electrospray Operation is

Unstable........................................................................ 6-2

6-2 Troubleshooting if the Capillary has Become Plugged ....... 6-3

A-1 Specifications of the Model 3480 Electrospray Aerosol

Generator ...................................................................... 8-1

B-1 Capillary Flow Characteristics for Water at 20°C .............. B-3

B-2 Midpoint Particle Diameters and Fraction of Total

Particle Concentration that Carries +1, +2, +3, and

+4 Elementary Charges ................................................. B-6

B-3 Coefficients for Equation B-4............................................ B-7

xi

Safety

This section gives instructions to promote safe and proper handling

of the Model 3480 Electrospray Aerosol Generator.

There are no user serviceable parts inside the instrument. Refer all

repair and maintenance to a qualified technician. All maintenance

and repair information in this manual is included for use by a

qualified technician.

To prevent problems, take these precautions:

Do not remove any parts from the instrument unless you are

specifically told to do so in this manual.

Do not remove the instrument housing or covers while power is

supplied to the instrument.

!

Caution

If the Model 3480 is used in a manner not specified by the manufacturer,

the protection provided by the equipment may be impaired.

WARNING

High voltage is accessible in several locations within this instrument.

Make sure you unplug the power source before removing the cover or

performing maintenance procedures.

Labels

The Electrospray has the eight labels shown in Figure S-1. They are

described below starting from the bottom-right and moving

clockwise.

1. High-Voltage Symbol Label (interior, on high-voltage power

supply shield)

2. High-Voltage Symbol Label (interior, on power supply)

3. High-Voltage Symbol Label (interior, on power entry module)

4. Ground Symbol Label (interior, bottom, next to ground stud)

5. Caution, No User Serviceable Parts…Label (back of cabinet)

xii Model 3480 Electrospray Aerosol Generator

6. Customer Service Label (back of cabinet)

7. Serial Number Label (back of cabinet)

8. High-Voltage Symbol Label (interior, on high-voltage fitting

shield)

Figure S-1

Location of Warning and Information Labels

Description of Caution/Warning Symbols

The following symbol and an appropriate caution statement are

used throughout the manual and on the Model 3480 to draw

attention to any steps that require you to take cautionary measures

when working with the Model 3480:

Caution

!

Caution

Caution means be careful. It means if you do not follow the procedures

prescribed in this manual you may do something that might result in

equipment damage, or you might have to take something apart and start

over again. It also indicates that important information about the operation

and maintenance of this instrument is included.

Safety xiii

Warning

!

WARNING

Warning means that unsafe use of the instrument could result in serious

injury to you or cause irrevocable damage to the instrument. Follow the

procedures prescribed in this manual to use the instrument safely.

Caution or Warning Symbols

The following symbols may accompany cautions and warnings to

indicate the nature and consequences of hazards:

Warns you that uninsulated voltage within the instrument may

have sufficient magnitude to cause electric shock. Therefore,

it is dangerous to make any contact with any part inside the

instrument.

Warns you that the instrument is susceptible to electro-static

dissipation (ESD) and ESD protection procedures should be

followed to avoid damage.

Indicates the connector is connected to earth ground and

cabinet ground.

Warns you that the Model P-2042 Nuclespot Local Air

Ionizer, which is installed inside the Model 3480 Electrospray

Aerosol Generator, contains Polonium-210, a radioactive

material that is subject to the regulations of the U.S. Nuclear

Regulatory Commission and local regulations. Carefully read

the Model P-2042 Literature provided with the ionizer to

determine your legal responsibilities regarding the ionizer.

Radiation Safety

The Electrospray Aerosol Generator contains a Model P-2042

Nuclespot Local Air Ionizer with a Polonium-210 source. Under

normal circumstances, you will not come into contact with

hazardous radiation. However, take these precautions when

operating the Electrospray:

xiv Model 3480 Electrospray Aerosol Generator

The Model P-2042 Nuclespot Local Air Ionizer with a Polonium-210

source must be installed in the Electrospray for it to operate properly.

Po-210 is subject to the regulations of the U.S. Nuclear Regulatory

Commission and local regulations. Carefully read the safety information

provided with the ionizer to determine your legal responsibilities regarding

the ionizer.

WARNING

The use of controls, adjustments, or procedures other than those

specified in this manual may result in exposure to hazardous radiation.

Corrosive materials can degrade the protective coating of gold

on the ionizer inside the Electrospray. Do not operate the

Aerosol Generator with chemicals that corrode gold.

Do not operate the Aerosol Generator at temperatures above

50°C. Excess temperatures may damage the ionizer, resulting in

radioactive contamination.

The ionizer must be returned after 12 months. Contact TSI for

information and instructions on returning the ionizer.

Do not remove any parts from the Electrospray unless you are

specifically told to do so in this manual.

Chemical Safety

Observe these warnings when operating the Electrospray Aerosol

Generator:

!

WARNING

Any material or procedure mentioned in this manual is intended for use by

qualified professionals familiar with potential chemical hazards and

trained in safe laboratory procedures.

!

WARNING

Corrosive materials can degrade the stainless steel and aluminum

chamber inside the Electrospray Aerosol Generator. Do not operate the

Electrospray with chemicals that corrode stainless steel or aluminum.

Safety xv

!

WARNING

High concentrations of aerosols can be hazardous. Use a filter at the

Electrospray exit if the generated aerosol is not being used by another

instrument or in another application.

Electrical Safety

The Electrospray Aerosol Generator contains a high-voltage source

on the inside of the instrument. Under normal circumstances, you

will not come into contact with hazardous voltage. However, always

remove power from the Electrospray before removing the cover from

the instrument.

WARNING

High voltage is accessible in several locations within this instrument.

Make sure you unplug the power source before removing the cover or

performing maintenance procedures.

xvii

About This Manual

Purpose

This is an instruction manual for the operation and handling of the

Model 3480 Electrospray Aerosol Generator.

Related Product Literature

Model 3080 Electrostatic Classifier Manual (part number

1933792 TSI Incorporated)

Model 3010 Condensation Particle Counter Manual (part number

1933010 TSI Incorporated)

Model 3022A Condensation Particle Counter Manual (part

number 1933763 TSI Incorporated)

Model 3025A Ultrafine Condensation Particle Counter Manual

(part number 1933762 TSI Incorporated)

Model 3936 SMPS (Scanning Mobility Particle Sizer) Manual (part

number 1933796 TSI Incorporated)

Model 3068 Aerosol Electrometer Manual (part number 1933068

TSI Incorporated)

Getting Help

To obtain assistance with this product or to submit suggestions,

please contact TSI:

TSI Incorporated

500 Cardigan Road

Shoreview, MN 55126 U.S.A.

Fax: (651) 490-3824

Telephone: 1-800-874-2811 (USA) or (651) 490-2811

xviii Model 3480 Electrospray Aerosol Generator

Submitting Comments

TSI values your comments and suggestions on this manual. Please

use the comment sheet, on the last page of this manual, to send us

your opinion on the manual’s usability, to suggest specific

improvements, or to report any technical errors.

If the comment sheet has already been used, send your comments

to:

TSI Incorporated

500 Cardigan Road

Shoreview, MN 55126 U.S.A.

Fax: (651) 490-3824

1-1

CHAPTER 1

Product Overview

This chapter describes the Model 3480 Electrospray Aerosol

Generator and gives an overview of how it works.

Product Description

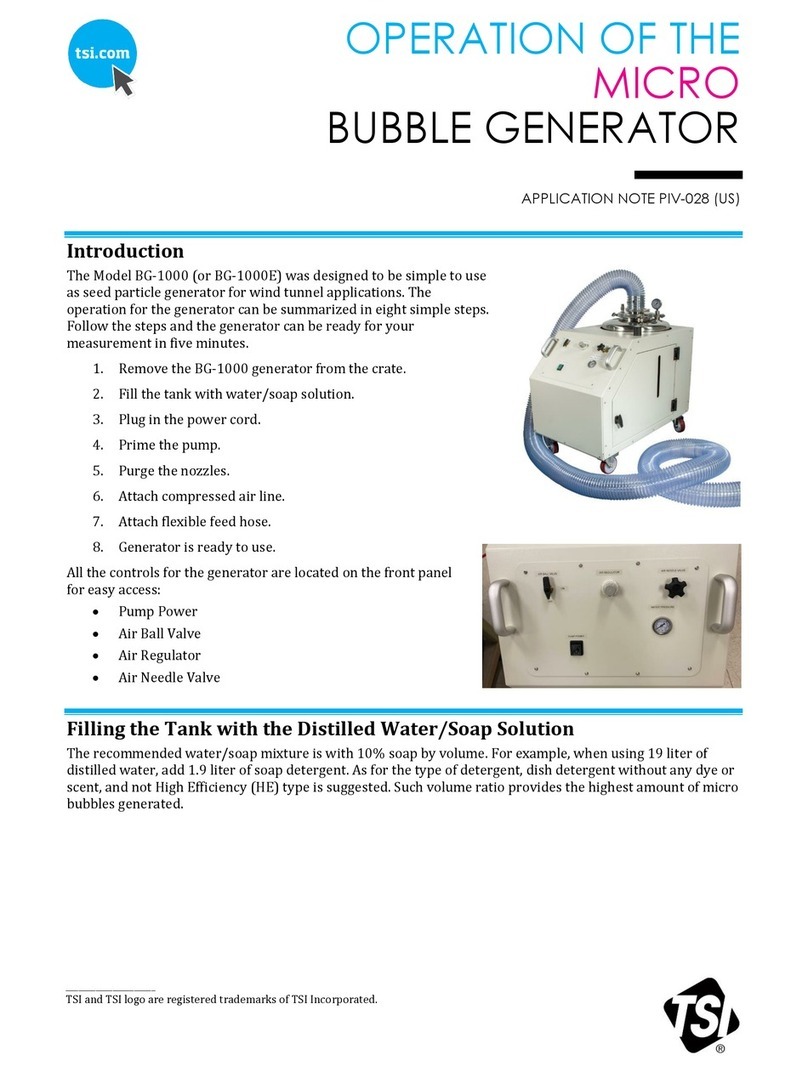

The Model 3480 Electrospray Aerosol Generator, shown in

Figure 1-1, generates monodisperse aerosols in the size range of 2

to 100 nanometers. Beginning with a liquid and adding a solute to

form a solution or suspension, the Electrospray converts the

sample to an aerosol by charging the liquid, pushing it through a

capillary, and exerting an electric field at the capillary tip. The

liquid evaporates from the droplets formed at the capillary tip while

the charge on each droplet is reduced by an ionizer.

In addition to the vast combination of solutes that could be used in

the Electrospray to generate aerosols, the user has the ability to

control the liquid flow rate through the capillary, the intensity of

the electric field at the capillary tip, and the amount of time the

aerosol is exposed to the ionizer.

Figure 1-1

Model 3480 Electrospray Aerosol Generator

1-2 Model 3480 Electrospray Aerosol Generator

Applications

The successful use of the electrospray method to generate

monodisperse aerosol has been documented in many publications.

Although the basic principles are well understood, many of the

details explaining how different operating parameters affect the

electrospray method remain to be discovered. Known applications

for this instrument include:

Studies of nano-aerosols

Instrument calibration

Dispersion of nanometer-sized powders for nano-powder sizing

Aerosol analysis in the macromolecular and submicrometer

range

Research involving parameters that influence the electrospray

method

How the Electrospray Operates

A sample solution is stored in a cone-shaped vial, enclosed in a

cylindrical pressure chamber. The chamber accommodates a

capillary and a high-voltage, platinum wire, both of which are

immersed in the solution. A differential pressure causes the

solution to be pushed through the capillary.

An electrical field pulls the charged solution out of the capillary

exit, forming droplets that are mixed with clean air and CO2. This

produces a sheath flow, which transports the droplets to the

Electrospray chamber. The highly charged droplets are neutralized

by a radioactive ionizer (Polonium-210), and the liquid is

evaporated before the aerosol exits the instrument.

Table of contents

Other TSI Incorporated Inverter manuals