USER GUIDE FOR MTR-X SET

Publication 696-082 RevA ©2022 TSO Products LLC Page 2 of 2

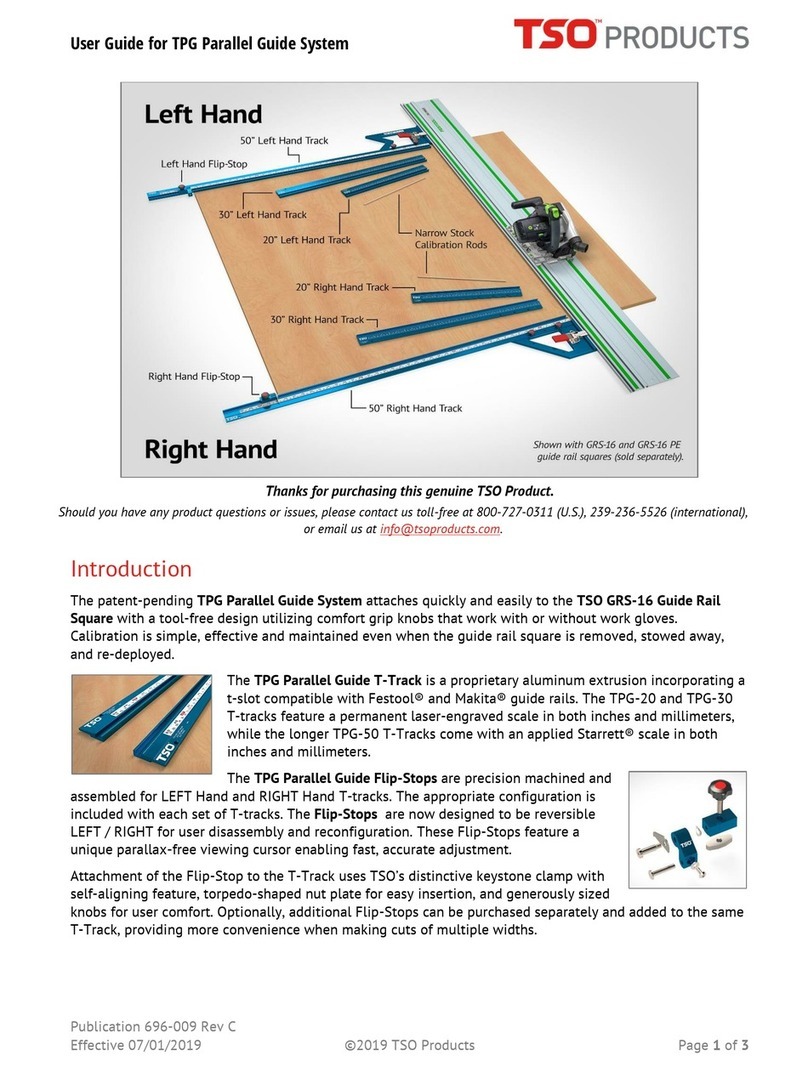

More Applications for Your MTR-X Set

See below for common applications of the MTR-X Preci-

sion Multifunction Triangle. Got an application we havenʼt

listed here? Weʼd love to hear about it!

Referencing Offthe Edge

Attach the Edge Index Pins

to the face of the triangle to

form a projected shoulder,

useful for quickly referenc-

ing the edge of your work-

piece as shown here. When

not needed, store these

pins in the Small Parts Tin.

Variable Angle Workpiece Marking

First, configure the MTR-X

with its protractor assem-

bly installed. Place the

triangle on top of your

workpiece. With both

Triangle Dogs touching the

front edge of your work-

piece, loosen the M8 Knob

located in the arced slot

and rotate the triangle body until the pointer indicates the

angle of your choosing. Tighten the M8 Knob and go about

marking or scribing your workpiece.

Variable Angle Fence for

MFT-Style Worktop

First, configure the MTR-X

with its protractor assem-

bly installed. Insert the

triangle into your MFT-style

worktop at the desired loca-

tion. Set the angle using the

M8 Knobs on the protrac-

tor, abut your workpiece to the long edge of the triangle,

and proceed to make your cut.

Variable Angle Guide Rail

Square

First, configure the MTR-X

with its protractor assem-

bly installed. Attach the

Guide Rail connector to the

triangle and compatible

guide rail. Set the angle

using the M8 Knobs on the

protractor assembly. With both Triangle Dogs touching the

front edge of your panel, make the cut with your tracksaw.

Square MFT/3 Guide Rail to Fence

Not sure if your MFT/3 guide

rail is positioned at a perfect

90 degree angle from the

fence? Use the triangle to

quickly confirm squareness.

Install the longer 25mm

Edge Index Pins on one face

of the triangle and position

that side against the elevat-

ed guide rail, with the other

edge pushed tight against

the MFT/3 fence.

Quick 45° or 90° Cuts on

MFT-Style Worktop

Skip the setup fuss and get

to cutting fast. Drop two

Triangle Dogs into your

MFT-style worktop and then

place the triangle on top of

the dogs. Be sure the “dou-

ble groove” feature of the

dogs face upward.

Adjust Your Miter Gauge to a Perfect 45 or 90 Degrees

Confirm your miter gauge

is at a perfect 45 degrees to

the table saw blade by first

aligning the hypotenuse

edge of the triangle with

your table saw blade. Ensure

the triangle spans the entire

length of the blade, in-

cluding the carbide cutters

which are typically wider

than the core. Loosen your

miter gauge angle adjustment and slide it into your miter

channel, up to the edge of the triangle as shown in the

picture above. To calibrate your miter gauge at a perfect 90

degrees to your table saw blade, follow the same procedure

but use the two shorter ends of the triangle.

Square a Cabinet Interior

Attach the Clamping Angles

using the included four M6

Screws to the perpendicular

sides of the triangle. Place

the triangle into the corner

of your casework or drawer,

and secure with clamps to

pull the assembly square

during dry-fit or glue-up.