Table of Contents

Premise .......................................................................... 3

Introduction..................................................................... 4

Symbols.......................................................................... 5

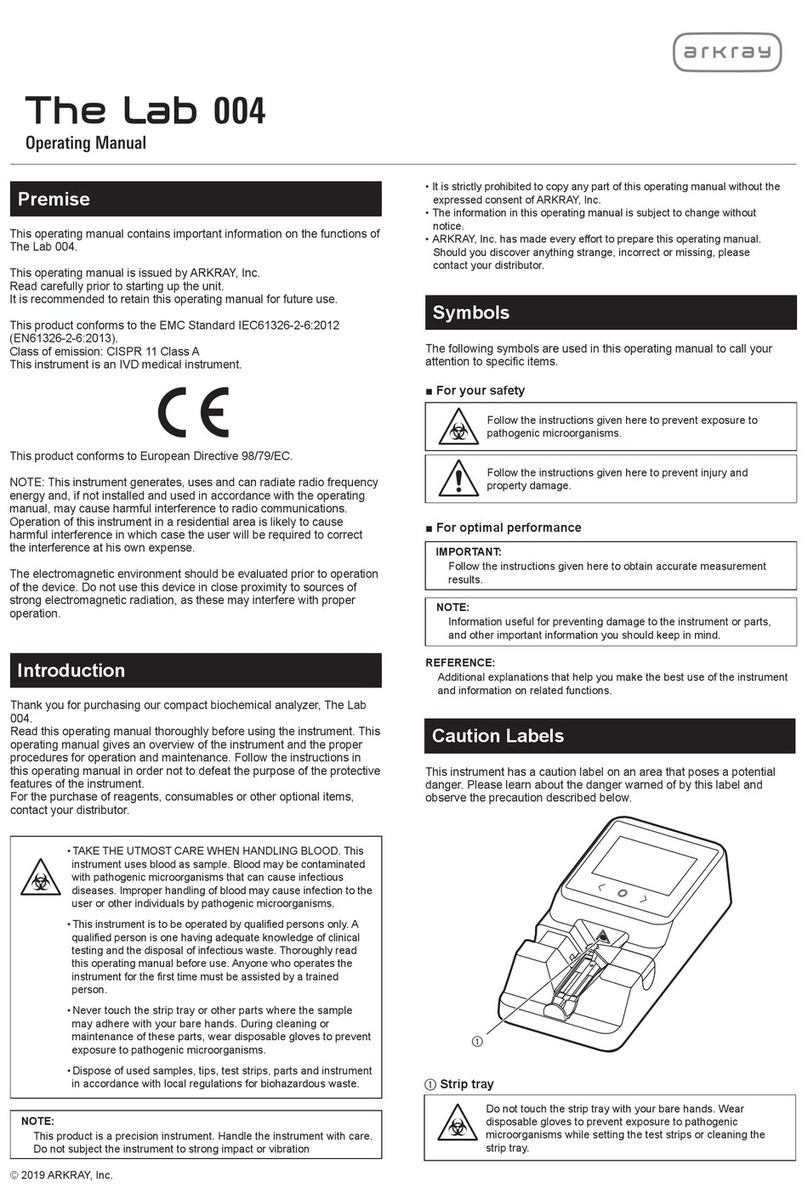

Caution Labels................................................................ 6

Table of Contents ......................................................... 10

Chapter 1 Before Use

1.1 Outline of the AX-4030 ....................................... 1-2

1.1.1 What You Can Do with the AX-4030................ 1-2

1.1.2 Features ........................................................... 1-3

1.1.3 Specifications .................................................. 1-5

1.1.4 Measurement Principle .................................... 1-6

1.1.5 Rank Table..................................................... 1-11

1.2 Unpacking ......................................................... 1-13

1.2.1 Instrument ...................................................... 1-13

1.2.2 Sampler.......................................................... 1-13

1.2.3 Accessories.................................................... 1-14

1.2.4 Accessory Case ............................................. 1-15

1.3 Components ...................................................... 1-16

1.3.1 Front View ...................................................... 1-16

1.3.2 Rear View....................................................... 1-17

1.4 Installation......................................................... 1-18

1.4.1 Precautions in Instrument Installation ............ 1-18

1.4.2 Unlocking the Instrument ............................... 1-20

1.4.3 Attaching the Sampler.................................... 1-23

1.4.4 Installing the Washing Solution Bottle............ 1-26

1.4.5 Installing the Drain Bottle ............................... 1-28

1.4.6 Installing the Waste Box................................. 1-29

1.4.7 Connecting the Power Cord and

External Devices ............................................ 1-30

1.5 Starting Up ........................................................ 1-31

1.5.1 Turning On the Power for the First Time........ 1-31

1.5.2 Setting up the Printer and System Clock ....... 1-33

1.5.3 Turning Off the Power .................................... 1-34

1.6 Relocation ......................................................... 1-35

1.6.1 Precautions in Instrument Relocation ............ 1-35

1.6.2 Checking for Leftover Test Strips................... 1-35

1.6.3 Discharging the Washing Solution ................. 1-36

1.6.4 Unplugging the Power Cord ........................... 1-36

1.6.5 Disconnecting the Tubes,

Sensor Code, and Cables .............................. 1-37

1.6.6 Detaching the Sampler................................... 1-38

1.6.7 Relocating the Instrument .............................. 1-39

1.7 Basic Operations .............................................. 1-40

1.7.1 Components on the Operator Panel .............. 1-40

1.7.2 Screen Configuration ..................................... 1-41

1.7.3 Menu Operations and Examples.................... 1-42

Chapter 2 Measurement

2.1 Before Making Measurements........................... 2-2

2.1.1 Flowchart of Operational Procedure ................ 2-2

2.1.2 Measurement and Calibration .......................... 2-3

2.1.3 Measurement Terminology .............................. 2-4

2.1.4 Sample Containers and Sample Racks ........... 2-7

2.2 Measurement Precautions ................................. 2-9

2.2.1 Handling the Instrument ................................... 2-9

2.2.2 Handling Samples .......................................... 2-10

2.2.3 Handling Test Strips....................................... 2-11

2.3 Preparation for Measurement.......................... 2-12

2.3.1 Checking Wastes and Consumables ............. 2-12

2.3.2 Turning on the Power..................................... 2-14

2.3.3 Loading Test Strips into the Feeders ............. 2-16

2.3.4 Assigning the Type of Test Strips

to the Item Racks ........................................... 2-19

2.3.5 Preparing Samples......................................... 2-21

2.4 Measurement Operations ................................ 2-23

2.4.1 Normal Measurement:

Measuring Samples Continuously.................. 2-23

2.4.2 Port STAT Measurement:

Measuring a Higher Priority Sample .............. 2-27

2.4.3 Rack STAT Measurement:

Measuring Higher Priority Samples................ 2-31

2.5 S.G. Calibration................................................. 2-34

2.5.1 Preparing S.G. Standard Solutions ................ 2-34

2.5.2 Starting S.G. Calibration ................................ 2-36

2.6 Control Measurement....................................... 2-38

2.7 Check Measurement......................................... 2-43

2.8 Displayed and Printed Reports ....................... 2-49

2.8.1 Displayed Results Report............................... 2-49

2.8.2 Printed Results Report ................................... 2-50

2.8.3 Abnormal Results List .................................... 2-54