7

Set up the sensor. Choose an optimum sensor and fix in the main body

with one-touch connector.

1

Turnonpower. POWERbutton−PUSH No

No

No 00→No 01

No 01→No 02

No 00→No 02

2

Input No. by numerical keypad or

select button.

“SELECT”button −PUSH

【Number is forwarded sequentalty every time

“SELECT”button is pressed. 00→01→・ ・→38→39

00→01→02→In addition, you can jump to any

designated number by pressing a number with

numeric key. 】

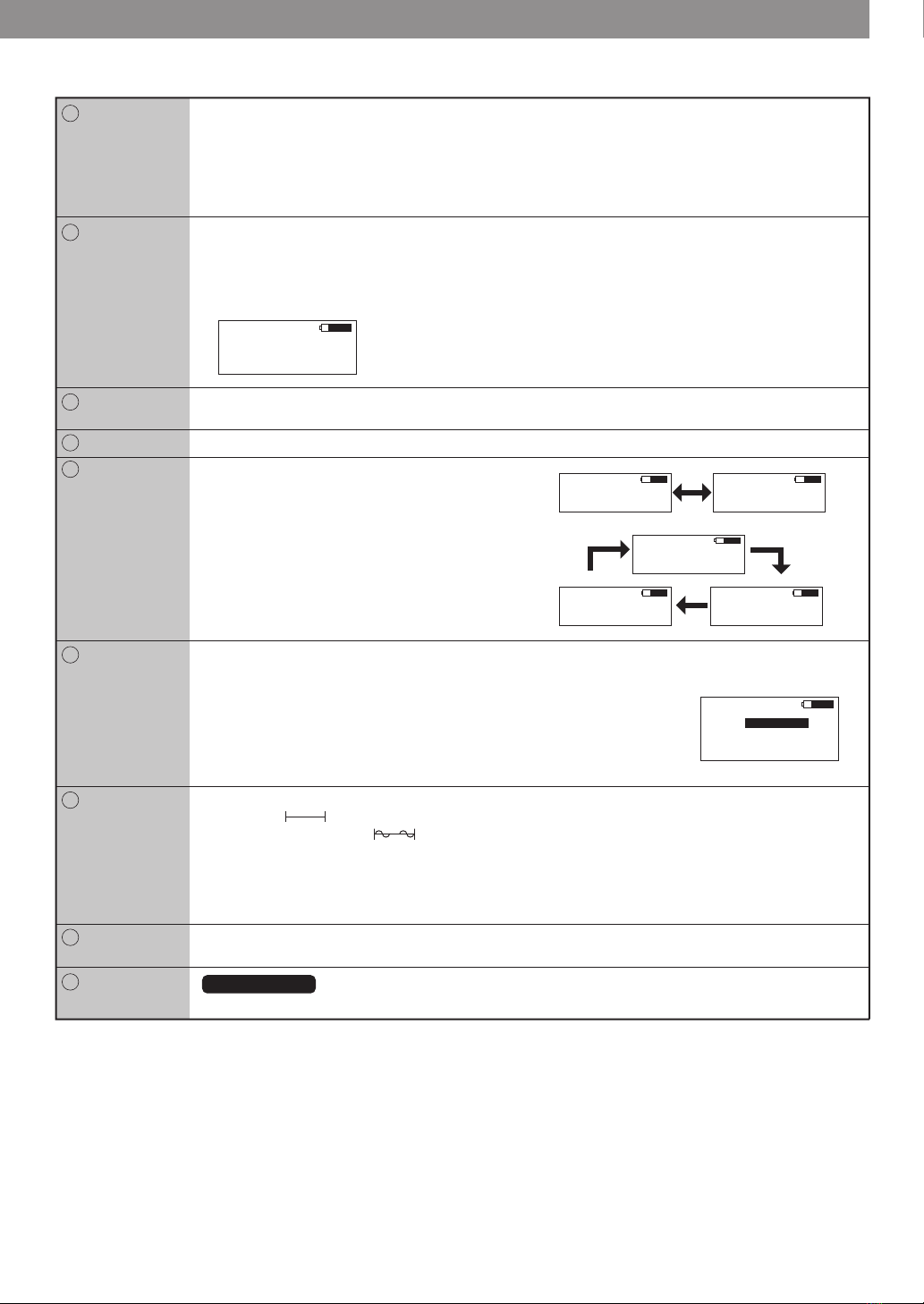

Selecting procedure

“SELECT”button −PUSH(1st time)

“SELECT”button −PUSH(2nd time)

electing procedure

“2”button −PUSH

When “SELECT” button is pressed during the

following procedure (during display of unit mass,

belt width, span length input, and measured value),

the number being chosen is displayed.

3

EX: Select from 00 to No.02

Case of inputting a unit mass

manually.

Caseofinputtingtheunitmass

frombelttype.

EX:SelectP5M.

[See page 9 for input data.]

[See page 9 for input date.]

EX: Put 2.5g/mm wide x meter

long

Input the belt width.

EX: Put 25mm.

[See page 9 for input data.]

“MASS”button −PUSH

[Input the unit mass(g/mm W x m L) in the order of

blinking position on display screen by use of

numeric key. If you input wrong number, press

"MASS" button again to return the cursor to the

first.]

“0”button −PUSH

“0”button −PUSH

“2”button −PUSH

“5”button −PUSH

●"MASS"button−PUSH(holdingdownmore

thanonesecond)Belttypeisshownonscreenby

pressingMASSbuttonmorethanonesecond.

ByusingUPorDOWNbuttontoselectthe

belttype.

●"DOWN"button−PUSHPlacehighlighted

portiononP5M.

●"MEASURE"−PUSH

PX5Misdisplayedonscreen.

4-1

4-2

“WIDTH”button −PUSH

【Do the same step as the above 4-2. When data

above alIowable capacity is input, the cursor

returns to the first, and input of data is requested

again.】

“0”button −PUSH

“2”button −PUSH

“5”button −PUSH

“0”button −PUSH

5

Input the span length. “SPAN”button −PUSH

【Do the same step as the above 4-1.】

6

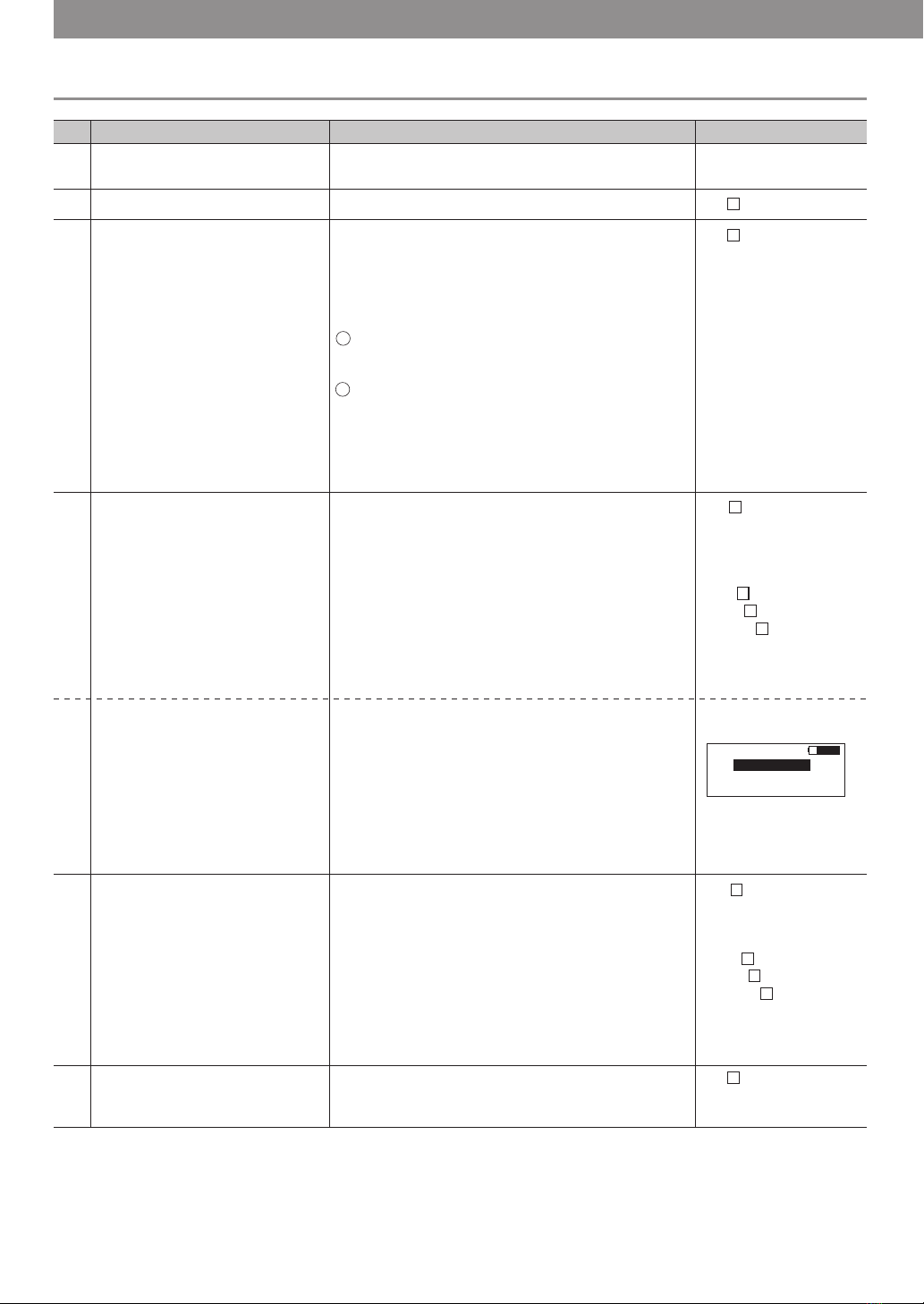

Procedure

Description Operation Display screen

5. Operation procedure of BDTM201

S= □□□mm

『

Allowable input capacity:

0001〜9999mm』

W= □□.□mm/R

『Allowable input capacity:

000.1〜999.9mm』

W=0 □.□mm/R

W=02 .□mm/R

W=025. mm/R

W=025.0mm/R

M= □□.□g/m

『Allowable input capacity:

0.1〜999.9g/mm×m』

M=0 □.□g/m

M=00 .□g/m

M=002. g/m

M=002.5g/m

Shows frequency after

measurement of tension.

"Hz" button −PUSH

[Shows frequency corresponding to the measured

tension.

When "Hz" button is pressed once again, the display

returns to tension mode.]

8-2

S No 02

PX 5M 4.1

PX 3M 2.0

01

03

02

PX 2M 1.4

Shows tension. "Hz" button −PUSH

[Shows frequency corresponding to the measured

tension.

*When "Hz" button is pressed once again, the

display returns to tension mode.]

8-1

Start measurement. Get sensor in central span of the measure object

without touching it.

"MEASURE" button −PUSH: LED(green)

blinks, shows .

To vibrate the wire, flip the belt span with a

finger etc.: shows .

The following measurement is performed by the

sensor receiving sound without use of measure

button from the second time.

Since measurement is started by the senor

receiving sound, it is started as well even by a

noise if it has a relatively stable sound pressure.

Result is shown as well as beep sound emitted

and LED(green)turns on in 0.2 second after

reception of belt vibration sound.

[After the second

measurement, please

notice that the screen

shows the data

previously measured.

And you hear the beep,

the new data will be

displayed on the

screen.]

71

2

3

1

2