ZERO:

0-10 CENTIBARS:

10-20 CENTIBARS:

20-40 CENTIBARS:

40-60 CENTIBARS:

60-80 CENTIBARS:

CENTIBARS OF SOIL

SUCTION

SOILMOISTURE EQUIPMENT CORP

Santa Barbara, CA USA

90

80

70 60 50 40

30

20

10

0

DRY

WET

100

D

O

N

O

T

F

R

E

E

Z

E

SOILMOISTURE

CENTIBARS OF SOIL

SUCTION

SOILMOISTURE EQUIPMENT CORP

Santa Barbara, CA USA

90

80

70 60 50 40

30

20

DRY

WET

100

10

0

D

O

N

O

T

F

R

E

E

Z

E

SOILMOISTURE

CENTIBARS OF SOIL

SUCTION

SOILMOISTURE EQUIPMENT CORP

Santa Barbara, CA USA

90

80

70 60 50 40

30

20

DRY

WET

100

10

0

D

O

N

O

T

F

R

E

E

Z

E

SOILMOISTURE

CENTIBARS OF SOIL

SUCTION

SOILMOISTURE EQUIPMENT CORP

Santa Barbara, CA USA

90

80

70 60 50 40

30

20

DRY

WET

100

10

0

D

O

N

O

T

F

R

E

E

Z

E

SOILMOISTURE

CENTIBARS OF SOIL

SUCTION

SOILMOISTURE EQUIPMENT CORP

Santa Barbara, CA USA

90

80

70 60 50 40

30

20

DRY

WET

100

10

0

D

O

N

O

T

F

R

E

E

Z

E

SOILMOISTURE

CENTIBARS OF SOIL

SUCTION

SOILMOISTURE EQUIPMENT CORP

Santa Barbara, CA USA

90

80

70 60 50 40

30

20

DRY

WET

100

10

0

D

O

N

O

T

F

R

E

E

Z

E

SOILMOISTURE

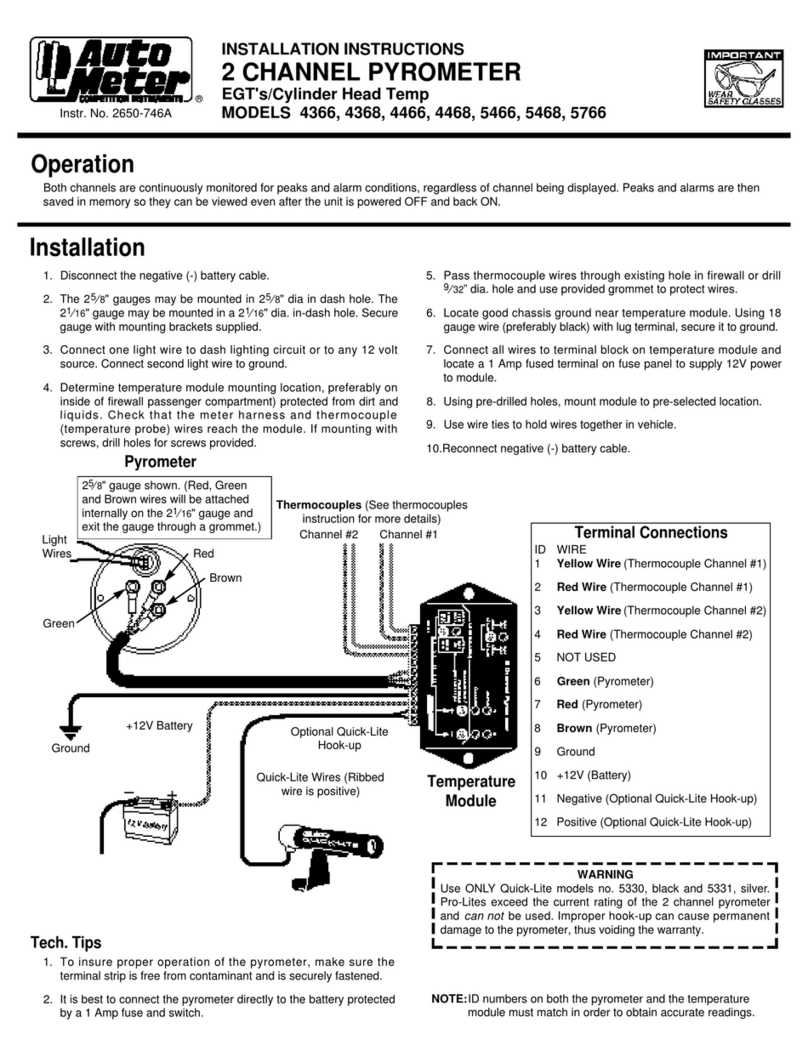

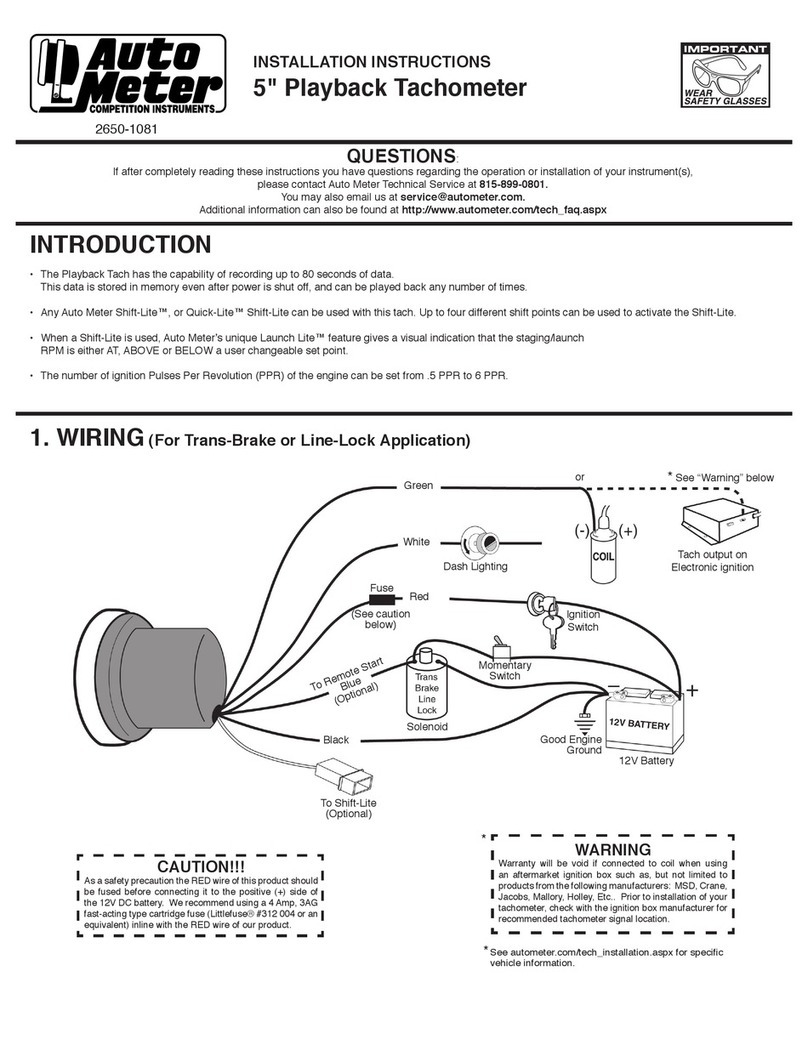

A gauge reading of zero means the

surrounding soil is completely saturated

with water, regardless of the type of soil.

Zero readings can be expected after a

heavy rain or deep irrigation. If the zero

reading persists after a long

period of time, there will be oxygen

starvation to plant roots and develop-

ment of diseases. A persistent zero

reading after irrigation indicates poor

drainage conditions which should be

investigated and corrected.

Gauge readings in the range of 0-10cb

indicated a surplus of water for plant

growth. Water held by the soil in this

range drains off within a few days.

Persistent readings in this range

indicate poor drainage conditions

which should be corrected to obtain

healthy plant growth.

Gauge readings in the range of 10-20cb

indicate that there is ample moisture

and also air in the soil for healthy plant

growth in all types of soils. This range is

often referred to as the “field capacity”

range for soils, which means that the

soil has reached its “capacity” and

cannot hold anymore water for future

plant growth. When soils are at “field

capacity”, any additional water that is

added drains out of the root zone within

a day or two—before it can be used by

the growing plant. If irrigation has been

in process, it should be stopped when

gauge drops to this level, since any

further additional water will be quickly

drained from the root zone and wasted,

carrying with it valuable fertilizer.

Available moisture and aeration good

for plant growth.

HEAVY CLAY SOILS: No irrigation

required.

MEDIUM TEXTURED SOILS: No

irrigation required.

SANDY SOILS: Irrigation started for

coarser sandy soils in the 20-30 cb

range. For finer sandy soils in the

30-40 cb range.

Available moisture and aeration are

good for plant growth in finer textured

soils.

HEAVY CLAY SOILS: No irrigation

required.

MEDIUM TEXTURED SOILS: Irriga-

tion started in this range. The finer the

texture the higher the reading before

start of irrigation.

SANDY SOILS: Too dry. Hot windy

conditions can force soil suction to

high reading quickly and damage

plants.

Readily available moisture scarce,

except in heavy clay soils.

HEAVY CLAY SOILS: Start of irriga-

tion desirable as soil suction values

reach 70-80 cb.

MEDIUM TEXTURED SOILS: Too

dry. Hot, windy conditions can force

soil suction to high reading quickly

and damage plants.

SANDY SOILS: Too dry. Damage to

plants will occur before irrigation can

be applied.