2/14

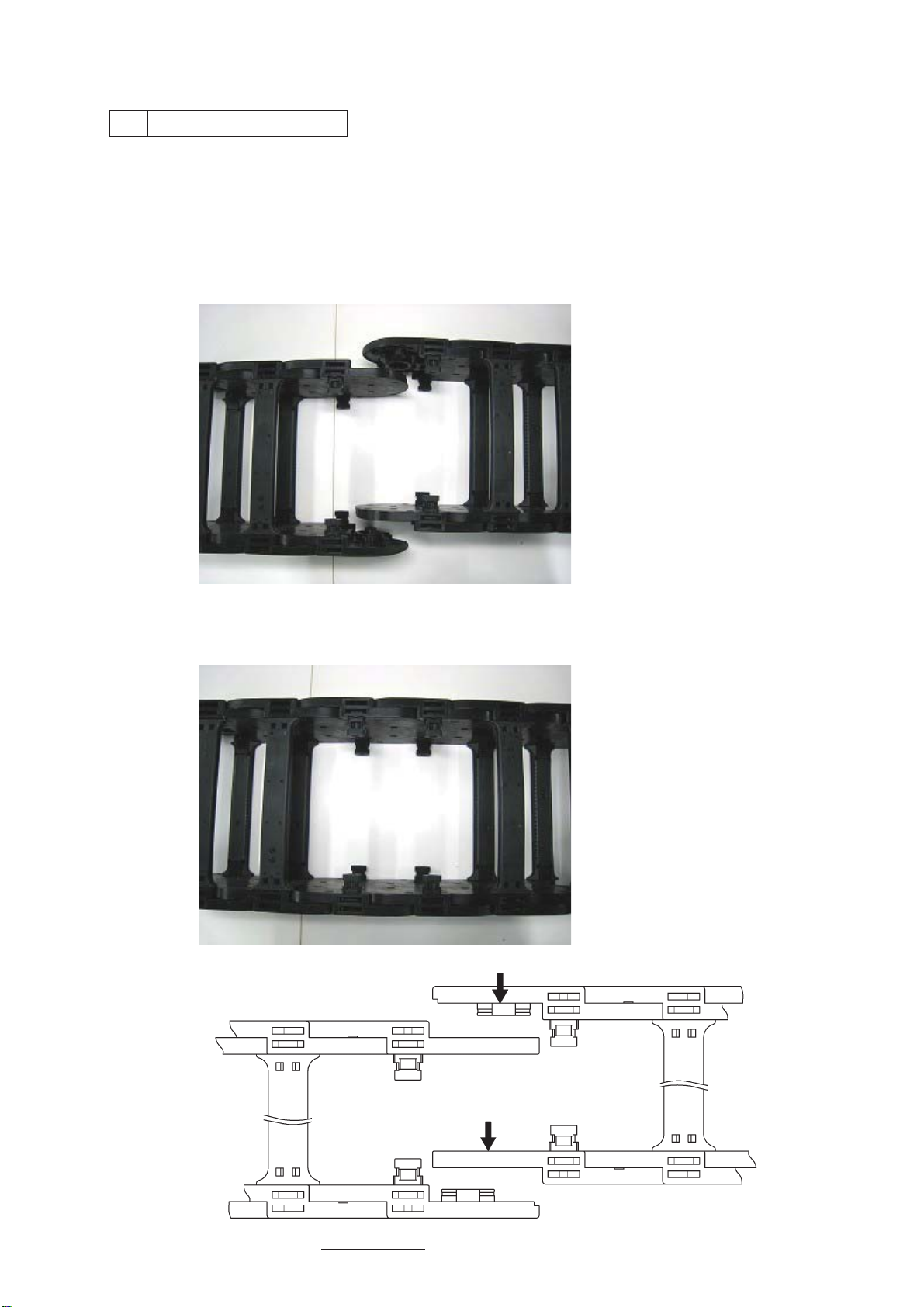

2 Before Assembly

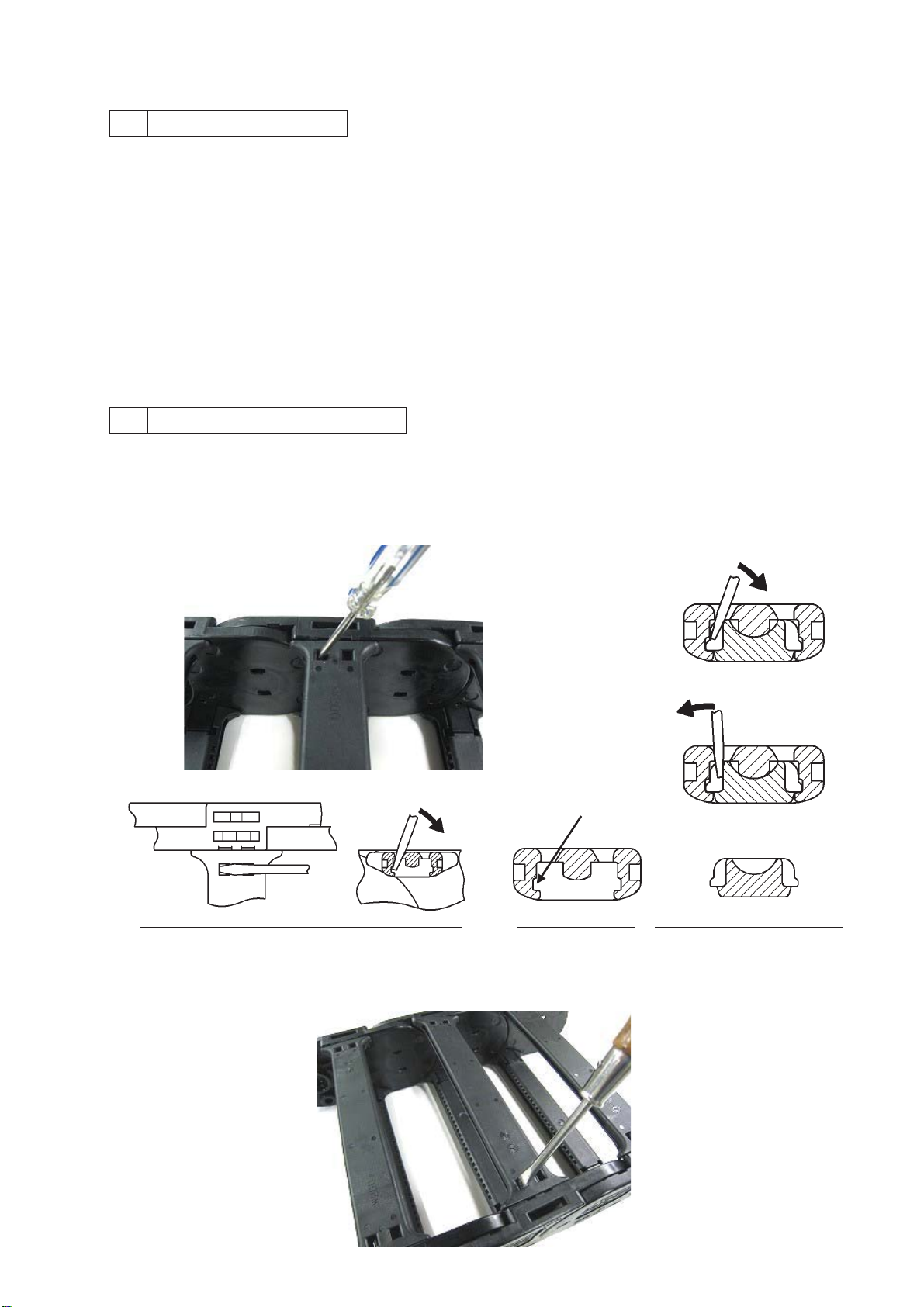

1) Use only a flat-head screwdriver with a 4.5mm head and a plastic hammer.

A screwdriver with a larger head will not fit into the release hole and can damage parts.

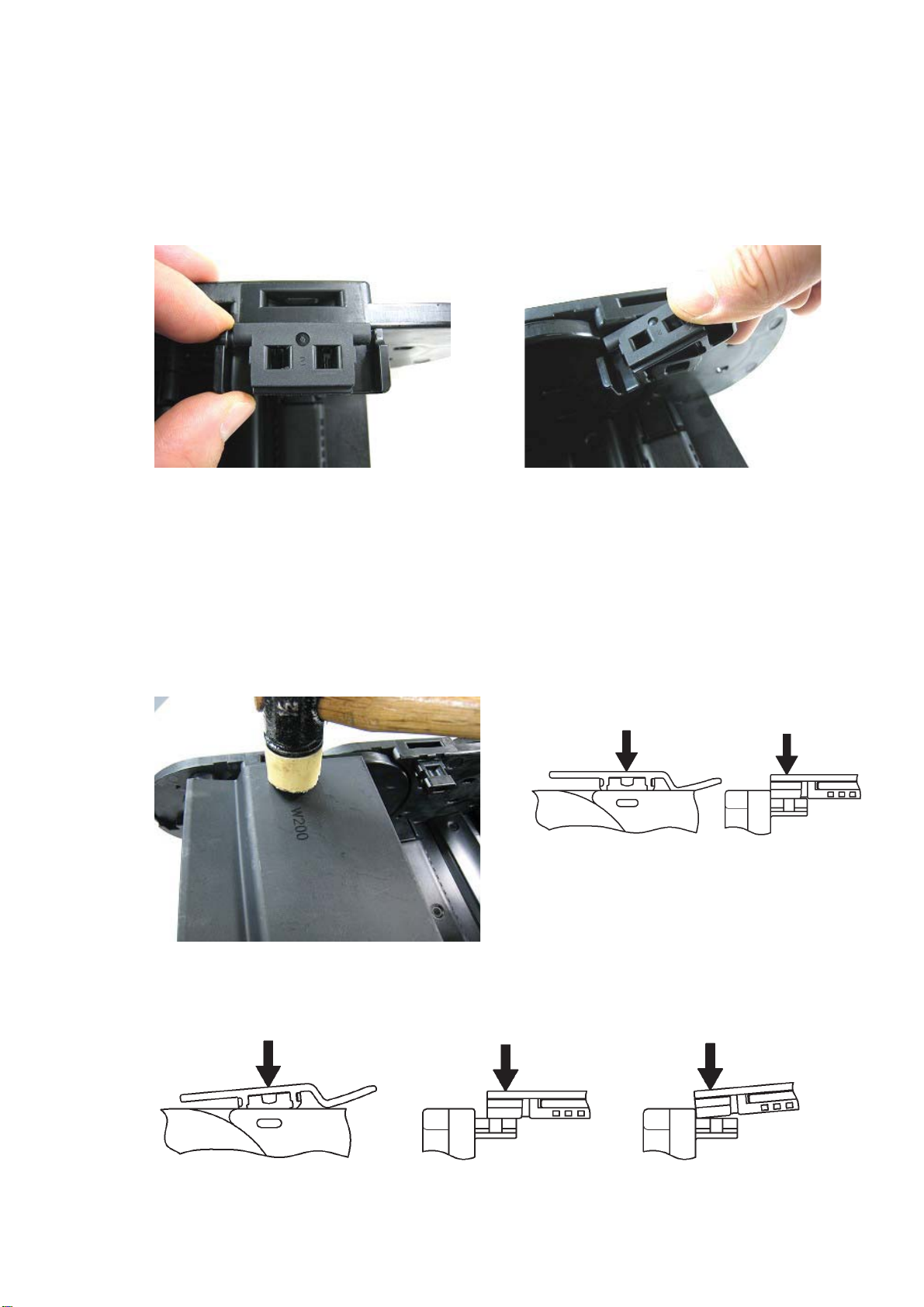

2) This product can be easily assembled and disassembled. If parts are difficult to insert they may be misaligned.

Do not pound in. Check positioning and realign.

3) There is no need to tap the screwdriver handle with a hammer. Doing so may damage parts.

4) Wear gloves, safety glasses, safety shoes, and other protective gear as appropriate when working.

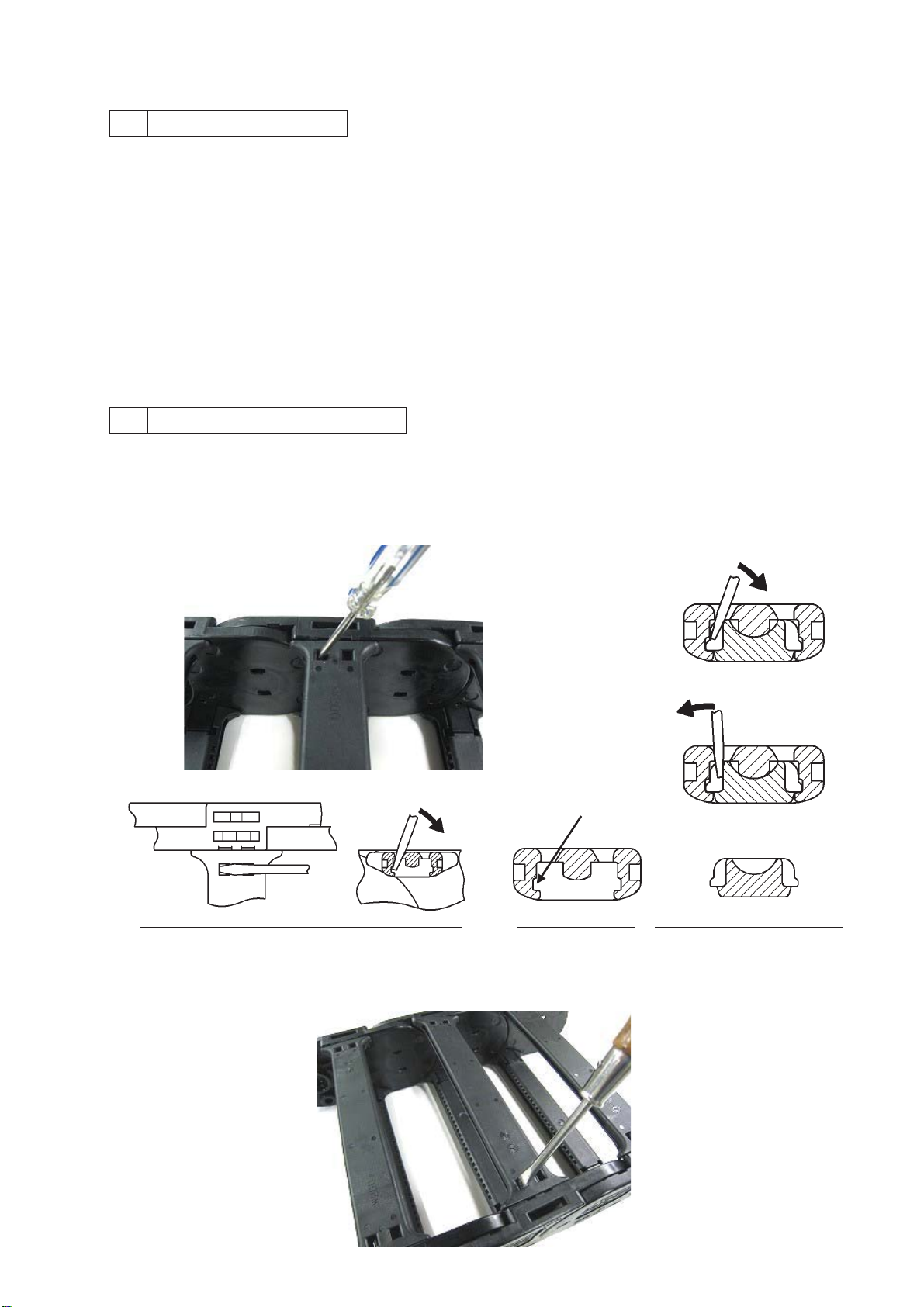

3 Arm Types and Removal

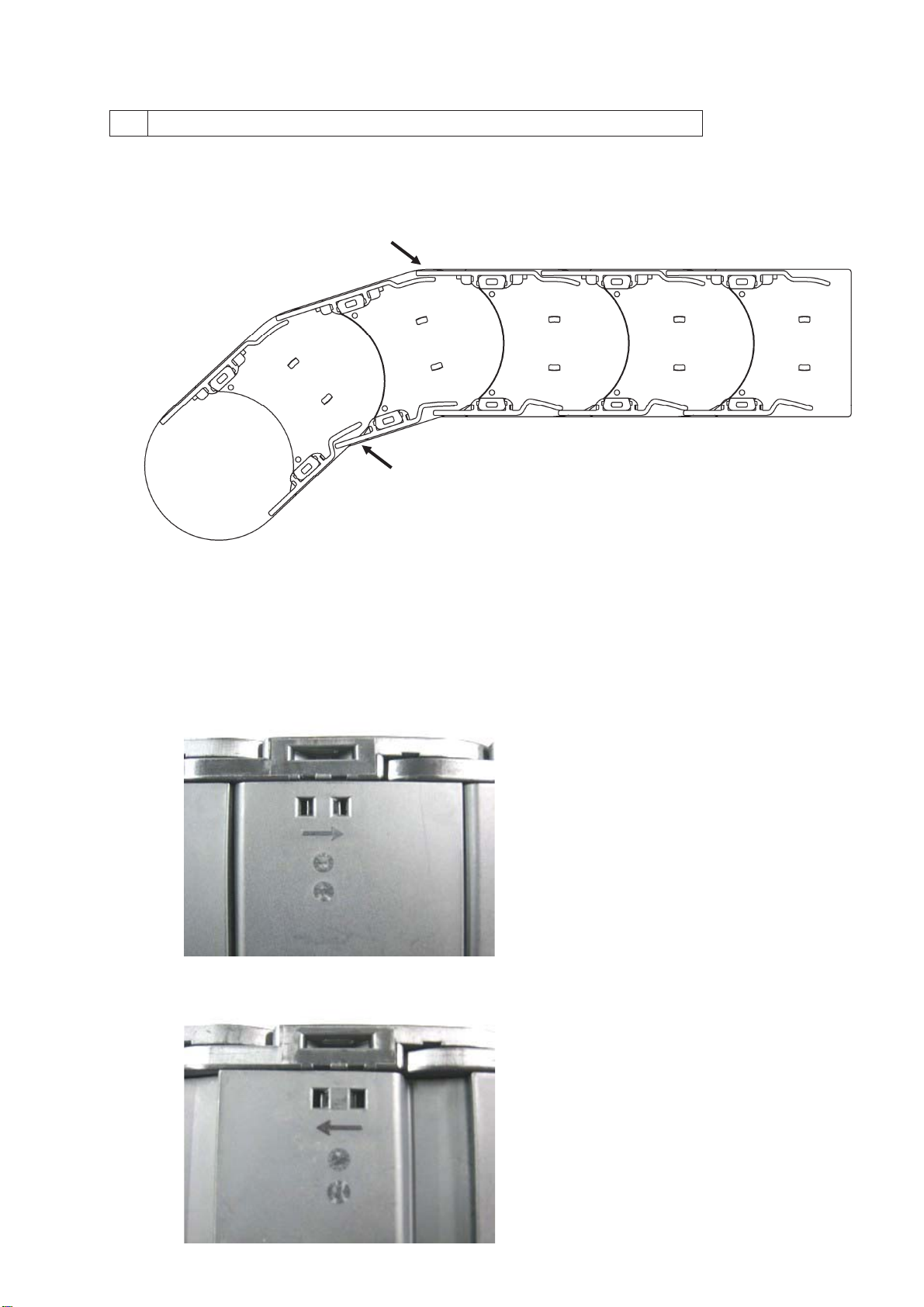

*All TKP91 (open type) arms are interchangeable (Caution!)

1) Hold down the arm with your hand and insert a Cross-section of arm and link

screwdriver about 7mm into the release hole and twist Undo the hook as shown below.

as shown in the diagram

㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷䂾

Correct

㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷 ×

Bad

㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷㩷

Hook

㩷㩷㩷Upper and cross-sectional view (link side omitted)㩷㩷㩷㩷 Arm cross-section㩷㩷Cross-section of link fastener

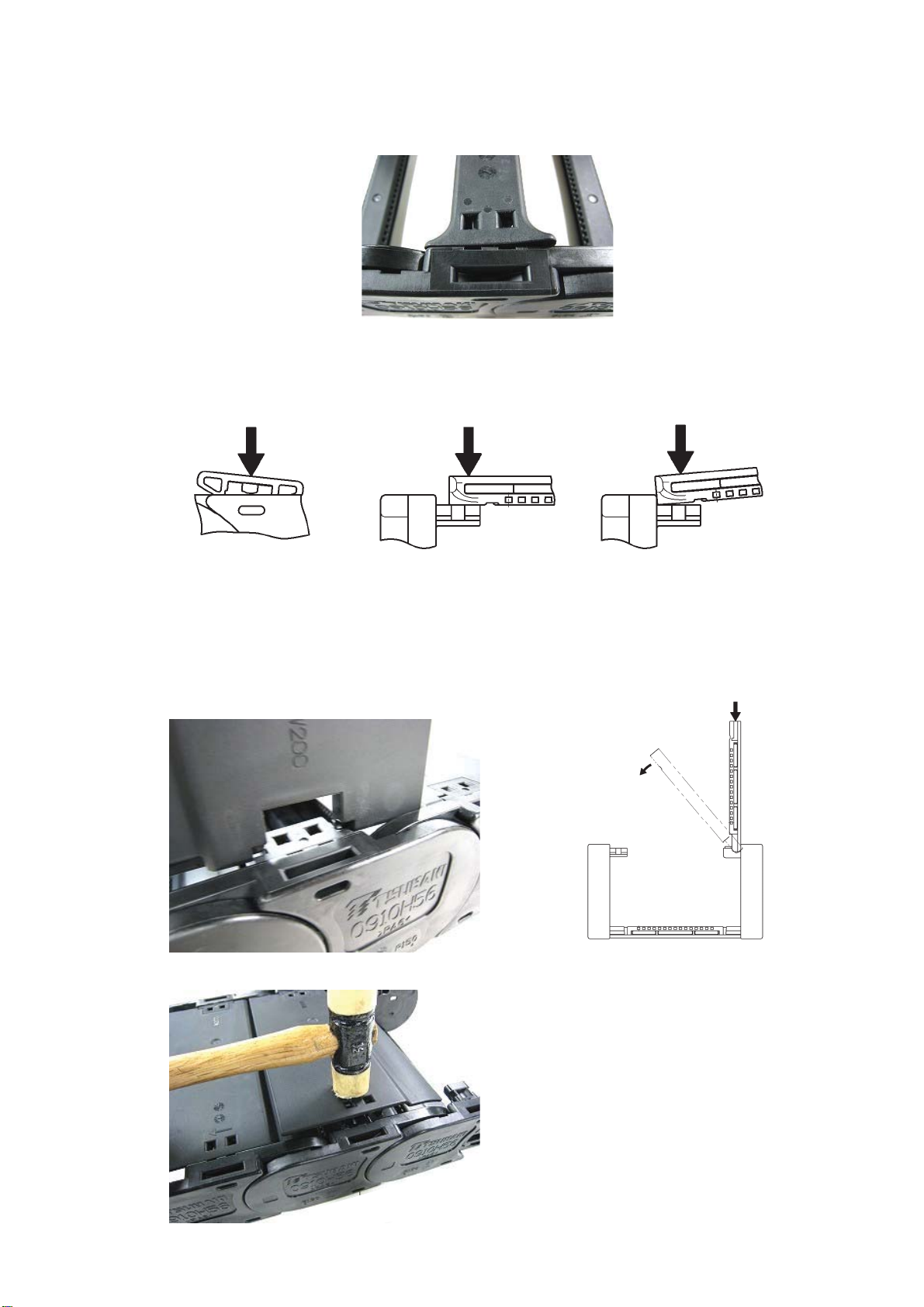

2) Once you have undone the hook and one side of the arm has lifted, undo the hook on the opposite side and

twist and lift up to remove arm.