TTC FIREBERD 6000 User manual

-~

ARTISAN

®

~I

TECHNOLOGY

GROUP

Your definitive source

for

quality

pre-owned

equipment.

Artisan Technology

Group

Full-service,

independent

repair

center

with

experienced

engineers

and

technicians

on staff.

We

buy

your

excess,

underutilized,

and

idle

equipment

along

with

credit

for

buybacks

and

trade-ins

.

Custom

engineering

so

your

equipment

works

exactly as

you

specify.

•

Critical

and

expedited

services

•

Leasing

/

Rentals/

Demos

• In

stock/

Ready-to-ship

•

!TAR-certified

secure

asset

solutions

Expert

team

ITrust

guarantee

I

100%

satisfaction

All

tr

ademarks,

br

a

nd

names, a

nd

br

a

nd

s a

pp

earing here

in

are

th

e property of

th

e

ir

r

es

pecti

ve

ow

ner

s.

Find the VIAVI Solutions / JDSU / TTC 40202 at our website: Click HERE

Quick

Cards

TbeseQuick

Cuds

bave

been

asembkd

to

be&

usem

emilyperfm

basic

testfunctim.

Tbe

Quick

Cuds

are

ah

emue

toolr

to

fanuiarize

new

users

wltb tbe

PIREBERD

6000

test

set.

TouretbeQuickCmdc

I.

Select

tbedesitpdqt@aatim

fmn,

the Tableof Contents.

2.

Refi

totbe

appyWiate

setup

card

to cmp@re the

FUU?BERD

60W.

3.

Ifadditiond inzm

is

needed,

refer to the

PLRpBBRD

MXM

User's

Guide

I

Table

of Contents

Codpation

Wups

Full

TI In-SerivceMonitoring

Tlm1Out-of-SeniceBERT

Tlm1-Voice

and

Signaling

ANSI T1.403

PRMs

with the

41440A

Interface

2M In-Service Monitoring

2WNx64 Out-of-Senice

BERT

Wf-Service V.35 Testing

DSOA

Out-of-SeniceTesting

Out-of-Senice RS232 Testing

Frame &lay Out-of-Service

Frame Relay In-Service

Frame Relay

IP

Ping

AppppUCati0~

Frame Relay In-Senice Monitoring

Frame Relay

local

Conndvity

Test

(link

Management Verification)

Frame Relay End-to-End

Conneclivity

Tesl

FaneRelay

IP

Ping Test

Full.TI

T1.lTI.BERT

Tl.IT1.Voice

ANSI.Tl

2M.h-Senice

2M.Out-Senice

V.35

DSOA

I8232

Fr.Relay.0~1-Service

Fr.Re4ay.h-Service

Fr.Relay.Ping

TTC

Technical

Support

1-800-638-2049

FB6000-TOCXard1.1/3.97

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Full

TI

In-Service

oni it or in^

~be~ngprocadwe

outlines

bow

townnecttbe

PLRBB~RD

60W

wii%

b

414&

intm$ke

to

tbe

netuwk

in

wdR.tops&m

a

Pull

TI

In-ServlceMonitm'ng

test.

&w&reud

tbe

enrireprocedum

BEFORRstarting.

.

WB-SetuptkP~60W~connectingtotbe~.

.

@

conti@mng

tbe

appopiak

soflby,

you

dscmU

tbrougbtbe menu untilyou

)8a~byarr

desirsdsSmng.

A

(up-amnu

by)

is

dtoreturn to tbepeviousmenu sektlon.

.

use

ise

tliesophey

to

snoll

tbrough

tk

optionsunrilyou reach

~~

(LBD

beside

it

is

illuminated).

Thfdbw

tte

steps

bebw:

I

PaH

1

-

lntedace

Setup

Tlrn1

CONFIG

WAm

CODE

m

MORE

RESULT

m1

A

MODE

FULLT1

ENTER

ANALYSIS

MODE

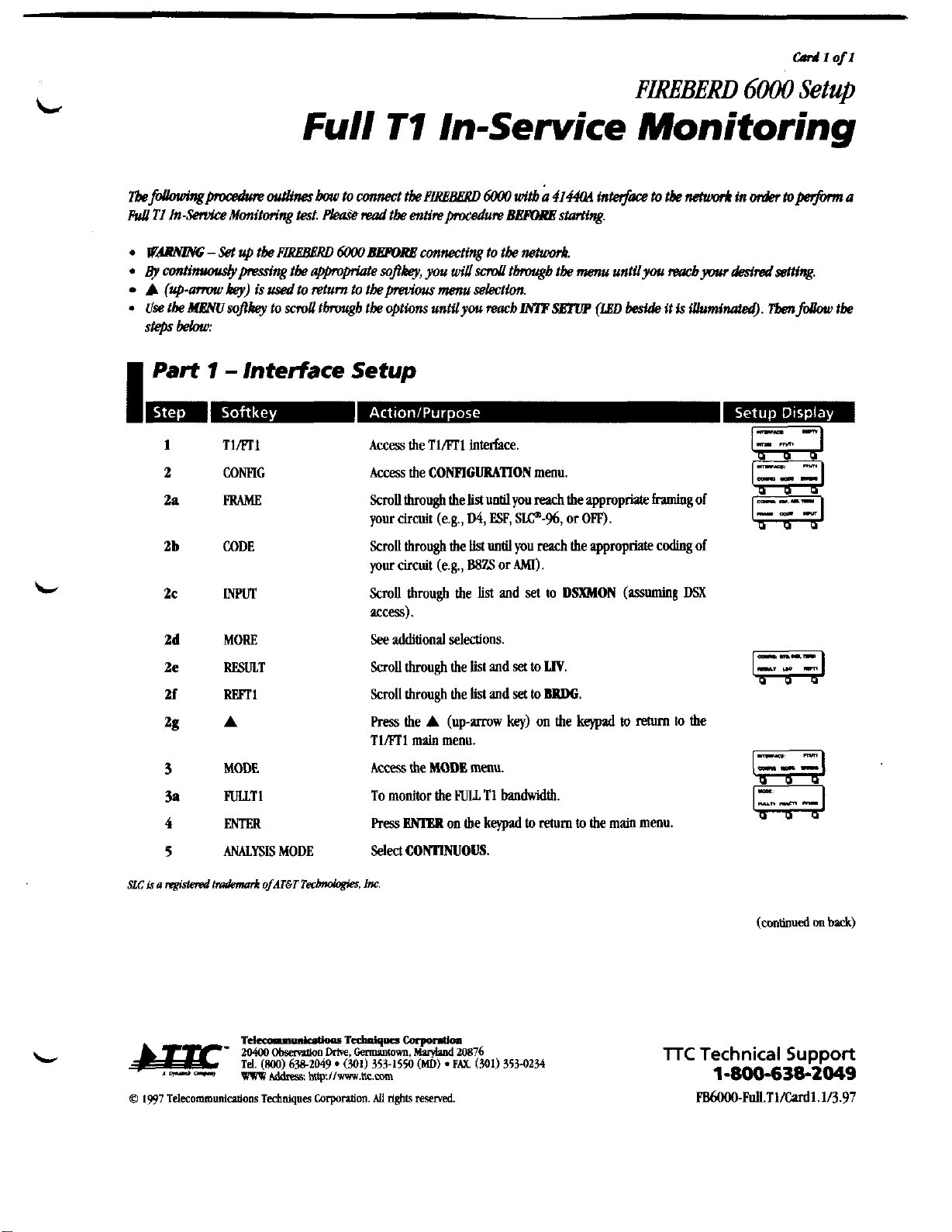

Access the Tl/ETIinterface.

Access the

CONFIGURATION

menu.

Scrollthrough the

list

untilyou

reach

the appropriateframingof

your circuit (e.g.,

D4,

ESP,

SLP-%,

or

OFF).

Scrollthrough the

List

until you

reach

the appropriatecodingof

your circuit (e.g.,

B8ZS

or

AM).

Scroll through the list

and

set

to

DSXMON

(assuming

DSX

access).

See

additionalselections.

Scrollthrough the

list

and

set

to

LIY.

Scrollthrough the

lisl

and

set

to

BRDG.

Press the

A

(up-mw

key)

on the

keypad

to

return

to

the

TIml

main

menu.

Access

the

MODE

menu.

To monitor the

FULL

T1

bandwidth.

Press

ENlER

on the

keypad

to

rehun

to

the main menu.

Select

comous.

(contmued

rm

back)

TTC

Technical

Support

1-800-638-2049

pg6000Full.TI/Cudl.l/3.97

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Part

2

-

Performing the Test

,

1

Press

RESTART

to

clear

alarms

and

begin

the test. Venfy

that:

A.

mREBERD

6000's

PAITERN

SYNC

LF.D

is illuminated

(indicating

a

signal

is

present).

B.

F'IREBERD 6000's

PRM

SYNC

LED

isilluminated

(if

PRM

SYNC

is

not illuminated,go

back

to

Step

2a

and

select

the appropriateframeformat).

Table

I

lists

intportantMYLSIS

RBSm

tbal

sboull

be

cbecw.

I

Table

7

-

Analysis Results

T-CARRIBR

BWs

FRA

ERR

CRC

ERR

FRA

LOSS

BIT

SLIP

SIGNAL

+LVL

dB

-LVL

dB

PP

LVL

v

RCV

FREQ

Bipolar Violalions

Frame Emors

CRC

Ermn

(ESF

framing

only)

Frame

Loss

Bit Slips (applicableonly

with

a REFCl)

Positive Receive Signal

level

Negative Receive Signal

Level

Peak-to-PeakReceive Signal

level

(volts)

Receive Frequenrj

I

Table

2

-

Interface Status LEDs

CODE

ALM

1

ALM

2

Illuminates

when

B8ZS

cading

is

being

received.

Illuminates

when

a

Yellow

Alarm

isdetected.

Illuminates

when

an

Excess

Zeros

Alarm

is

detected.

0

1997

Teleeommunicltions

Technique

Corpontion.

All

rights

mewed.

lTC

Technical

Support

d

1-800-638-2049

FB6000Full.Tl/Cardl.lI3.97

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

TIIFTI

Out-of-Sewice

BERT

WAWYZm;

-

Set

up

tbe

PIRh'BBRD

MXM

BBPORP

connecting

to

tk

nehuork.

By

amtinuouslypresstngtk

appropriate

sofikey, you

dsd

thgb

tk

menu untilyou mbyour

&redsetting.

A

(up-anwu

key)

is

used

to

return to tkpmfusmuselection.

Use tkMENUsofikey to

sd

thgbtkoptwnsuntilyou reacb~~

(LED

&side

it

is

illuminated).

Tbm

folbur

tk

StGpS

belau:

I

Part

1

-

Interface Setup

1

TIAT1 Access the TIAT1 interface.

2

CONFIG

Access the

CONFIGURATION

menu.

2a

FRMlE

ScmU thmughthe list

unUl

you

reach

theappropriateftamingof

your circuit (e.g.,

D4,

ESF,

SIP-%,

or

OR).

2b

CODE

ScmU thmughthe list untilyou

reach

the appropriatecodingof

your circuit (e.g.,

B8ZS

or

MI).

2c

INPUT

Scroll through the list

and

set

to

'TERM

2d

MORE

See additionalselectiom

2e

RESULT ScmU through the list

and

set

to

SII)

2f

LBO

ScmU through the list

and

set

the

Line

Build

Out

to

0

dB.

%

FmT1 Scrollthrough the list

and

set

to

BRDG.

2h

A

Press

the

A

(up-mw

key)

on the

keypad

to

return

to

the

previous menu.

3

ERRINS

Set

to

OW.

3a

A

Press the

A

(up-mw

key)

on the

keypad

to

return

to the

previous menu.

4

MODE

Access the

MODE

menu.

4a

PULLTI Allows you

to

select

and

BWT

the

PULL

T1

bandwidth.

SLC

is

a

@lered

tdmmk

ofAT6T

TecbMbgies,

1m

(continued

on

back)

TTC

Technical

Support

1-800-638-2049

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

I

Part

1

-

Interface Setup

(cont.)

d

m-m

..

..

A

.B

..

ma1

MORE

CLRAU.

56/64

MORE

CH#

W

CH#

DN

lWRT

A

MORE

LOOP

WE

A

RESPND

A

RCVBn'

CH#

W

CH#

DN

A

IDLE

ENTER

ENTER

Select and monitor any selection of lime slots. Tn5con unse-

lected channels

will

be replaced with the idle code entered in

Step

7.

(Repeat

Steps

4b5

and

4b6

for each channel you

wish to 1st.)

See

additionalselections

Clear

all

channelsetupparameten from a previous test.

Choose between

56K

and

64K

bandwidth.

See

additionalselections.

Select the channelsyou wish to drop

Set the selectedchannel to

1WRX.

press

the

A

(up-mwkey) on the keypad

twk%

to return to

the TIAT1main menu.

See

additionalselections

Access the

LOOP

menu.

Select which piece of equipmentyou want

to

loop back. Press

MORE

foradditionalselections

if

needed.

Press

the

A

(up-mow key) on the keypad to return to the

LOOP

menu.

Set the

HREBERD

6000

to

AUTO

(automalically respondsto a

received loop code) or

NONE.

Pressthe

A

(up-mwkey) on the keypad

&ice

to return to

the TILT1

main

menu.

Selecta channel

1-24

to be displayedin the

RCV

BITE

result.

Selectthe channel you wish to monitor.

Press the

A

(up-mow

key)

on the keypad

to

return to the

TliFC1 main menu.

Select an 8-bit binary idle code panern

to

be

inserted in the

inactivechannels.

Press

to set these idle code bits.

Press

on the keypad to returnto the main menu

(continuedon

Card

2)

TTC

Technical

Support

d

1-800-638-2049

FB6000-TI.fll.BERT/Card1.2/3.97

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

TIIFTI

Out-of-Service

BERT

(-t)

I

Part

1

-

Interface Setup

(cont.)

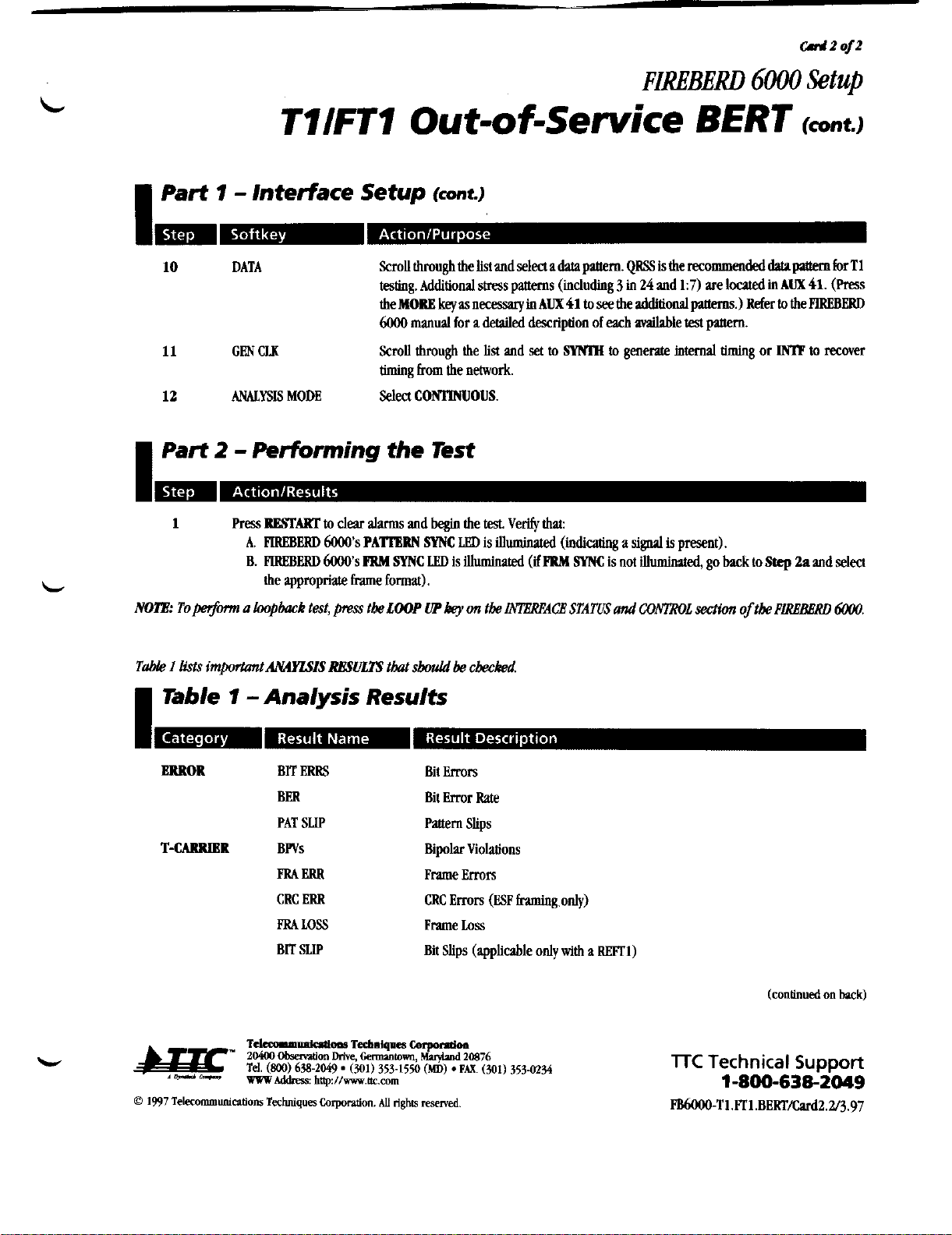

10

DATA

Scrollthrough thelistand

select

a

data

pattern.

QRS

is

the

recommended

data

pvtem

for

Tl

testing.

Additionalstresspanems

(including

3

in

24

and

1:7)

are

located

in

AUX

41.

(Press

the

key

as

necessiy

in

AUX

41

to

s&

the

additid

paaerns.)

Refer

to

the

FlREBERD

6000

manual

for

a

detailed descriptionof

each

4le

test

panem.

11

GEN

CLK

Scroll

though

the list and

set

to

SWIM

to

generate

internal

timing

or

IMP

to

recover

timing

from the network.

12

ANALYSIS

MODE

Select

CONIlNUOUS.

I

Part

2

-

Performing the Test

1

Press

BBSFART

to

dear

llvms

and

begin

the

test.

Verify

that:

A.

FlREBERD

6000's

PATIERN

SYNC

la,

is

illumhated

(indicating

a

signal

is present).

B.

PlREBERD

6000's

FRM

SYNC

IJ!D

is

illuminated

(if

FRM

SYNC

is

not

illuminated,go

back

to

Step

2n

and

select

the appropriateframe format).

MlE:

To+

a

loopback

test,

@press

tbe

LOOP

UP

key

on

tbe

INlBREACE STATIIS

und

CONTROL

section

of

tbe

PLRBBBRD

6000.

Table

I

lists

importuntAU4YLSIS

RBSULTS

that

sW

be

chM.

I

Teble

7

-Analysis Results

ERROR

BIT

ERRS

BER

PAT

SLIP

T-CAIIRIBR

BWs

FRA

ERR

CRC

ERR

FRAm

BIT

SUP

Bit

Errors

Bit Error Rate

Pattern

Slips

BipolarViolations

Frame Errors

CRC

Errors

(ESP

fnmingonly)

Frame

bss

Bit Slips (applicableonly

with

a

Wl)

lTC

Technical

Support

1-800-638-2049

PB6000-Tl.ml.BERT/Card2.2/3.97

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

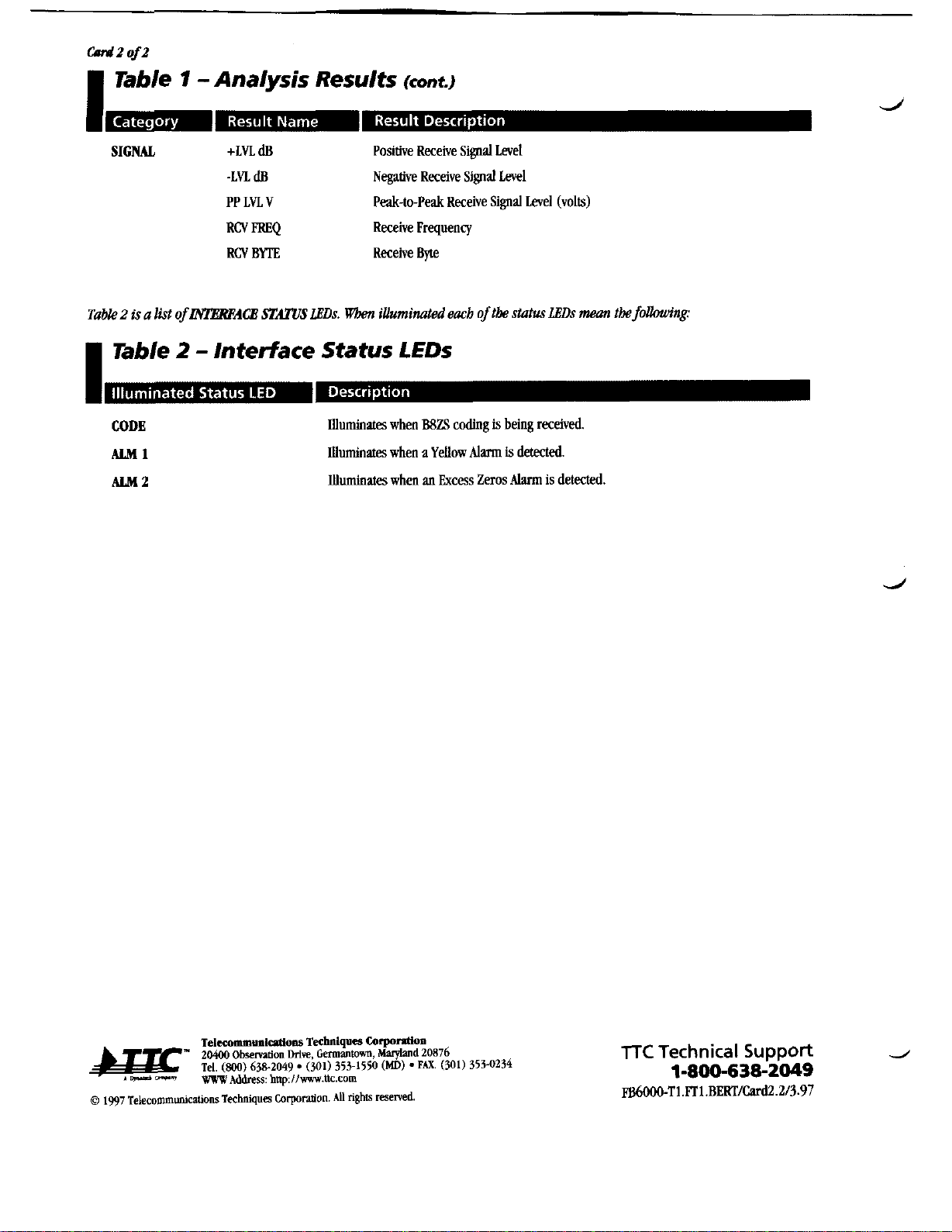

Table

1

-

Analysis Results

(co"~.)

SIGNAL

+LVL

dB

Positive ReceiveSigoalLevel

-LVl.

dB

Nqative

ReceiveSignalLevel

PP

Ln

V

Peak-to-PeakReceiveSignal Level (volts)

RCV

FREQ

ReceiveFrequency

RCV

BlTE

Receive

Bvte

Table2

is

a

list

of

INTEREACE

STATUS,WDs.

Vh

iiUumi~ted

eacb

of

the

status

LEDs

mean

the

fdlowing:

Table

2

-

Interface Status LEDs

CODE

ALM

1

ALM

2

Illuminates

when

B8ZS

coding

is

beingreceived.

Illuminates

when

a

Yellow

Alarm

is

detected.

illuminates

when

an

Excess

Zeros

Alarm

is

deteaed.

TelsommunldoM

Technlqow

Co~ntion

"

20400

Obmtion

Drive,

Germantown,

Mvylvld

20876

Tel.

(800)

638-2049. (301) 353-1550

(MD)

.PAX

(301) 353-0234

lTC

Technical

Support

d

1-800-638-2049

F86000-Tl.kTl.BERF/cud2.2/3.97

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

FIREBEIRD

GOO0

Setup

TllFTl-

Voice

and

Signaling

TkfdbwingptDcadum

wtliw

bow

toconnecttbe

PLRBBeRD

6WO

with

a

4144lM

i&rjface

to

tbe

netumr.4

in

oriier

toperfanr

an

d-to-end

Tlml

Out-of-Seruice Voice andSigdingtest.

Please

read

tk

entimpmcedumBBPI)RBstarting,

.

W~-SetuptbeP~6WO~mnecringtotknetumr.4.

4

conNnuou.dy~'ng

tk

appropriate

sopkey,

p

you2

moll

tbrougb

tk

menu untilp

raacb

yarr

&siradsetting.

A

(up-

hey)

is

used

to

return

to

tkprevious

menu

sektion.

Use

tk

dlBMIsvphey

to

moll

tbmugh theoptions

untilyou

reach

INIF

SETOP

(LED

beside

it

is

illumiMted).

Tben

f&

tbe

stspsbelau:

I

Part

1

-

Interface

Setup

Tlml

corn

FRMlE

CODE

m

MORE

RESULT

LBO

m1

A

ERRINS

A

MODE

MORE

VOICE

SEL<

Access

the Tlm1interface.

w

Access

the

CONFIGURATION

menu.

ScmU through the list

until

you

reach

the appropriate

framingof

your circuit (e.g.,

D4,

ESF,

SLP-96,

or

Om).

Scmllthrough thelist

until

you

reach

the appropriate

dmg

of

your circuit

(e.g.,

BSZS

or

AM).

Scroll through the list

and

set

to

TERM.

See

additional selections.

Scrollthrough the

list

and

set

to

SID.

Scrollthrough the list

and

set

the Line

Build

Out

to

0

dB.

Scroll through the list

and

set

to

m.

Press

the

A

(up-mow

key)

on the

keypad

to

rrturn

to

the

Tlm1

main

m&u.

Set

to

om.

Press

the

A

(up-amnv

key)

on the

keypad

to

rehrrn

to

the

_I3

TlmImain menu.

I

ml

Access

the

MODE

menu.

--I

See

additional

selections.

Places

the

PlREBERD

6000

into

VOICB

mode

Pm

to choose

between

setting

your

IX

channel

or your

RX

w&iJ

channel (toggle

between

RX=<TX-<,

and TX-<RX=<.)

(continued

on

back)

@

1997TelffommuniononsTffhniqua

Corpanfion.

M

rights

reserved

TTC

Technical

Support

1-800-638-2049

FB6000-Tl.FTl.Voice/Cud1.1/3.97

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

w1

of1

I

Part

I

-

Interface Setup

(ant.)

d

m-m

.

.

.-

-

..

r.

4bZ

CHXUP

Selectyour

TX

and

RX

channels.

CHX

DN

4b3

MORE

See

additionalvoice selections.

4c

SIC

Set

to

ON.

(Use

the front panel

keypad

to

set

the

ABCD

signaling

bits forESFframingor

AB

bits for

D4

framing

in

binary format.)

4cl

ENTF.R

Press

to enter the values selected.

5

ENTER

Press

BNlBR

on the

keypad

to

retum

to

the

main

menu.

6

GEN

CLK

Scroll through the

lin

and set to

SYNM

to generaIe internal

timing or

IMF

to recover timing

from

the network

7

ANALYSIS

MODE

Select

CONmWOUS

I

Part

2

-

PerForming the Test

/~the~tintotk~-8~t.iackk

wbkbislocatedon

the

TILT1

I~aceModule

(cloicefrannnLFsiaJqtim

cun

now

k

mjied

on

an individualch@.

1

Press

RESTART

to

dear

alarmsand

begin

the

test.

Verify

that:

A.

FlREBERD

6000's

PATIERN

SYNC

LED

is

illuminated (indicating

a

sgnal

is

present).

B.

HREL3ERD

6000's

PRM

SYNC

LED

is

illuminated

(if

PRM

SYNC

isnot

illuminated,

go back

to

Step

2n

and select

the appropriateframe format).

J

TaMe

1

lists

inrporrantAN4YLFIS

RBSULTS

tbatsbould

be

checked

I

Table

1

-

Analysis Results

T-CARRIBR

RXABCD

Receive

ALW

bits

Table

2

is

a

list

of

IiWEREACB

STATUS

LBDs.

117bm

iUuminated

each

of

tk

status

Dsmntkfollauing:

I

Table

2

-

Interface Status LEDs

CODE

Illuminateswhen

B8ZS

ccding

is

being

received.

ALM

1

Illuminates

when

a

Yellow

Alarm

is

detected

ALM

2

illuminates

when

an

ExcessZeros

Alarm

is

detected

MTR:

Using

tbis

mode,

pw

may

cbeck

tkintegrity

of

tkcircuit

by

insertingandmonitoringmice tm&, andmonita'ngand

tmmittingsignalingbits

on

individudchannelswitbintk

TImTI

bits-. Usingtbis

modegiwa

quickcbeck

oftk

intsgrty

of

tkcircuit

and

mjiespmper

signaling

seguences.

For

example,

you

may

set

tksigndingbitsfor

on-kwh

and

tben

verii

tbat

pmpr

off-book

bitsare being returned

Tebxommoniufions

Tshnlqun

Cnprrulon

"

204W

Obsemtion

Drive,

Gmultom.

Mqluld

20876

Tel.

(800)

638-2049.

(30,) 353-1550

(MD)

PAX.

(301) 353-0234

TTC

Technical

Support

J

*

+-

-

VW

Address:

http://muc.eom

1-800-638-2049

0

1997

Telffommuniarions

Teehniqes

CorponUon.

NI

tighs

reserved.

EB6000-T1.FTl.Voice~Cud1.1/3.97

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

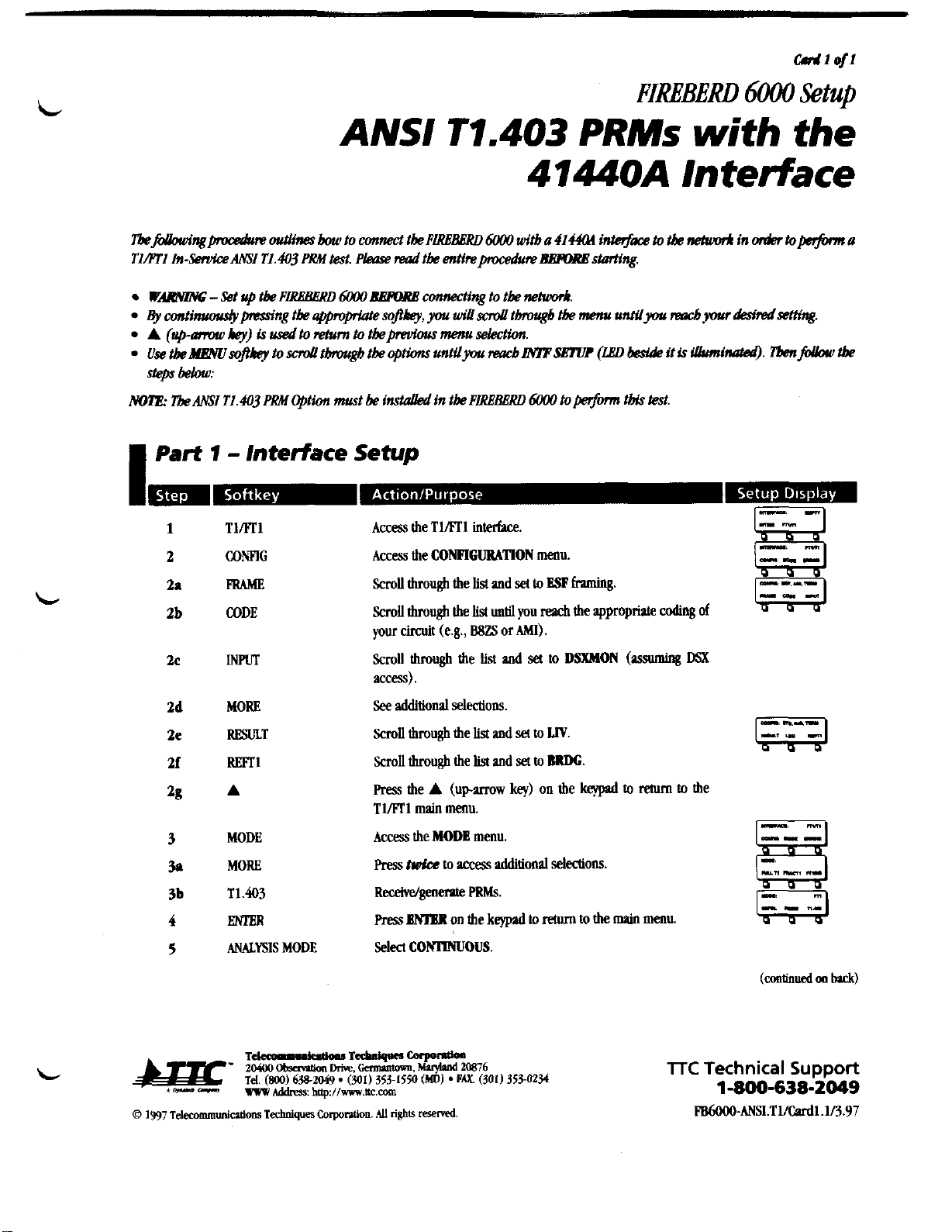

crrJ1

o/l

FIMBERD

6000

Setup

ANSI T7.403

PRMs

with the

4M4OA Interface

Wm

-

Set

up

tbe

F~6000

BERME

connectingto tk

nehmrk.

By

oatinuoudypmnpmnngtbe

applprtate

soPhey,

you willsciwl tbreugb tk

menu

untUpu

dyour

&misetting.

A

(up-

hey)

is

dto

return

to

tkpmdow

menu

selection.

use

tbeblEWsofikey

to

sciwlthgbtk

options

untuyou

reacblMPSE?W

(ZED

!&&

it

is

iUumiMtad).

Tbmjbbw

tbe

steps

below:

MllE:

Tbe

MSI

Tl.43

PRM

Option must be

insrclued

h

tk

PtREBBRD 6000

toperfonntbis&st.

I

Part

1

-

Interface

Setup

Tlrnl

CONFIG

PaAME

CODE

INPUT

MORE

RESULT

m1

A

MODE

MORE

T1.403

rn

ANALYSIS

MODE

Access

the

TIN1

interface.

Access

the

CONFIGURATION

menu.

ScmU through the

list

and

set

to

ESP

framing.

Scrollthrough the

list

until

you

reach

the appropriate

coding

of

your

circuit

(e.g.,

BSZS

or

AMI).

ScmU through the

list

and

set

to

DSXMON

(wuming

DSX

access).

See

additionalselections.

ScmU through the

list

and

set

to

LIV.

Scrollthrough the

list

and

set

to

IMDG.

ResstheA

(uparmwkey)

onthekepiitorehlmtothe

Tlml

main menu.

Access

the

MODE

menu.

Press

mke

to

access

additionalselections.

Receive/genernte

PRMs.

Press~MBllwtbekqlpdtorehlmtothemPinmenu

Select

COmoUs.

(continued

m

luck)

lTC

Technical

Support

1-800-638-2049

w6ooO-ANSI.TllCudl.ll3.97

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

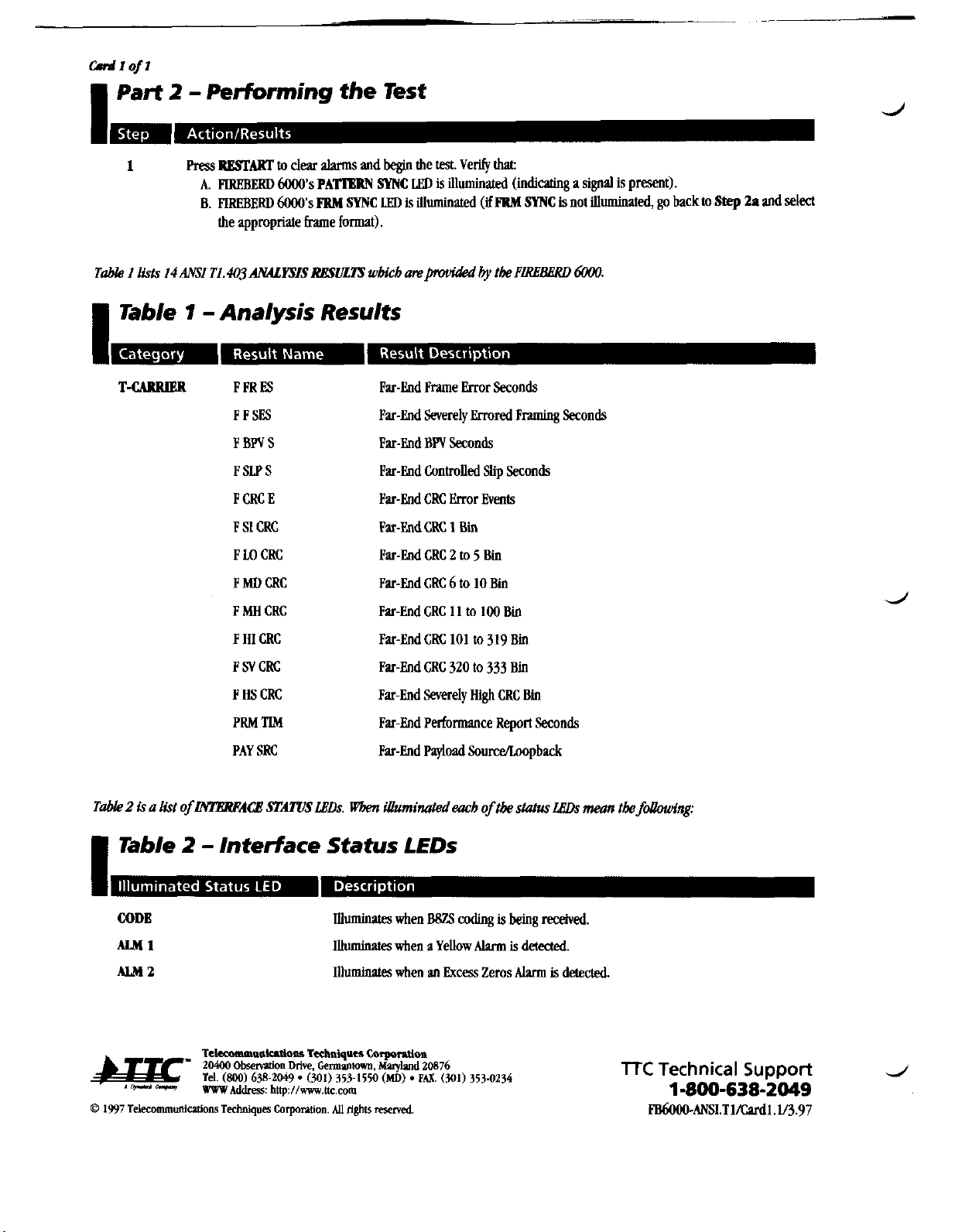

W

Part

2

-

Pehrmingthe Test

1

Press

RBSIAXT

to

dear

alvms

and

begin

the

test.

Verify

that

A.

FlREBERD

6000's

PATlgRN

SYNC

LED

is

illuminated

(indicating

a

signal

is

present).

B.

RREBERD

6000's

FRM

SYNC

LETl

is

illuminaled

(if

PBM

SYNC

is

not

illuminated,

go back

to

Step

Za

and

decl

the

appropriate

frame formal).

I

Table

1

-Analysis Results

T-CARRIER

FPRES

PPSFS

FBPVS

F

SLP

S

P

CRC

E

FSI

GRC

F

U)

CRC

FMDCRC

F

MH

CRC

F

HI

CRC

FSVCRC

FHSCRC

PRM

TIM

PAY

SRC

Par-End

Fme

Error

Seconds

Far-End

Severely

Errored

Framing Seconds

Far-End

BW

Seconds

Par-End

Controlled

Slip

Seconds

Far-End

CRC

Error

Events

Fat-EndCRC

1

Bin

Far-End

CRC

2

to

5

Bin

&-End

CRC

6

to

10Bin

Par-EndCRC

11

to

100Bin

Far-End

CRC

101

to

319

Bii

Far-End

CRC

320

to

333

Bin

Far-End

Severely

High

CRC

Bin

Far-End

Performance

Report

Seconds

Far-End

F'ayioad

Sourcehwpback

Table

2

is

a

list

ofNIBWACB

STAl'USLBDs.

Wkn

Wbenminatedtnch

of

tk

status

LhDs

mean

tk

foUowing:

I

Table

2

-

Interface Status LEDs

Illuminates

when

BBZS

coding

is

being

received.

Illuminates

when

a

Yellow

Alarm

is

detected.

Illuminates

when

an

Excess

Zms

Alvm

is

detected.

TTC

Technical

Support

d

1-800-638-2049

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

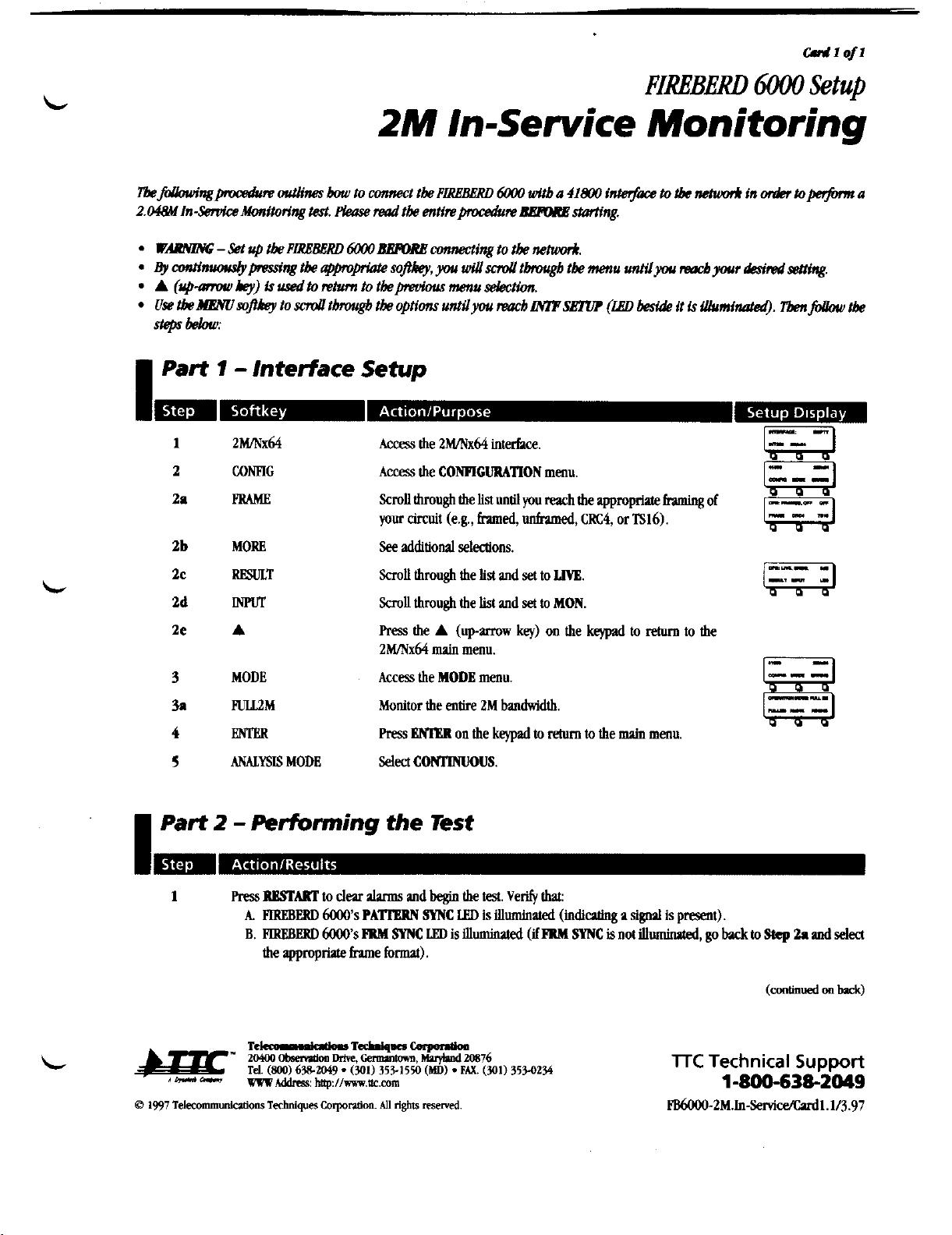

FIREBERD

6000

Setup

2M

In-Service Monitoring

I

Part

1

-

Interface Setup

1

2MINx64

Access

the

2mx64

interhce.

"

P

2

CONHG

Acw

the CONFIGURATIONmenu.

---

2a

PRAME

Scroll

throughthe

list

until

you

reach

the

appropriate

fnming

of

your

circuit

(e.g.,bed,

unframed,

CRC4,

or

TS16).

2b

MORE

2c

RmULT

2d

INFWr

2e

A

3

MODE

3a

lmL2M

4

m

5

ANALYSIS

MODE

See

additiond selections.

ScmU

throughthe

list

and

set

to

LIVE.

Scroll

throughthe

list

and

set

to

MON.

Press

the

A

(upurow

key)

on

the

keypad

to

return

to

the

2MINx64

main

menu.

Access

the MODE menu.

Monitor

the entire

ZM

bandwidth.

Press

BNIHll

on

the

keypad

to

return

to

the

main

menu.

Select

COmOUS.

I

Part

2

-

PerFonning the Test

1

Press

BESWRT

to

deu

alvms

and

b&

the

test.

Verify

that:

A.

PIREBERD

6000's

PATlBRN

~Yhk

LED

is

illuminated

(indicating

a

@

is

p-1).

B.

PIREBERI)

6000's

INRI SYNC

LED

is

illmimed

(ifINRI

SYNC

is

not

illuminated,

go

back

to

Step

2.

and

select

the

appropriate

he

format).

TTC

Technical

Support

180063&2049

m-2M.In-Senice/Cudl.1/3.97

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

I

Table

1

-

Analysis Results

d

TGARlllBR

PAS

ERR

MFASERR

REBE

ERR

BIT

SUP

CODE

ERR

+LvI

dB

-LvI

dB

Rcv

FREQ

SIGNAL

PAS

Errors

WAS

Errors

(if

~~16

is

me)

REBE

Errors

Bit

Slips

(used

with

RRTl)

Code

Errors

(per

EllT

0.161)

Positive

Receive

Si

level

Negative Receive Signal level

Receive

Frequency

lTC

Technical

Support

d

1-800-638-2049

PB6000-2M.h-S&ce/Cardl.1/3.97

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

crrJ1afz

FIMBERD

6000

Setup

2MINx64

Out-of-Service

BERT

I

Part

1

-

Interface

Setup

2mK64

CONFIG

PRMiE

MORE

RESULT

rn

I50

A

MODE

mM

A

ERRINS

A

MORE

mrr

TSXW

TSX

DN

Access the

2MINx64

interface.

Access the

CONFIGURATION

menu.

ScmU

through the

listuntll

you

reach

the appropriatefnming

of

your circuit (e.g.,

framed,

unframed,

CRC4,

or

lS16).

See

additionalselections.

Scroll

throughthe list

and

set

to

SlD.

ScmU

through the

list

and

set

to

IlWA.

ScmU

through the

list

and

set

theLine

Build

Out

to

0

dB.

Press

the

A

(uparrow

key)

on

the

keypad

to

return

to

the

2MINx64

main

menu.

Access the

MODE

menu.

Test

the entire

2M

bandwidth.

Press

the

A

(up-mw

key)

on the

kqlnd

to

retum

to the

2MNx64

main

menu.

Access the

BRROR

MSBRllON

menu.

Press

MB

md

hm

each

error

type

OW.

Press

the

A

(up-mw

key)

on the

keypad

to

return

to the

2Wx64

main

menu.

See

additionalselections.

Select

the timedot

0-31

to

be

displayed

in

the

RX

BlTE

resuh

(allows you

to

see

the

bytes

on

a

specifictimeslot).

Select the timeslot you

wish

to

monitor.

(continued

on

back)

TTC

Technical

Support

1-800-638-2049

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Wlof2

I

Part

7

-

Interface Setup

(cont.)

a

m-m

..

I.

-

-

.B

0.

A

AL4RMS

MORE

A

MORE

FRWORD

WAS

A

WAS

ENTER

DATA

GEN

CLK

ANALYSIS

MODE

Press the

A

(up-mow key) on the keypad

to

return to the

2M/Nx64

main menu.

Access the

ALARMS

menu.

Turn

each

type

of em

OFF.

See

additionalselections.

Press the

A

(up-mow key) on the keypad

to

return

to

the

2Wx64

main menu.

See additionalselections.

Access the

FRAMING

BIT

menu.

Edit

the binary digitsusing the keypad.

Press

ENTER

to

set

the

digits (seethe note below).

Press

the

A

(up-mow key) on the keypad

to

return

to

the

Frame Word menu.

Edit the binary digits using the keypad. Press

BNlgR

to set the

digits

(see

the note below).

Press

ENlUt

on the keypad to return to the main menu.

ScroU through the

list

and select a

data

panem.

2"-1

is

the

recommended

data

pattern. Additional

stress

patterns are lo-

catedon the frontpanel or in

AUX

41.

(Press

the

MOM

key

as

uecessaty

in

AUX

41

to

see

the additionalpatterns.)

ScmU through the list and set to

SWlX

to generate

internal

timing or

IWF

to

recovertiming fromthe network

Select

CONTINUOUS.

NO~:Mult~

alignment

si&aUow

meiw'ngequipmentto

a&

the

appmpriateABCD

signaling

bits

witb

tbeir

mspond-

ing voice

channels.

Setting the

NPAS

andMFAS

bit

will

enabk

you

to

determine whetberthe mtsignaling

bits

are

being sent

tbrougbout the netwk.

I

Part

2

-

Performing the Test

1

Press

ReSFART

to

clear

alarms

and

begin

the test. Verifythat:

A.

HREBERD

6000's

PATl%RN

SYNC

LED

is illuminated (indicatinga signal is present).

B.

FlREBERD

6000's

PRM

SYNC

Ln,

isilluminated

(if

FRM

SYNC

isnot illuminated,go back to

Step

2a

and select

the appropriateframeformat).

(continued on

Cud

2)

lTC

Technical

Support

J

1-800-638-2049

FB6000-2M.Out-S&cdCard1.2/3.97

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

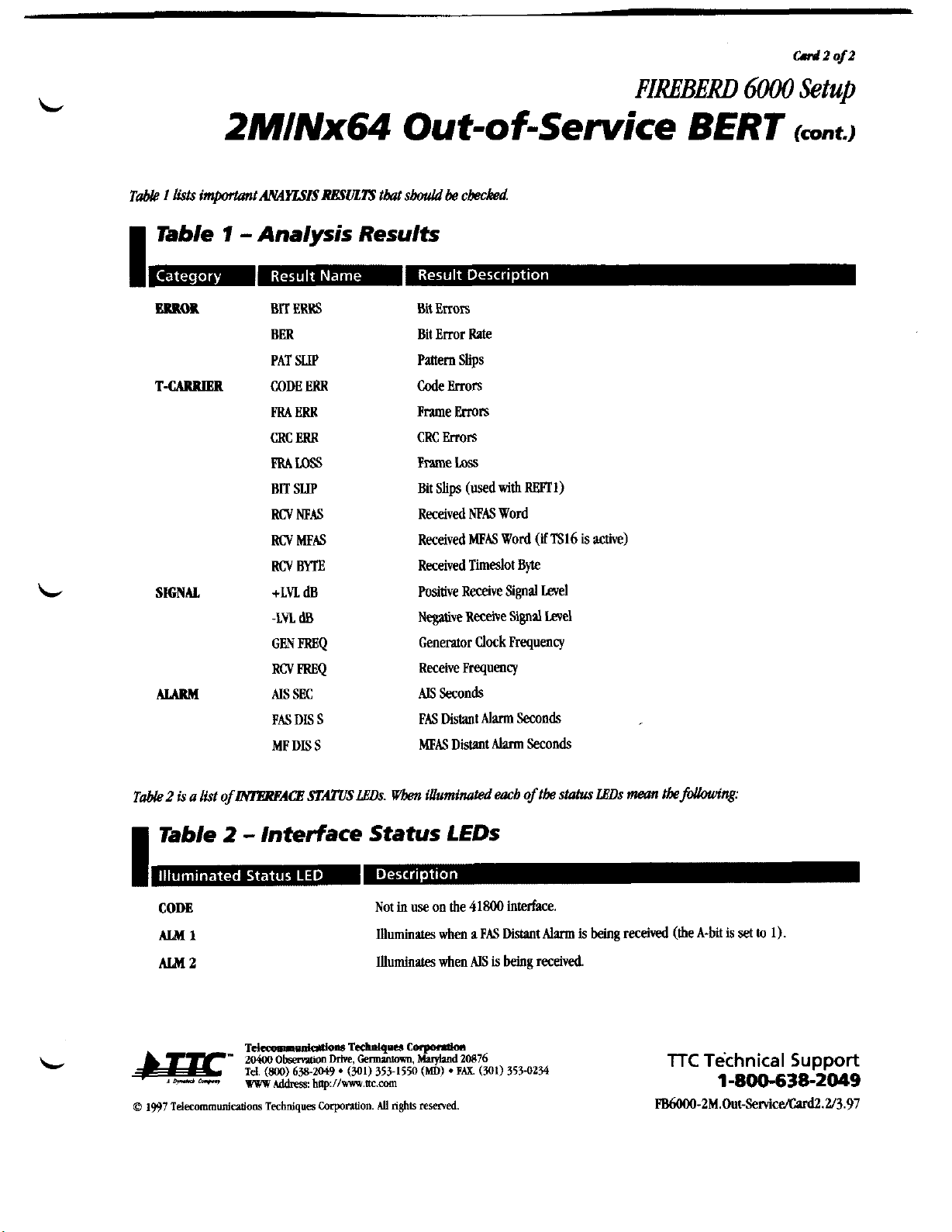

-

2MINx64

Out-of-Sewice

BERT

Tab&

I

lists

intportmrtMYLFISRESULTS

tkt

sbouki

&

cbecM

I

Table

7

-Analysis Results

BUM

BIT ERRS

BER

PAT

SLIP

T-CARRIER

CODE

ERR

PRA

ERR

CRC

ERR

PRAUlSS

BIT

SUP

RCVNEAS

RCV

MEAS

RCVm

L

SIGNAL

+LVL

dB

-LvL

dB

GFN

ERGQ

Rcv

mEQ

ALARM

.US

SEC

FAS

DIS

S

MF

DIS

S

Bit Errors

Bit Emr

Me

Panern

Slips

Code

Errors

Frame

Errors

CRC

mrs

Frame

Loss

Bit

Slips

(used

with

RE3Tl)

Received

MAS Word

Received

MFAS

Word

(ifTS16

is

active)

Received

TimeslotByte

Positive Receive

Signal

Level

Negative

Receive

Signd

level

Generator

Clock

Frequency

ReceiveFrequency

AIS

Seconds

FAS

Distant

Alm

Seconds

MEAS

Distant

Alarm

Seconds

T&

2

is

a

list

of

IMgRPAQI

STATIiS

LEDs.

Wben

illuminated

each

of

tbe

stahrs

LhDs

rnan

tbefhhdng:

I

Table

2

-

Interface Status LEDs

CODE

ALM1

ALM2

Not in use on

the 41800

interface.

Illuminates

when

a

PAS

Distant

Alarm

is

being

received

(the

A-bit

is

set

to

11,

Illuminates

when

AIS

is

being

received.

TTC

Technical

Support

1-800-638-2049

PB6000-2M.Out-SetVic~.2/3.97

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

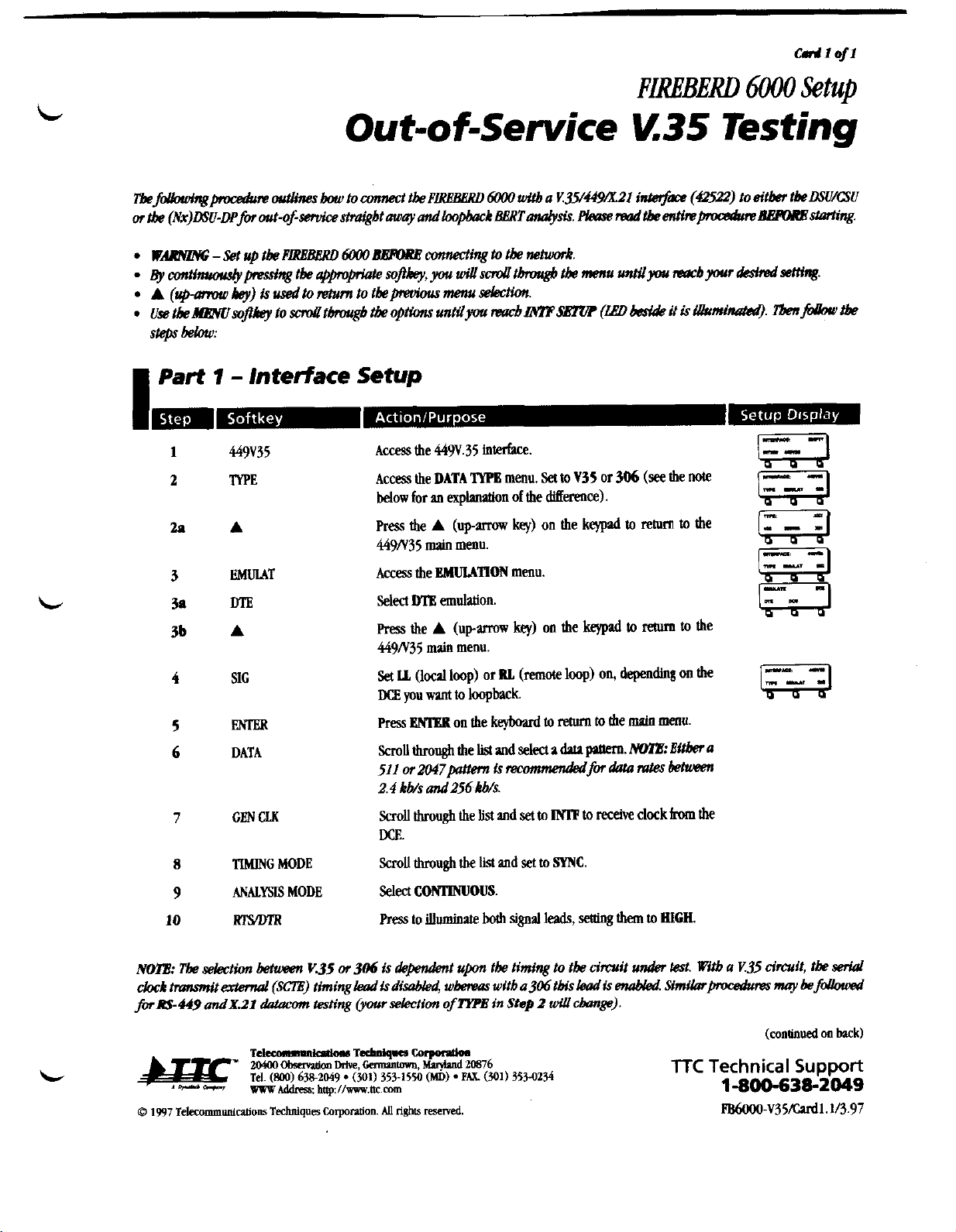

FIREBE..

6000

Setup

Out-of-Service

Y.35

Testing

I

Part

1

-

Interface

Setup

1

449V35

Access

the

449V.35

interhce.

2

TYPE Access

the

DATA

TYPB

menu.

Set

to

V35

or

306

((see

the

note

below

for

an

explvwion

of

the

ditIerence).

2P

A

Press

the

A

(upmw

key)

on

the

keypad

to

return

to

the

449N35

main

menu.

3

EMULAT

Access

the

EMULATION

menu.

3a

DTE

Selea

MB

emuhtion.

3b

A

m

the

A

(upanow

key)

on

the

kqpd

to

return

to

the

449N35

main

menu.

Set

Ih

(local

loop)

or

RL

(remote

loop)

on,

depeoding

on

the

DCE

you

wvlt

to

loopback

5

MTER

Press

ENlER

on

the

keybud

to

return

to

the

maio

menu,

6

DATA

Scroll

through

the

list

and

seled

a

data

patlera.

htHB:

Bitber

a

511

or

2047pattem

is

tmmnrendadfor

data

mtes

khueen

2.4kWs and256kWs.

7

GEN

CU(

~voUthroughthelistands~to~toree~clwkhthe

m.

8

TIMING

MODE

ScmU

through

the

list

and

set

to

SYNC.

9

ANALYSIS

MODE

Select

CONIWUOUS.

10

lrlMn'R

press

to

illuminate

both

signal

leads,

seaing

them

to

HIGH

NOTE:

Tk

&tion

betmtw

V.35

or

306

is

dejbdmt

upon

tk

timing

to

tbe circuit

under

W.

Witb

a

Y.35

circuit,

tk

serid

chk

tmmit

ertsntd

(SCE)

timing

leadis

diulMsd,

wh

wltb

a306

tbh

lead

is

enabled

Simibrpocsdures

may

kfouougd

fOIRS449andX.21

dntacan

&sting

(your&tion

ofTtPE

in

Step

2

ruillc&nge).

TTC

Technical

Support

l-8OO-638-2O49

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Cad1

of1

I

Part

2

-

Performing the Test

mm

J

1

Press

RIWART

to

dear

alarms and

begin

the

test.

Verify

that:

A. FIREBERD

6000's

PATI'ERN

SYNC

LED

is

illuminated

(indicating

a

signalis

present).

I

Table

1

-

Analysis Results

ERROR

BIT

ERRS

Change

in

Logical Value of

Bit

BER

Ratio

of Number of Errored

Bits

to

Receive

Bits

PAT

SLIP

An

Addition or Deletion

of

Bits

PBRPOEMANCE

GERR-SEC Emred

Seconds

TlME

EA

SEC Emred

Analysis

Seconds

SIGNAL

Rev

PREQ

Receive Frequencj

GEN

FREQ

Generate Frequency

ALARM

PAT

UlSS

Count

of

Pattern

Losses

C-D

CH.4

Cloc!dDafa

Phase

Changes

DAT LOSS Count of

Data

losses

CLK

UlSS

Count

of

Clock

losses

NOTE:

Ifyou

me

receivinga

hrge

numberofenors,your received clock

may

be

fe.

Ifthereceived clock ismissing

w

unusable

(a

hrge

numberof

C-D

ChX

cbrmges is

&

an

indication),the

FIRBLEW

6W

RdClock option (option

6W4)

enuhks

tbe

Dmto extracta clock

from

the

receiueddata.

Tbiswillenuhkyou to

determine

whether tbetransmisfionline

w

theclock is

tbe source of

errors.

See

thesetup belorujbr

using

theRdClockOption:

I.

Set

~~G

MODE

to

RBCOVD

(tbis

enables

tbe

PIREBERD

bWO

to

wcom

timingfmm transitionsintheincoming

data).

2.

Rw

tbeMENUso~?kqandsdthgbthelistandset to

SYMlWFRh'Q.

NOTE:

TheRenwered Clock

Option

only operates

up

to

rates of520kbh.

lTC

Technical

Support

d

1-800-638-2049

FB6000-V35/Cud1,1/3.97

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

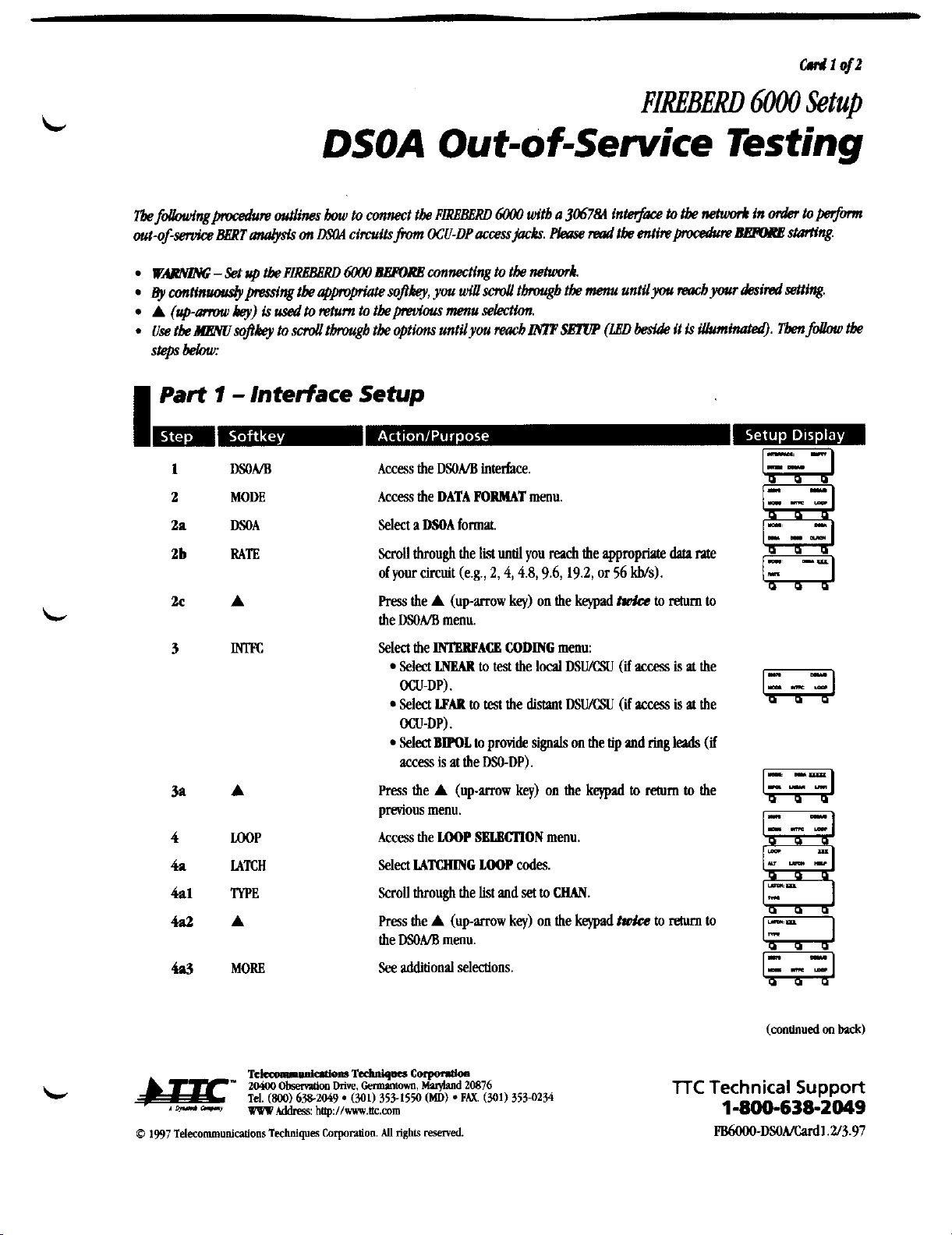

c#r

1

ojz

FIREBERD

6000

Setup

DSOA

Out-o f-sewice

Testing

Tbe

fdbwingpocedun

outlines

tmu

to connect tk

PLRBBGRD

6WO

witb

a

306784

intet$ace

to

tbe

whmr.4

in

&

toperfonn

out-ofservice

aBRT

aaEysis

on

aFOA

circuits

from

OCU-DP

accessjacks.

Fkw

Plaaw

tbe

entinpocedum

BEFME

stariing.

WARNZIW;

-

Set

up

tbe

PLRBBBRD

6W0

dlBPORB

connectingtotknehuwk.

~y

mtinuoudypmdng

tk

ajpvpriate

sopkey,you

dsd

thgb

tk

menu untilyou

reacb

your

&mi

Wing.

A

(up-amnu

key)

is

usedto

nhun

to tbepmfous menu

selecNa.

.

Use

tk

HEWsopkeyto

sd

tbrargb

tk

optionsuntilyou

raacb

LWP

SETUP

(LBD

beside

it

is

iUuminatm9.

Tbenfollow

tbe

steps

bebw:

I

Part

1

-

Interface

Setup

DSONB

MODE

DSOA

RATE

A

m

A

rnP

LATCH

lYPE

A

MORE

Access

the

DSOA/B

interface.

Access

the

DATA

POIMAT

menu.

Select

a

DSOA

format

Scrollthrough the

list

until

you

reach

the appropriale

data

me

of your circuit (e.g.,

2,4,4.8,9.6,19.2,

or

56

Ws).

Press

the

A

(up-arrow

key)

on the

keypad

twh

to

rehm

to

the

DSONB

menu.

Selectthe

lMgllPACB

CODING

menu:

Select

LNEAR

to

test

the

local

DSU/CSU

(if

acm

is

at

the

OCU-DP).

Select

LPAR

!a

test

the

distaot

DSU/CSU

(if

access

is

at

the

OCU-DP).

Select

BWOL

to

provide

signals

on the tip

and

ring

leads

(if

access

is

at the

DSO-DP).

Press

the

A

(up-mw

key)

on the

kqpad

to

return

to

the

previous menu.

Access

the

LOOP

SBLBCTlON

menu.

Select

MTCHING

LOOP

codes

ScroU through the

list

and

set

to

WAN.

Press

the

A

(up-arrow

key)

on the

keypad

twh

to

return

to

the

DSOA/B

menu.

See

additionalselections.

TTC

Technical

Suppoa

1-800-638-2049

FB6OOO-DSOA/Cud1.2~3.97

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

This manual suits for next models

1

Table of contents