the very reason you need to safety test

every chassis that leaves your shop. It

only takes one leaky chassis to put you

out of commission so you are unable to

work. It only takes one to damage your

expensive test instruments and put them

out of service for a week or longer. Or, it

only takes one zapped customer to bring

a lawsuit against you and your shop. It

only takes one before you realize that it

costs you more not to make the leakage

test on every chassis that goes out the

door.

Most technicians add on an extra charge

to the customer’s bill for performing the

leakage test. They find that most

customers don’t mind paying an extra five

dollars if it means safety for themselves

and their family.

What Causes Leakage?

Basically, any path that will place the

customer into either diret or indirect

contact with the AC line is dangerous.

There are many different ways in which

this can happen. The following is a list of

some of the most common causes of

leakage:

Shorted Antenna Bypass Capacitors:

You may see a lot of shorted antenna

bypass capacitors after a thunderstorm.

The capacitors are in series between the

antenna terminals and the chassis to

isolate the hot chassis from the antenna.

When one of these capacitors is shorted,

the customer notices no difference in the

operation of their receiver because the

RF signal passes through the shorted

capacitor just as well as through the good

capacitor. The problem, however, is the

antenna terminals have raw AC on them.

Improperly Installed Tuner:

Occasionally, replacement tuners are

installed improperly or with the wrong

kind. Isolation capacitors must be

installed properly to avoid the AC line

being tied to exposed metal parts. Also,

insulated shafts on tuners should be

replaced with a similar kind to avoid a

shock hazard on the tuning knob.

Conductive Knobs: If the TV being

serviced has control shafts that are

connected directly to a hot chassis, the

knobs on these shafts must be insulating-

type knobs. Many times, however, knobs

that have been replaced are metal or

chrome plated which may conduct current

resulting in a shock hazard.

Defective Isolation Transformers:

Older TV receivers often have guilt-in

isolation transformers that are supposed

to isolate the metal chassis from the AC

line. But, these older transformers

occasionally develop leakage between

the primary and secondary windings,

causing a hot chassis. This is especially

dangerous on the older sets with metal

cases or with metal pans covering the

bottom of the chassis. All of the exposed

metal becomes a shock hazard.

AC Bypass Capacitors: These

capacitors connect between the AC line

and the chassis in most electronic

devices that use isolation transformers.

The capacitors bypass RF interference,

picked up by the metal chassis, to the AC

line for shielding purposes. Older

capacitors were often the wax-coated

paper type which often develop leakage

as the paper dieletric absorbs moisture.

In some cases, a capacitor shorts

completely, causing a direct connection

between the AC line and the chassis.

These capacitors, like antenna bypass

capacitors, are commonly damaged

during thunderstorms.

Bent Rabbit Ears: Many receivers have

rabbit-ear antennas designed to slide

down inside the back of the case.

Generally, there is a plastic tube inside

the case to isolate the metal antenna

rods from the chassis. But the rods often

get bent. When the bent rods are pushed

down to the “nested” position, they touch

the hot chassis. Not only is the exposed

end hot, the wire coming out the back of

the chassis to connect to the antenna

terminals also carries the full AC line

voltage.

Improper Installlation of Parts:

Forgetting to replace an insulating piece

of “fish paper” under a component.

Foreign Objects Touching the AC Line:

Allowing a piece of wire or solder to fall

between one side of the AC line and the

chassis.

A Broken Safety Ground: The broken

gound may allow a shaft or control to

“float”.

Using Long Metal Screws: Screws that

are too long and go all the way through

the plastic mounting tabs and touch the

metal chassis.

Adding An Earphone: Accessory jacks

on an set that does not have an isolation

transformer – imagine the shock hazard

when connectd directly to the listener’s

head!

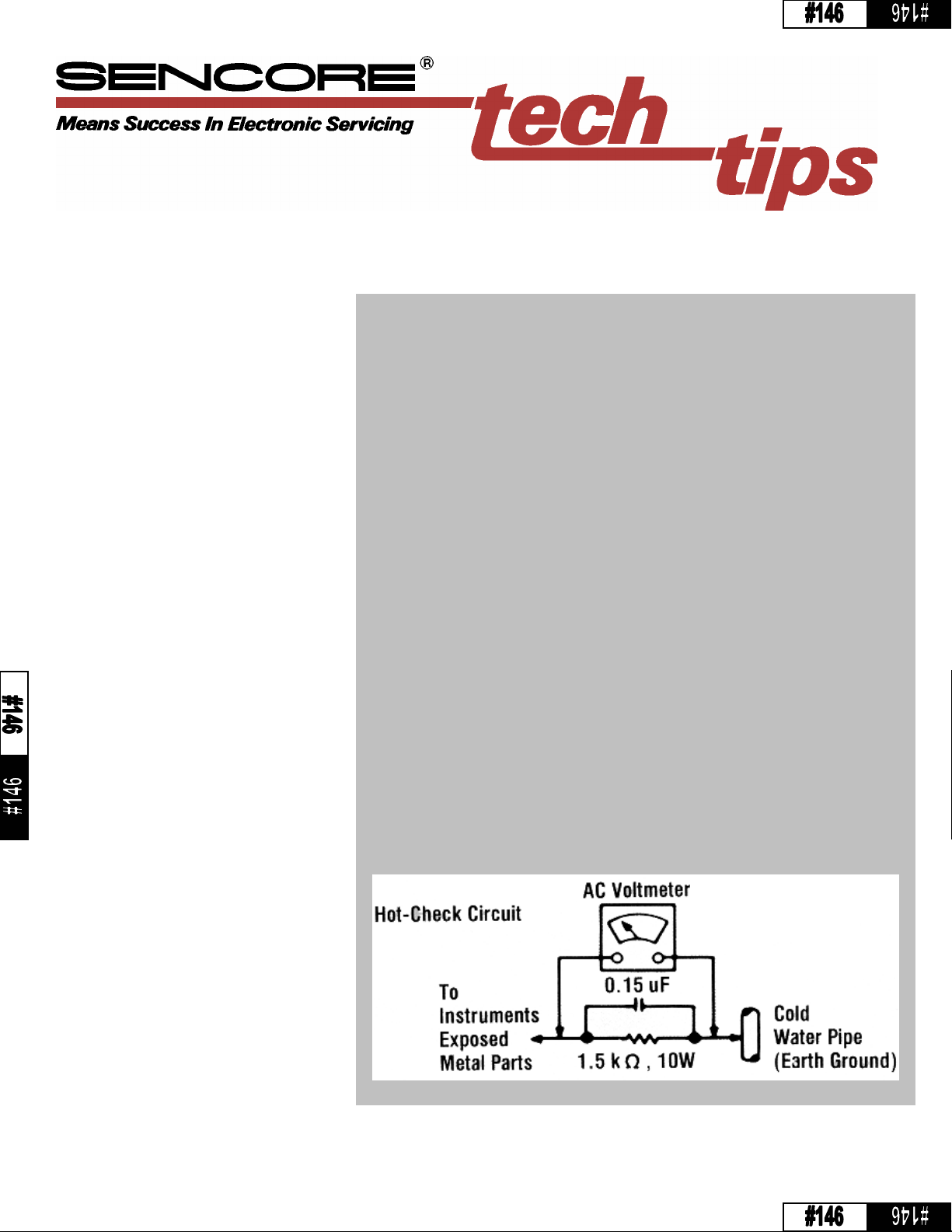

Fig. 2: To make a safety leakage test with your PR57, simply plug the

chassis into the POWERITE and touch the probe to all exposed metal

surfaces.