It is important to review all the parts that came with your kit. The list below is what you

should have received to complete your kit. If you find anything missing, contact us:

Qty Description

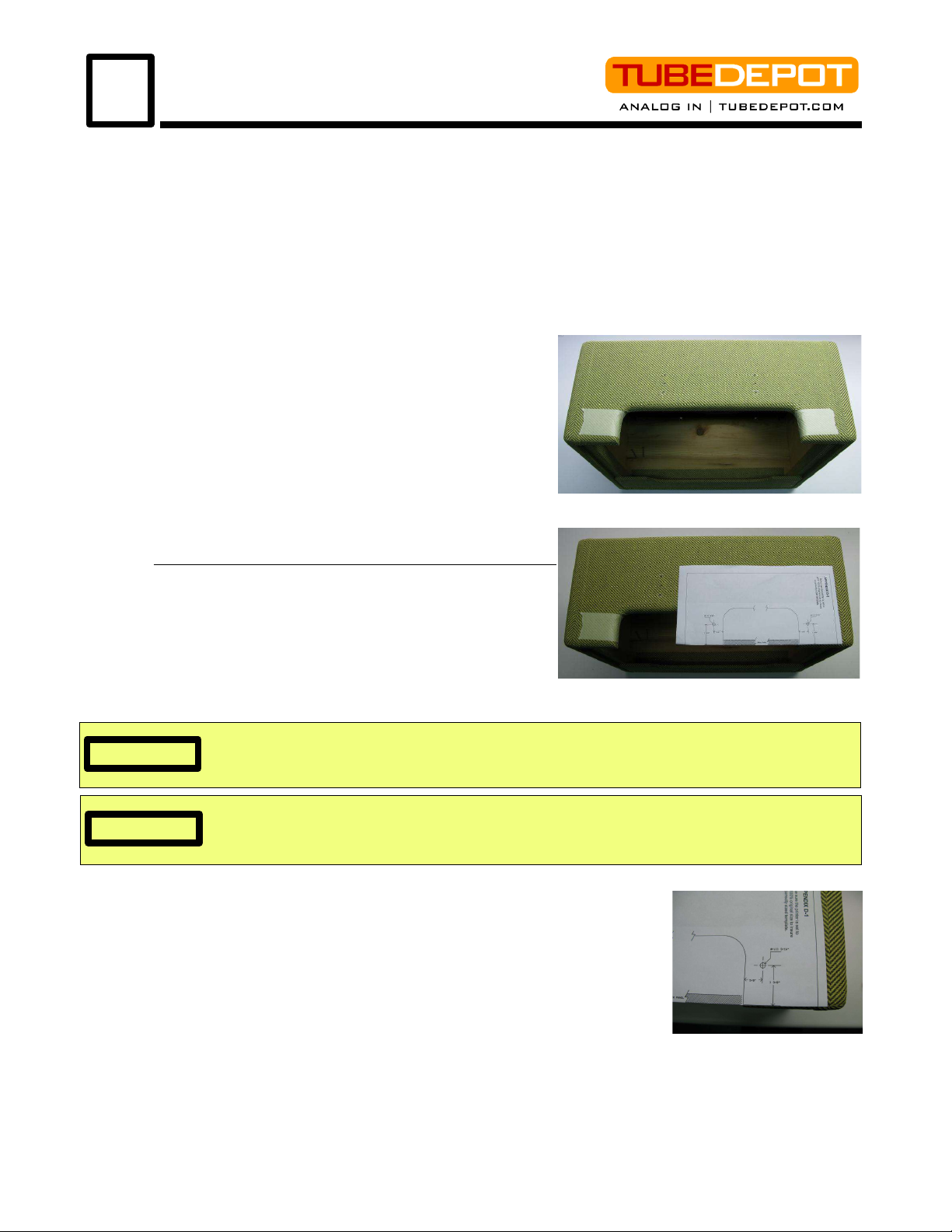

Speaker, Chassis, Cabinet, PC Board

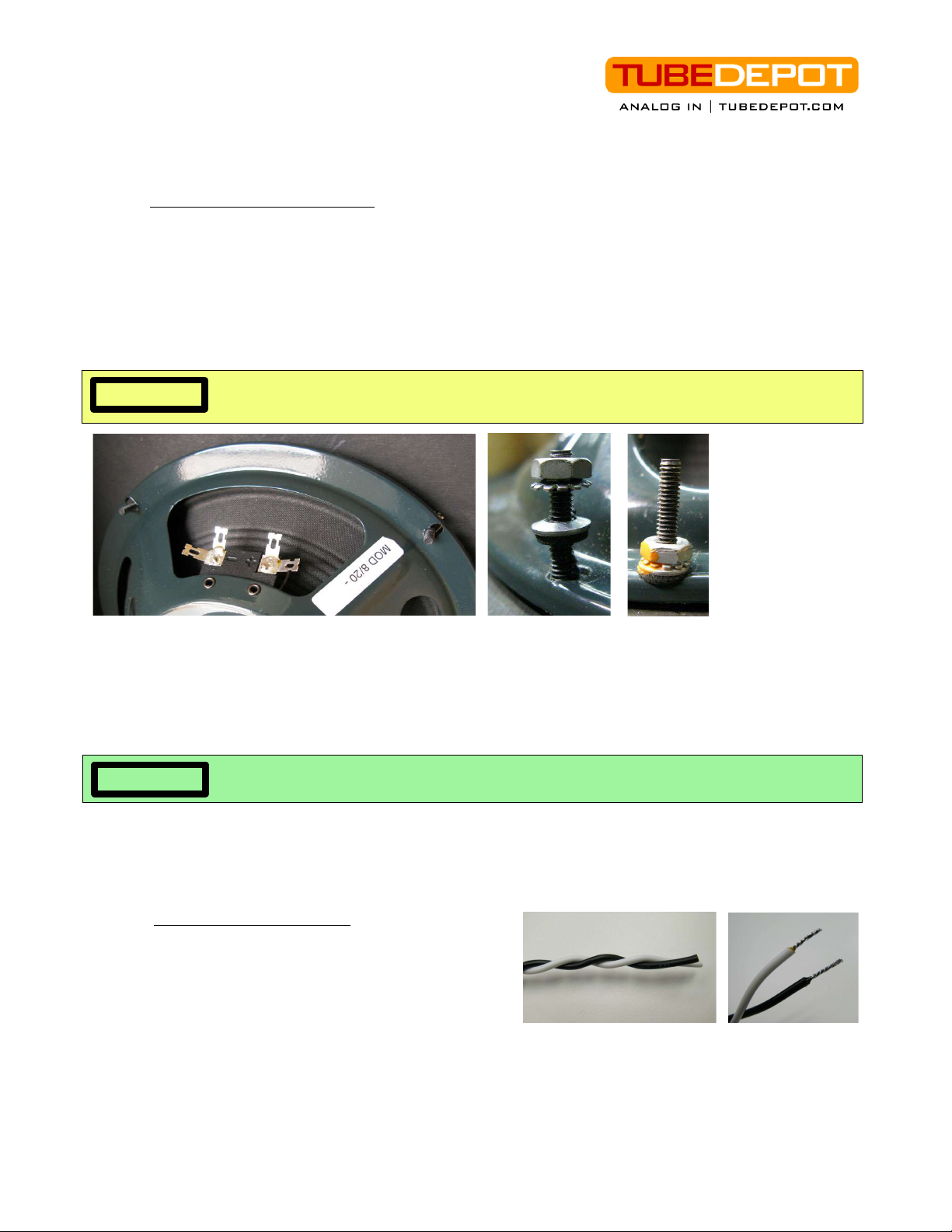

1speaker, 12" Jensen MOD, 8ohms

1chassis, steel chrome plated 5E3

1cabinet, tweed 5E3

1PCB board, 5E3

Transformers

1 tPower transformer, ClassicTone 18017

1 Output transformer, Classictone 18002

Tubes

15AR4 / GZ34 rectifier tube various brands

26V6GT beam power tetrode various brands

212AX7 / ECC83 dual triode various brands

Hardware, Cabinet (provided with cabinet)

4 bolt 1 1/2” 6x32 copper plated truss screw baffle mounting bolts

4 bolt 1 1/2” 8x32 flat head, black oxide coated speaker mounting bolts

4nuts, KEPS 6x32 baffle mounting nuts

4nuts, KEPS 8x32 speaker mounting nuts

1 handle, brown flat leather w/ mounts and screws handle assembly

4 feet, metal glide w/ screw glide feet

8 screw, #6 oval head phillips, 1 1/4” stainless steel back panel screws

Hardware, General

3knob, vintage pointer volume and tone knob

1fuse holder, conical cap, vintage style fuse holder

2fuse, 3AG 2A slow-blow fuse (one extra fuse)

1lamp holder indicator lamp holder

1jewel, red red jewel

1lamp, #47, 6.3 V lamp

4jack, 12A, shorting, Switchcraft ¼" input jacks

2jack, 11A, open, Switchcraft ¼" speaker output jacks

9washer, lock; 3/8" lock washer for jacks and potentiometers

1plug, Switchcraft ¼" speaker phone plug

2switch, toggle SPST; Carling power and standby switches

2washer, lock 1/2” lock washer for switches

1power cord, grounded three prong, 12' power cord

1strain relief, Heyco strain relief

1nylon cable clamp cable clamp

1screw, zinc plated #8 x 5/8", phillips flat head cable clamp screw

2screw, zinc plated 6-32 x 3/8", phillips pan head V1 tube socket shock mounting

2washer, flat zinc plated, #6 screw V1 tube socket shock mounting

2grommet, rubber 1/4" chassis hole / #6 screw V1 tube socket shock mounting

2grommets, rubber 3/8" hole rubber chassis grommets

4washer, neoprene bonded speaker mounting

2bolt, 1 1/2" 1 x32 truss screw chassis mounting

2nuts, KEPS 1 x32 chassis mounting

1 screw, zinc plated 6-32 x 1/4", phillips pan head tube socket mounting

13 nuts, KEPS 6x32 tube socket / PC board mounting

2nuts, 6x32 preamp tube socket mounting

4screw, zinc plated 6-32 x 1/2" phillips pan head PC board mounting

4standoff, nylon; L = .25"; id = .14 "; od = .25 " PC board mounting

4nuts, KEPS 8x32 power / output xfmr mounting

2nuts, 8x32 power xfmr mounting

TubeDepot.com 3

Parts Inventory

3

TubeDepot.com

1958 Vanderhorn Dr.

Memphis, TN 38134

(877) 289-7994