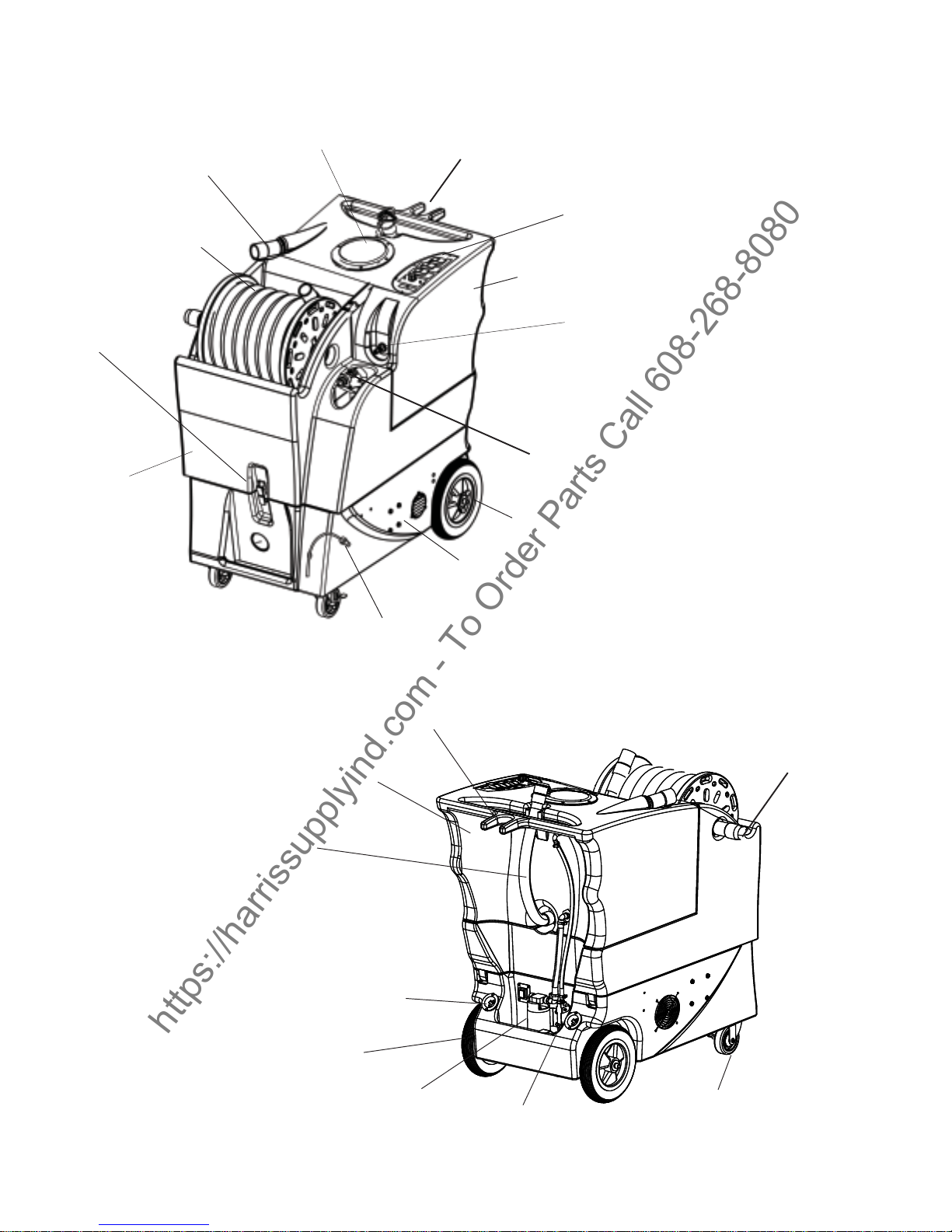

TERMINATOR

PART LIST 120V

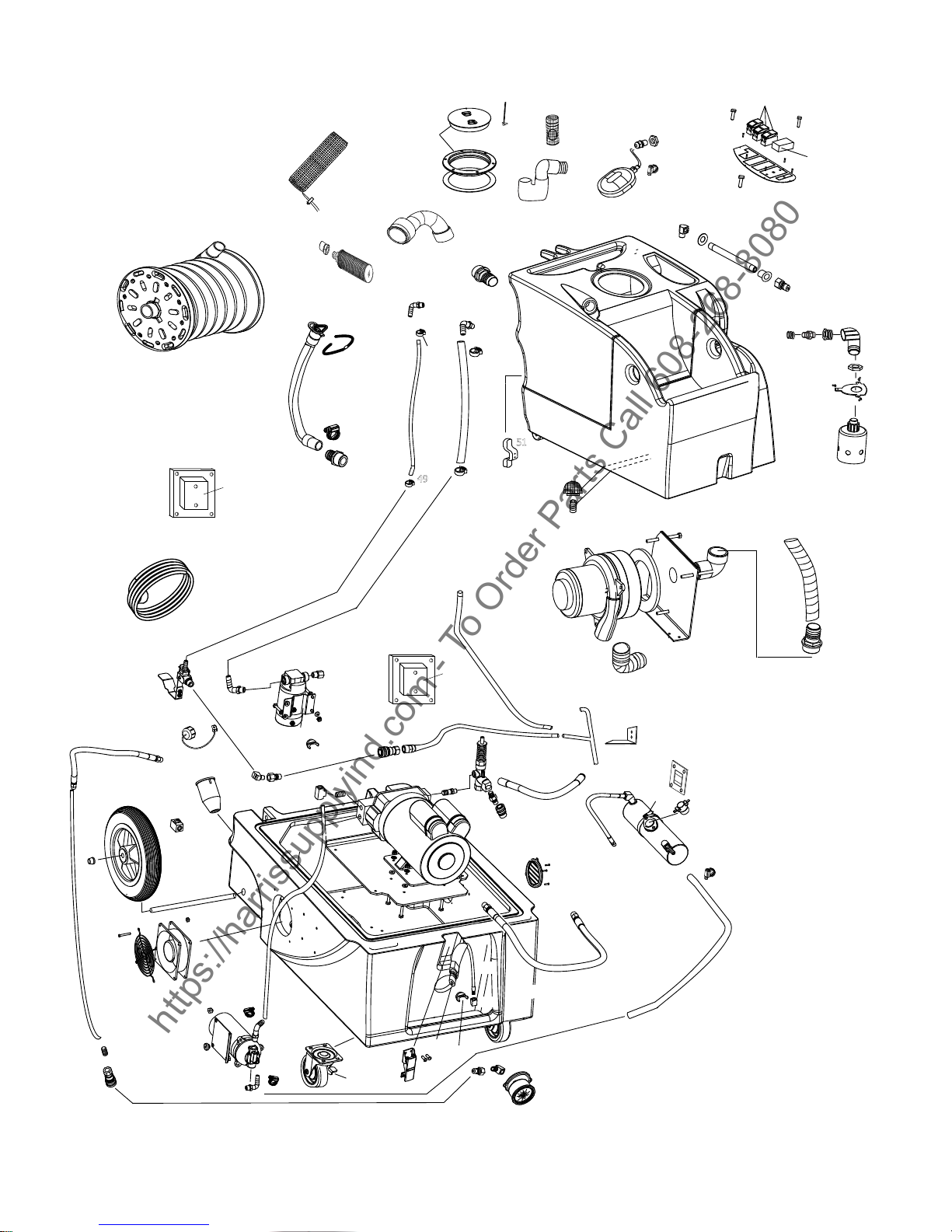

67 1310A Float,Auto-fill,hightemp.

69 1530 “T” hose assembly, complete

75 220 Quick disconnect, female

78 219 Quick Disconnect, male, open

79 220 Quick Disconnet, female, open

80 1530 Hose, power prime inlet, 30”

82 1163 Valve,pressureregulator

83 92A Nipple, S/S, 1/4 mpt

89 455 Bracket,heatermount

90 FP256 Heatrepairkit

91 76A Hose Clamp, 2-3/4”

92 FP420 Hose,PumptoGauge,complete

93 FP371 HeatExchanger,complete

95 928 Louver,3”,includesscrews

98 1530A Hose,fromunloader,33”

99 1162 HoseAssembly,32”,bypass

100 925 Hose,3/8”X45”pumptoheater

102 152 “T”,brass/1/4npt

104 FP373 Pump & motor, complete

105 1062 Recepticle, power cord

106 957 Pump,auto-dump

106A 1324 HoseConnector,kdumppumpout

107 237 Cap,withchain

108 1325 Elbow,auto-dump

109 1057B PowerCord,25ft,yellow

110 4405A Relay,20Amp

110A 2025 Heat sink plate

111 1164 Valve,powerprime

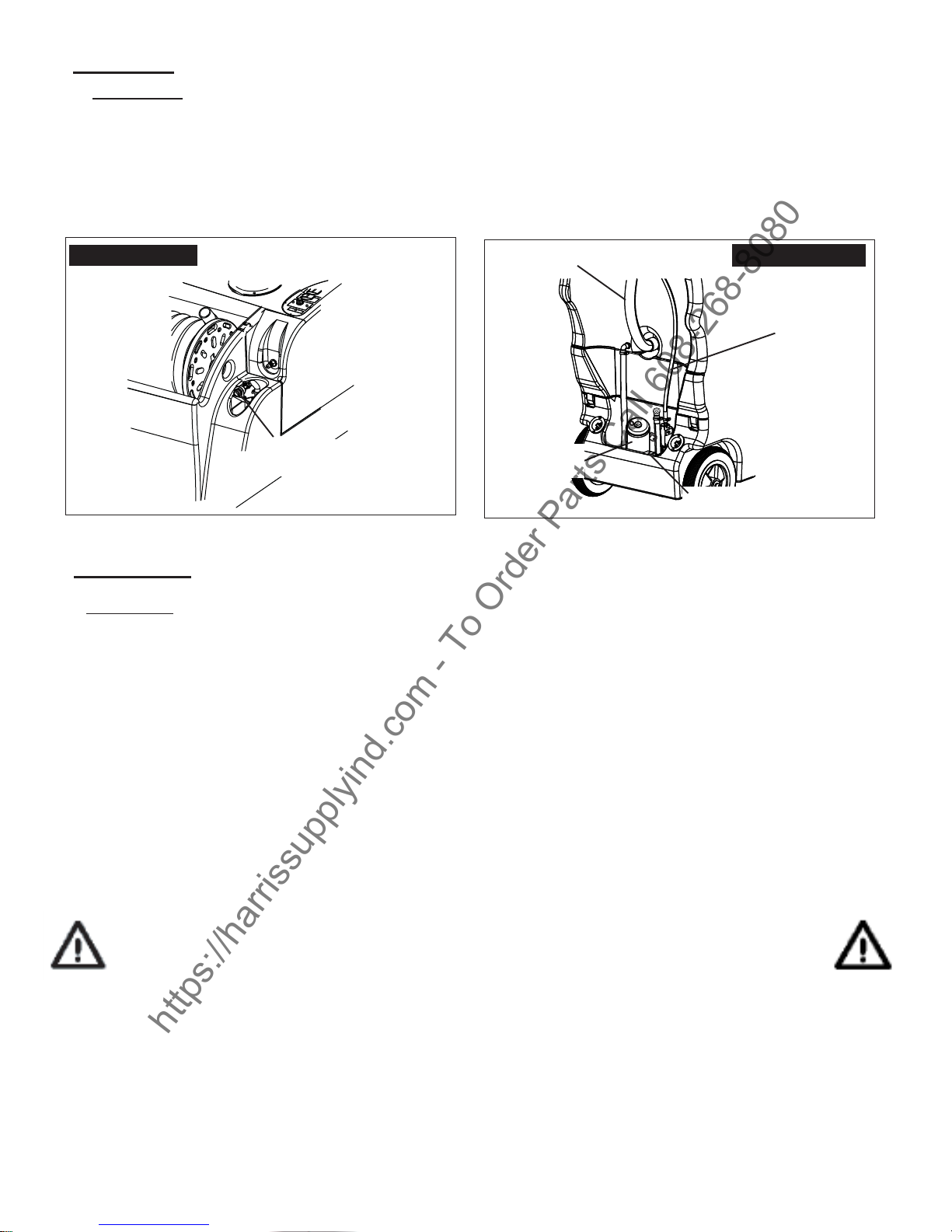

111A 1299 Pedal, power prime

112 1530C Hose, to highpress.outlet,30”

117 1280 Elbow, 90 degree, brass

121 2084A Wheel, 10”

122 27A Axle cap

123 910-20.75 Axle,1/2”X 21-3/4”

124 1158 Plate, pump mounting

125 16 Locknut, 6-32

126 2B1 Screw,6-32X 2”

127 2015 Guard, fan

128 2014 Fan, cooling, 100CFM

130BKCR BLK Base compartment, black

131 108A Elbow, 90 degree, pump outlet

132 2066 Pump, 150 psi

133 1081 Elbow, 90 degree, pump inlet

135 905 Castor,4”

135A 905A Brake,forcastor

136 1413 Clip Holder, for hose

137 FP416 Hoseassy,lowpress.outltet

138 1043A Gasket

139 219 Quick disconnect, male

140 91 Elbow, 90 degree

142 2166 Gauge,1200psipressure

143 908A Latch

144 21C Screw, 8-32X 5/8”

145 946A Hose, 1/2” 500 PSI, 6-3/4”

1 1303 Switch Plate

2 78 Light,green,120V

3 78B Light,red,120V

3A 227 Light,green,230V

4 56220001 Switch, selector, ON/OFF/ON

5 FP345 Switch, ON/OFF,with actuator

6 FP364 Ballfloat&manifoldassembly

7 929B Ballfloat

8 2068 Float,Auto-Dump

8A 1518 Hoseclamp

9 230 Cordretainer,watertight

10 805 Chain,lidretaining

11 1074 Gasket,recoverylid

12 2086A Lid,andring,6”

14 937 Bushing,PCV

15 2069B Filter,Auto-dump

16 1060C Cap, drain hose

17 1130 Strap,velcro

18 1060B Hose, drain

20 91 Elbow,90degree,brass,1/4mpt

21 1141 Washer,S/S

22 1146 Pipe,S/S,1/4mptbothends

23 1143 Spacer

24 45 Quick Disconnect male, 1/4 pt

25 1184 Hose connector

26 1533 Connector,malegardenhose

27 1571 Bushing, 1” x 1/2”

28 1534 Elbow, 1” 90º

29 2170 Locknut,1”

30 1320A Bracket,Auto-fillvalvemounting

31 1518 Hose Clamp

32 907 Hose Barb,1-1/2” hose

33 1137 Adaptor,ABS,1-1/2”

33A 1140 Elbow, 90º, ABS

33B 1494 Bushing,ABS

33C 1428 Strainerbag

33D 1465A Cordlock

34 HKCR-1 HoldingTank,white

35 VKCR-1 Recovery Tank, white

36 FP414 Reel,withhoses,complete

37 1309 Hose, power prime, 3/8” X 21.25”

38 166 Hoseclamp

39 946A Hose, 1/2” 500 PSI, 17”

41 1115 Elbow,90deg,3/8”hoseX1/4mpt

46 1113 Hose Barb, elbow

47 92B Nipple,PVC,1/2npt

48 207A Filter,Pumpinlet

49 1401 Clamp,quickdisconnect,small

51 CWKC-BLK CordWrap,black

61 1131 Elbow,PVC

64 926 Manifold, vacuum

65 FP323 Vacuum motor, w/gasket, complete

66 430 Vacuumhose, 1-1/2”X 7.75”

66A 1136 Vacuum hose, 1-1/2” X 25 , clear

ITEM PART No. DESCRIPTION ITEM PART No. DESCRIPTION

https://harrissupplyind.com-ToOrderPartsCall608-268-8080