Contents

Introduction...........................................................3

Safety.....................................................................5

SafetyAlertSymbol.........................................5

GeneralSafety.................................................5

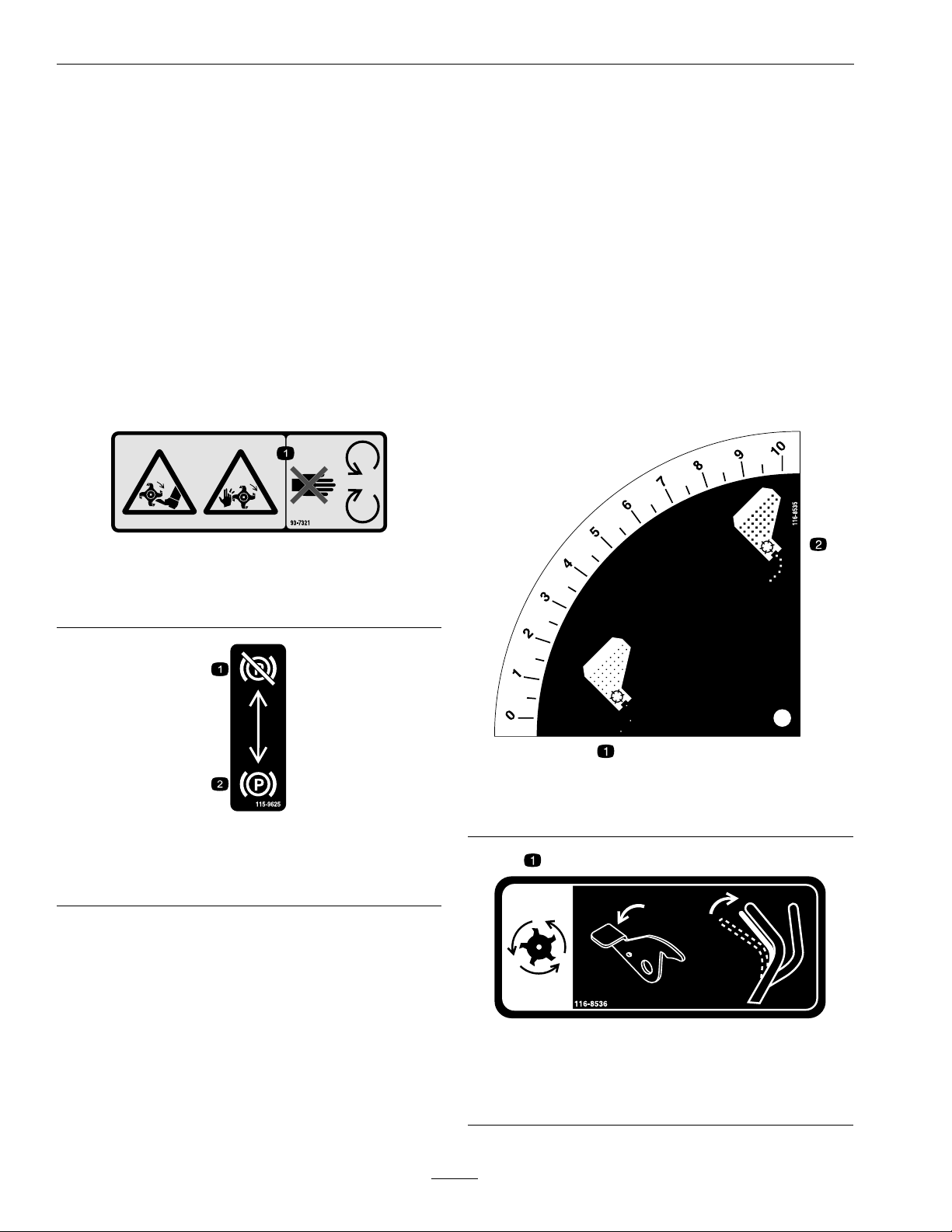

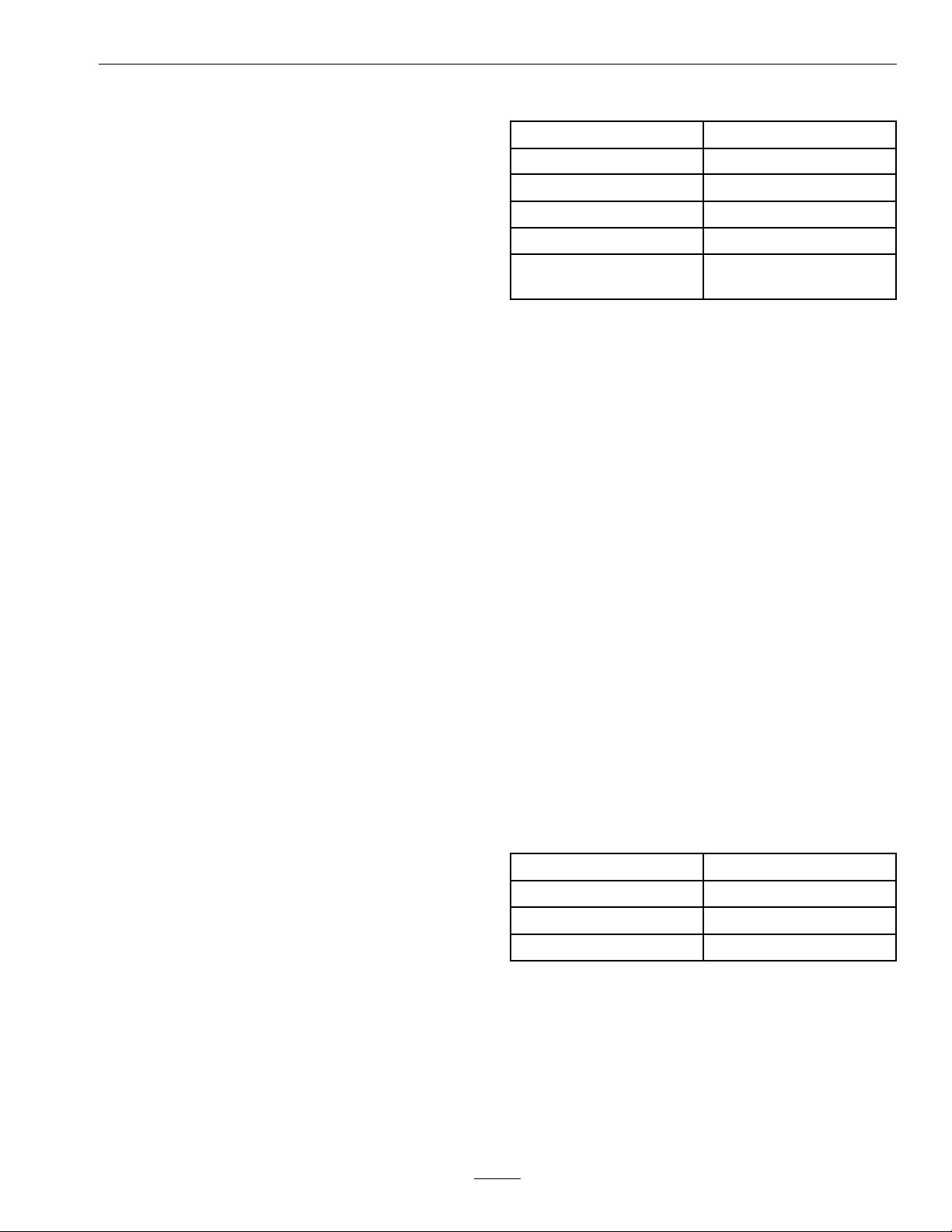

SafetyandInstructionalDecals.......................6

Specications.........................................................9

Systems...........................................................9

Dimensions.....................................................9

TorqueRequirements......................................9

Setup.....................................................................10

SetuptheHandle............................................10

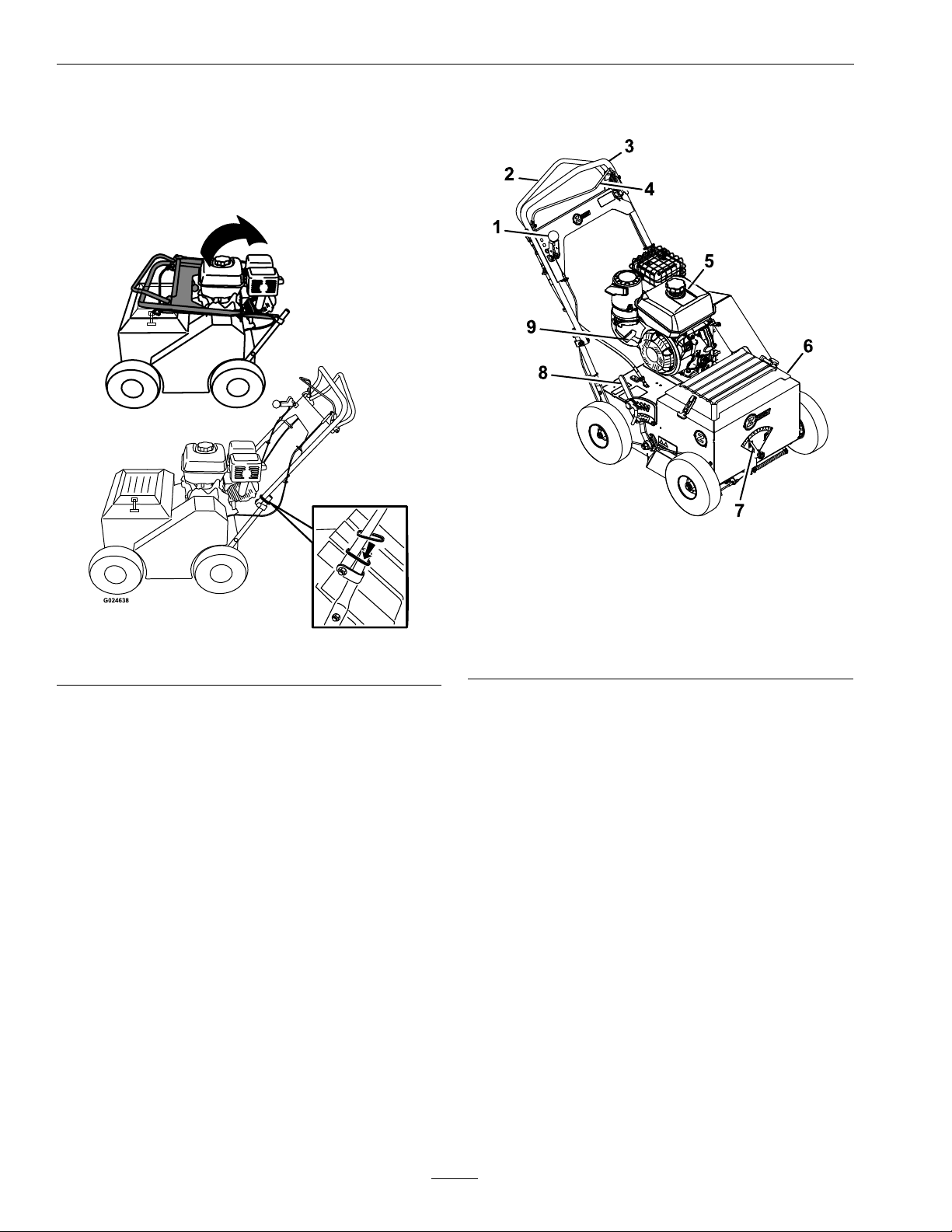

ProductOverview.................................................10

Operation..............................................................11

Controls.........................................................11

BeforeOperation...........................................12

OperatingInstructions...................................14

DuringOperationSafety.................................14

OperatingTips...............................................18

AfterOperation..............................................19

Transporting..................................................19

Maintenance..........................................................20

MaintenanceSafety.............................................20

RecommendedMaintenanceSchedule(s)............20

PeriodicMaintenance........................................21

EngineMaintenance.......................................21

EngineSafety.................................................21

CheckEngineOilLevel..................................21

ChecktheBlades............................................21

CheckforLooseHardware.............................22

ServiceAirCleaner.........................................22

ChangeEngineOil.........................................23

CheckConditionOfBelts...............................23

LubricateGreaseFittings................................23

CheckSparkPlugs..........................................23

CheckSparkArrester(ifequipped)..................24

ChecktheSeedGate.......................................24

ThreadLockingAdhesives..............................24

Adjustments......................................................25

AdjustingtheSelf-PropelDrive......................25

AdjustingtheSelf-PropelDriveBelt

Tension......................................................25

AdjustingtheSeedGateClosed

Position......................................................26

Cleaning............................................................26

CleaningandStoringSafety.............................26

CleanEngineandExhaustSystem

Area...........................................................26

CleanDebrisFromMachine...........................27

CleanDebrisBuild-UpUnder

Machine.....................................................27

CleaningUndertheBeltCover.......................27

CleaningtheSeedGate...................................27

WasteDisposal...............................................27

Troubleshooting....................................................28

Schematics............................................................29

CaliforniaProposition65Warning

Information...............................................30

4