5

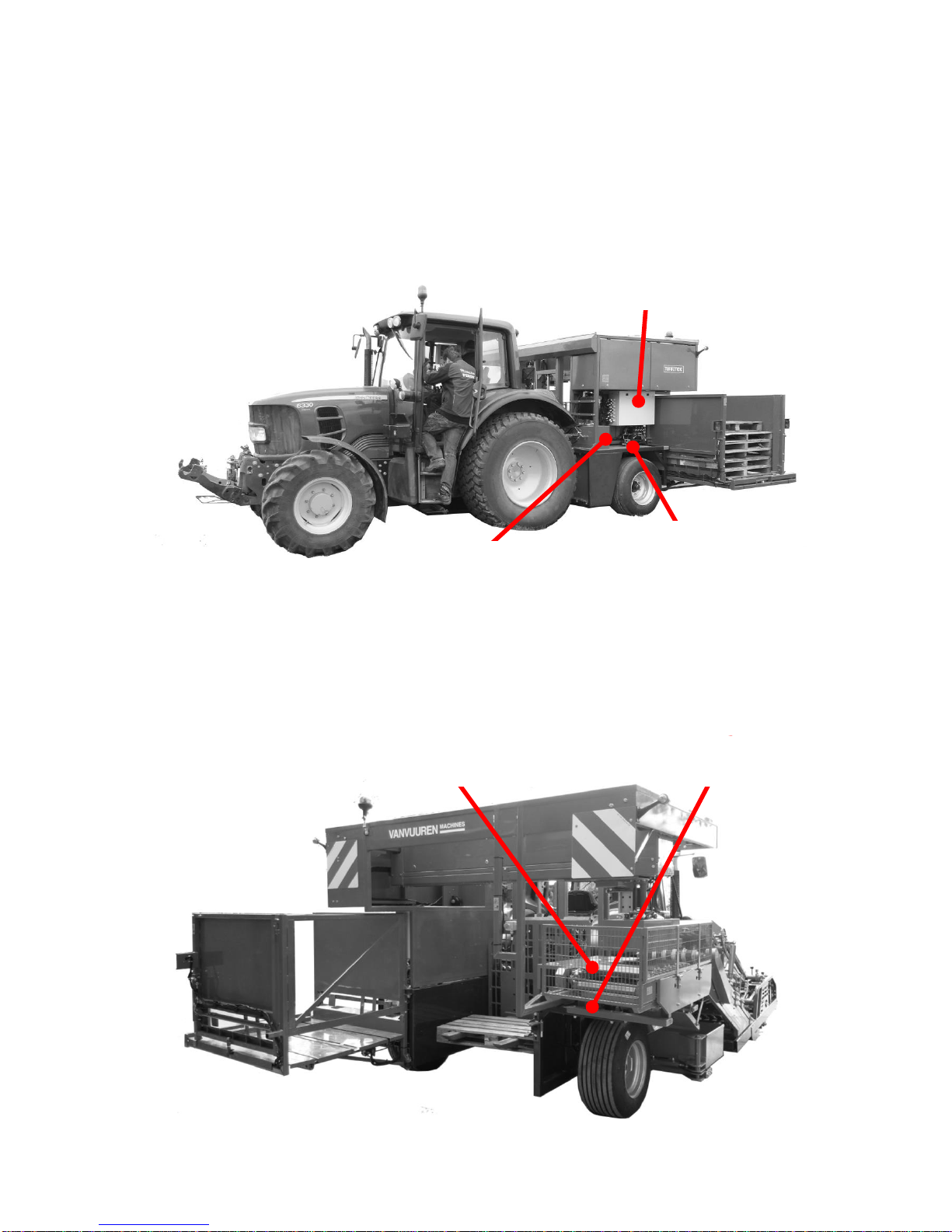

3. Basic operation of system:

A shoe is mounted on front of the Turftick sod harvester which can move freely in all

directions. A spring pulls the shoe against the sod edge. The shoe will follow the sod edge.

If the tractor steers too much to the left, the spring will pull the shoe to the right side until it

follows the sod edge again. The movement which the shoe makes, is being read by the shoe

sensor. The control unit sends the necessary output to the steering cylinder of the front wheels

of the tractor. The (right) tractor wheel sensor is monitoring the amount of steering and will

stop the wheels from steering when it has reached its targeted angle. At the same time the rear

wheels are steering (at all times). Each trailer wheel has its own sensor and steering and

proportional valves.

WARNING

Always switch on PTO while driving. Without a running PTO the trailer wheels will

never steer!! Prevent hazardous situations which if not avoided could result in serious

injury or death.

The system usually needs to be set up only once. The procedures consist of:

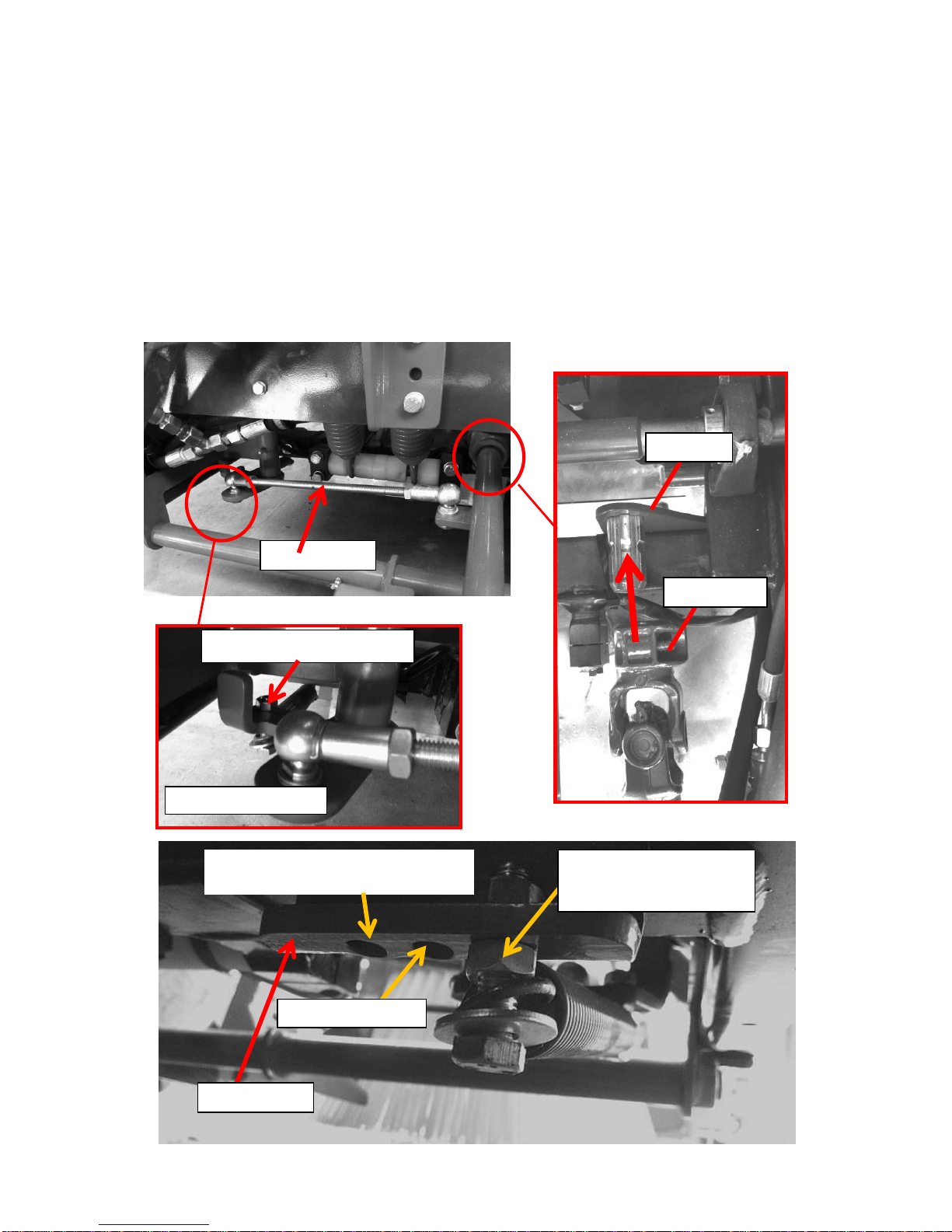

*calibrating tractor wheel sensor: while tractor wheel is steering straight, adjust sensor

position until its status LED becomes blue.

*calibrating trailer wheels: adjust trailer wheel sensors until trailer wheels are steering straight

while tractor wheels are steering straight.

*calibrating shoe sensor: adjust shoe sensor position until sod strip (left behind on field) is +/-

1 cm while ‘Offset’ button is set on 5/6. Readjust if ‘Offset’ button has too little range.

*Adjust oil pressure for Autosteer valves steering tractor front wheels.

All sensors are set up once and never needs re-adjustments, unless it is being replaced with a

new sensor. If you replace a sensor, then it needs to be calibrated again (explained further in

this manual).

The control box has an ON/ OFF switch and an offset knob. This offset knob will regulate the

width of the sod edge which the sod harvester will leave behind while harvesting. If the range

of the offset is not properly set, adjustment of the shoe sensor can change the offset range.