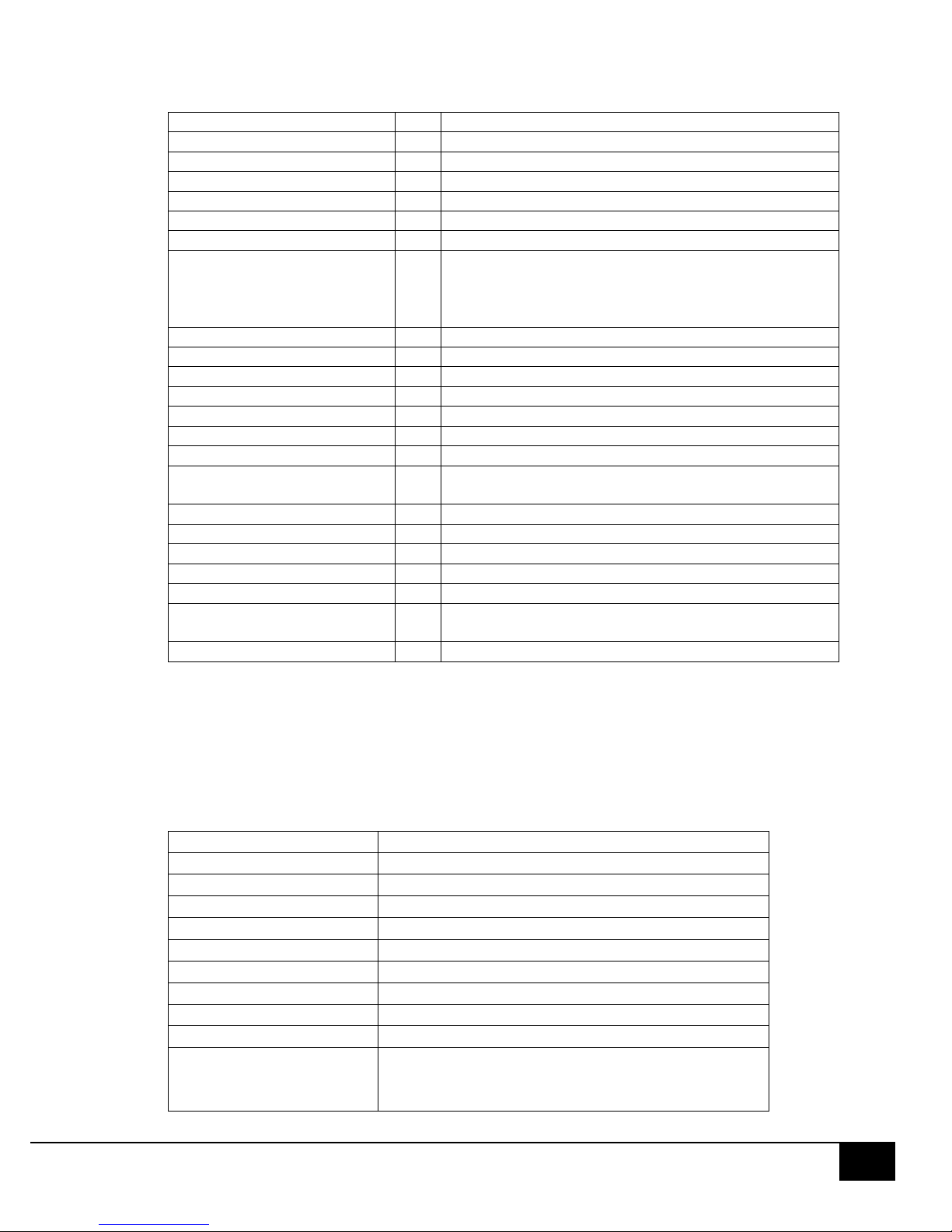

SAMPLING

Sampling is the process by which the instrument measures and stores readings from its gas

specific sensors. Each sample consists of a series reports measured over successive time

intervals, this is the Reporting Interval. The series of reports which make up the sample is

known as the time series. The reported readings will be the average (or sometimes the peak)

value over the reporting interval. Average (or peak) readings are also recorded over the

duration of the sample.

Sampling may be started and stopped automatically as defined by the Feature Flags. Automatic

samples are generally aligned with 1 minute boundaries.

The shortest reporting interval is one second, the longest 50 minutes. The recommended

reporting intervals are between 1 minute and 15 minutes, these give the best compromise

between memory use and time resolution. The shortest sampling period is one report interval,

the maximum many days.

For those instruments with a display output, analogue output or micro-website, the Viewing

Interval specifies how often the output is updated. The output is the average (or peak) over the

specified viewing interval. The viewing interval can be in the range 1 second to 30 minutes and

is independent of the reporting interval.

The instrument’s memory can hold up to 100 samples each consisting of many reports. A

sample is identified by its Sample Number. When the memory is cleared the sample number is

reset. The total number of samples measured by the instrument over its life is the Sample

Total.

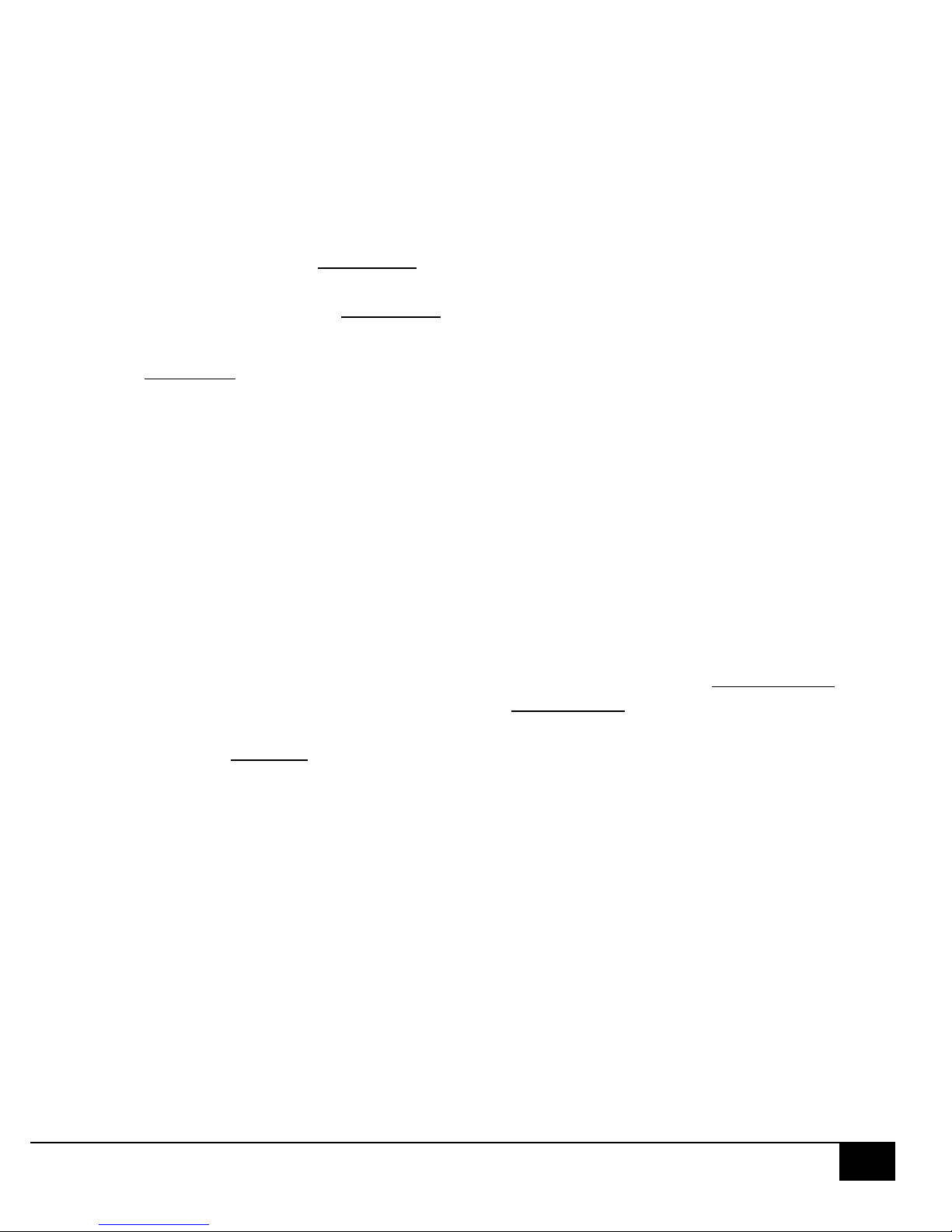

SAMPLE CONTROL FEATURE FLAGS

If Automatic Start is set, sampling will automatically start on the next 1 minute boundary after

the instrument is switched on. If Timed Sample is set the sample will last for the Duration

number of reports (specified in the Instrument Settings) and, if Automatic Start is set too,

another sample of the same duration will start immediately. This process will carry on till the

memory fills when a Memory Full Fault Flag will end the current sample and prevent another

restarting.

If Circular Buffer is set, the last sample (i.e. the one just finished) will be overwritten if the

Instrument Settings Sample Stack value equals 0, if it equals 1 the last but 1 will be overwritten

and so on. Hence it is possible to create a stack of N samples that will overwrite forever.

If New Sample Daily is set a new sample will start at precisely midnight but only if Automatic

Start is set. This can be combined with the Circular Buffer flag and the value of the Sample

Stack to create a rotating, N-day, sample block.