Manual 2003 Rev D p/n 2003 1

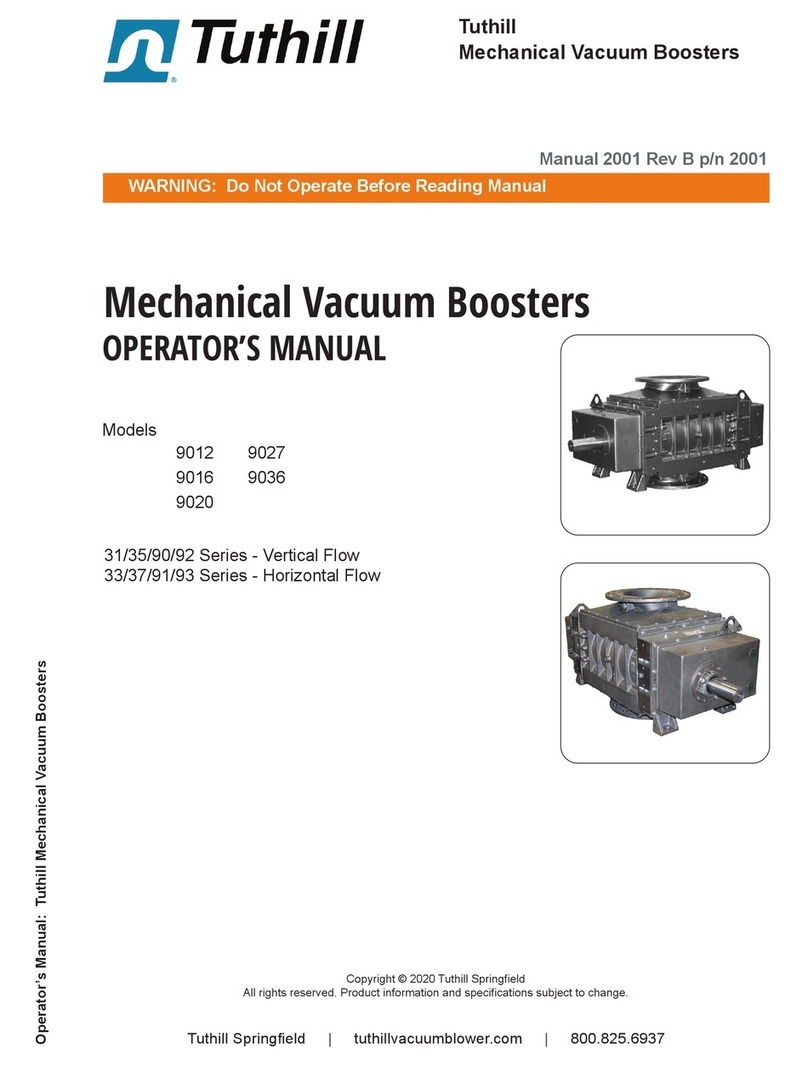

CONGRATULATIONS on the purchase of a new

Mechanical Vacuum Booster from Tuthill Vacuum

& Blower Systems. Please examine the booster

for shipping damage, and if any damage is found,

report it immediately to the carrier. If the booster is

to be installed at a later date, make sure it is stored

in a clean, dry location and rotated regularly. Make

sure covers are kept on all openings. If the booster

is stored outdoors, be sure to protect it from

weather and corrosion.

Mechanical Vacuum Boosters are built to

exacting standards and, if properly installed and

maintained, will provide many years of reliable

service. Tuthill urges you to take time to read

and follow every step of these instructions when

installing and maintaining your booster. Tuthill has

tried to make these instructions as straightforward

as possible. Tuthill realizes getting any new piece

of equipment up and running in as little time as

possible is imperative to production.

OTE:NRecord the booster model and serial

numbers of the machine in the

OPERATING DATA form on the inside

back cover of this manual. Use this

identication on any replacement part

orders, or if service or application

assistance is required.

This manual covers the installation, operation,

and maintenance of the Tuthill Vacuum & Blower

Systems Mechanical Vacuum Boosters.

APPLICABLE DOCUMENTATION

The applicable documents associated with this

manual are:

• 2006/42/CE – Machinery Directive

• EN 1012-2:1996 – Compressors and vacuum

pumps – Safety Requirements – Part 1:

Compressors

SCOPE OF MANUAL

The scope of this manual and the Declaration of

Incorporation includes the bare shaft booster.

INTRODUCTION

01