Make sure the remote control is not off.

1. Make sure no crossing of connections of the receiver or damper took place, e.g. receiver

no. 1 was connected to inlet T1 and the damper is connected to inlet D2+ and D2-.

2. Make sure the connections of the receiver to the power supply box are orderly (see solution

no. 2).

3. If the connections were checked and were OK as detailed above, operate the damper with

the AUTO button on the receiver. If the damper reacts, check the batteries in the remote

control.

3. Checking the Proper Installation of the System

3.1.1 Connections

Ascertain:

- Receiver no. 1 (T1) is connected to entry no. 1 (T1) and motor no. 1 (T1) is connected to terminals D1 +, D1

›

- Receiver no. 2 (T2) is connected to entry no. 2 (T2) and motor no. 2 (T2) is connected to terminals D2 +, D2

›

- Receiver no. 3 (T3) is connected to entry no. 3 (T3) and motor no. 3 (T3) is connected to terminals D3 +, D3

›

- Receiver no. 4 (T4) is connected to entry no. 4 (T4) and motor no. 4 (T4) is connected to terminals D4 +, D4

›

- With the connection of the power supply box to line voltage ensure that the red indicator light on the power

supply box is on.

-Wait 70 seconds and switch the remote control off. Make sure that the damper is switched off (closed). In case

the damper is open, cross the two wires that reach the motor or the two wire connections +D and

›

D.

- Move between status 1/3 and 2/3 and make sure the damper actually moves.

3.1.2 Communication between Remote Control and Receiver.

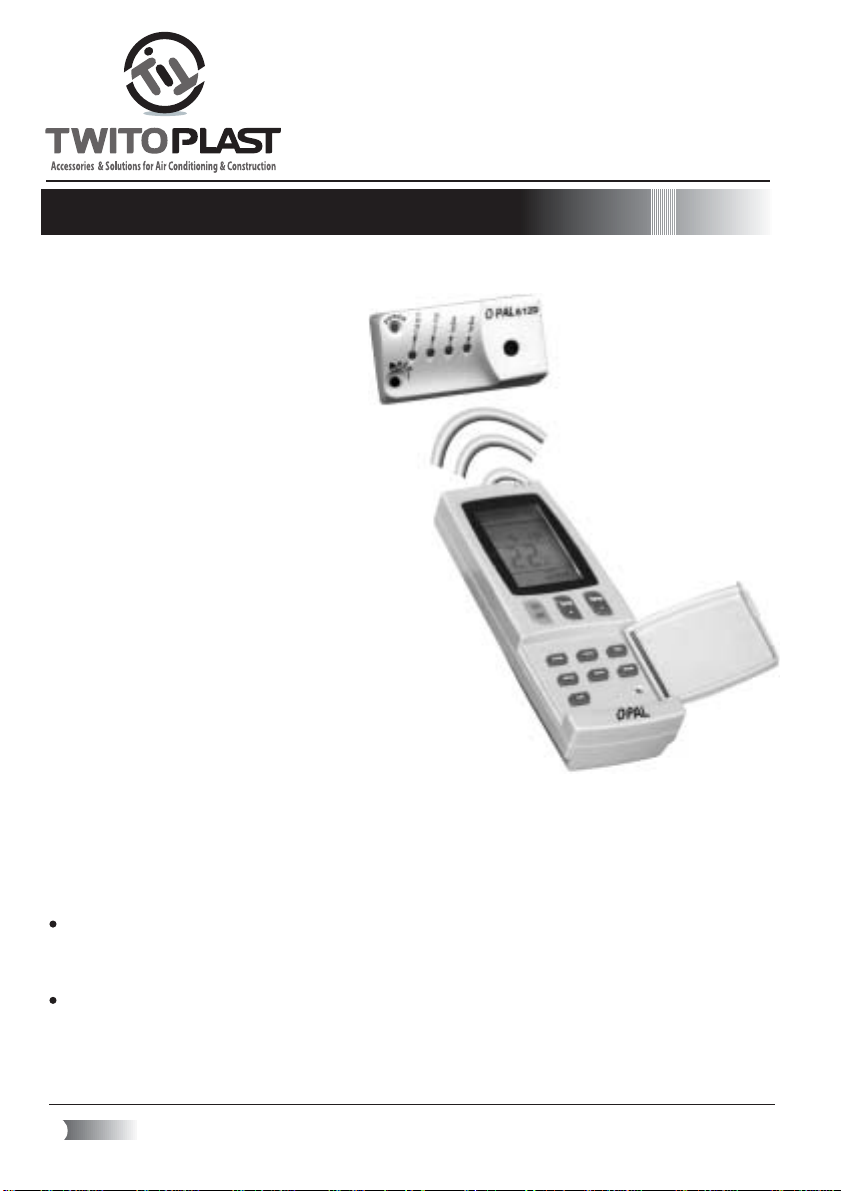

- When finishing the installation of the receiver and the holder of the Remote Control unit, try to activate the

receiver with the remote control when it is still in the holder.

- On the remote control press the ON button and check whether the red light on the receiver is blinking. The

blinking of the red on the Receiver informs that, the receiver absorbed the transmission from the remote control.

- In case there is no red light blinking on the receiver, change the required temperature on the remote control

and/or transfer the operational status from heating to cooling. Then check once again if the red lamp is blinking

in the receiver. If the receiver is not blinking, change the location of the remote control holder.

- Make sure to explain to the customer that the place for the remote control is in the holder unit. Keeping the

remote control in the holder, ensures the constant reception of reliable signals and enables a correct operation

of the system. In addition, this ensures the remote control will not be damaged.

3.2 Troubleshooting

Problem Solution

The indicator lamp on the

power supply box is not on

Check for 230 V electricity outlet.

1.Check that the connection of the power supply box to the 230v.

No ON/STBY indicator

on the receiver is alight.

The damper does not

react in spite of switching

from 1/3 to 2/3 and

changing the MODE

(heating / cooling)

1. Make sure that the snap connections are connected properly to the receiver and to the power

supply box.

2. Ensure that the indicator light in the power supply box is on, if not see solution to problem

6