GENERAL DESCRIPTION

Vari-Notch® duplexers are used to provide simulta-

neous operation of a transmitter and receiver (or

two transmitters) which are operating at different

frequencies while connected to a common an-

tenna. These duplexers are frequently used in ra-

dio repeater systems. This instruction manual

(part# 7-9177-1) covers the installation, tuning,

and maintenance of Vari-Notch duplexers con-

structed from 6.625" diameter cavities. Table 1

shows the model numbers and electrical specifica-

tions of the duplexers covered by this manual.

Vari-Notch duplexers are composed of two groups

(or sets) of daisy-chained resonant cavity filters,

which couple signals to and from the shared an-

tenna. This creates two signal paths, a high fre-

quency channel and a low frequency channel. The

minimum frequency separation between the chan-

nels, as well as the isolation in dB's (per channel

and between channels) is listed for each model in

table 1.

The cavity filters used in a transmit channel will

reduce transmitter noise components at the re-

ceive frequency, thus preventing noise desensiti-

zation of the receiver. Conversely, the cavity filters

used in a receive channel will isolate the receiver

from the transmitter carrier preventing carrier de-

sensitization of the receiver.

Resonant cavity filters are the basic building

blocks of the system. Also important, are the inter-

connect cables between each filter which have cut

length's equivalent to either 1/4λ or 3/4λ of that

channels pass frequency. The exception is the an-

tenna cable that couples each channels final filter

to the antenna port, which is cut to 1/2λof the

other (or remaining) channels pass frequency.

This effectively places a relatively large imped-

ance in parallel with the antenna, insuring a good

impedance match between the other (or remain-

ing) channel and the antenna. This technique of

impedance matching allows both channels to be

connected to the same antenna with very little loss

due to mismatching. The antenna cables are per-

manently soldered and crimped to the antenna

junction. The combination of the antenna junction

and the attached antenna cables is referred to as

an "Antenna Junction Assembly".

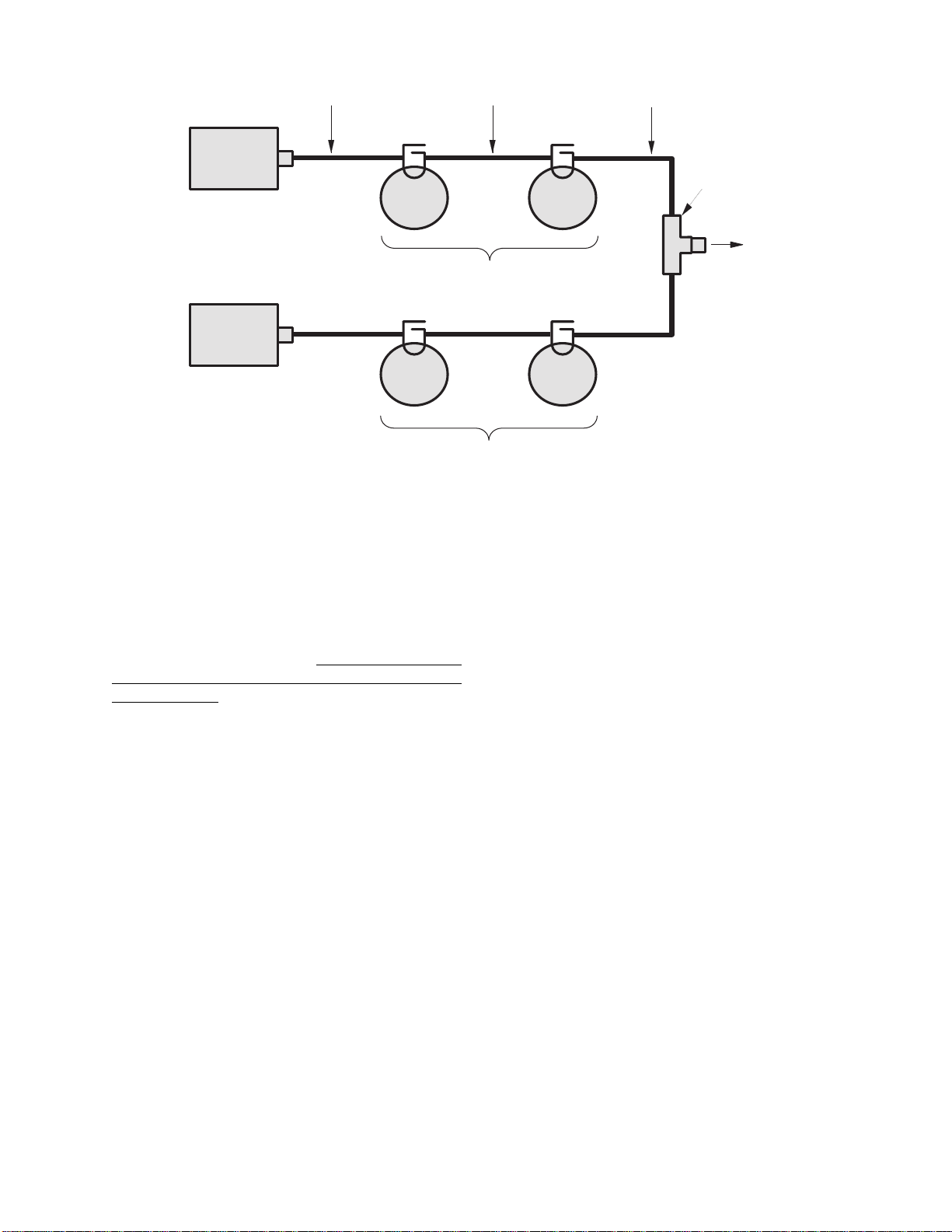

Figure 1 on page 2 shows the functional block dia-

gram of a typical four-cavity Vari-Notch duplexer

system. Six and eight cavity systems are similar

except for the extra filters in each channel. The

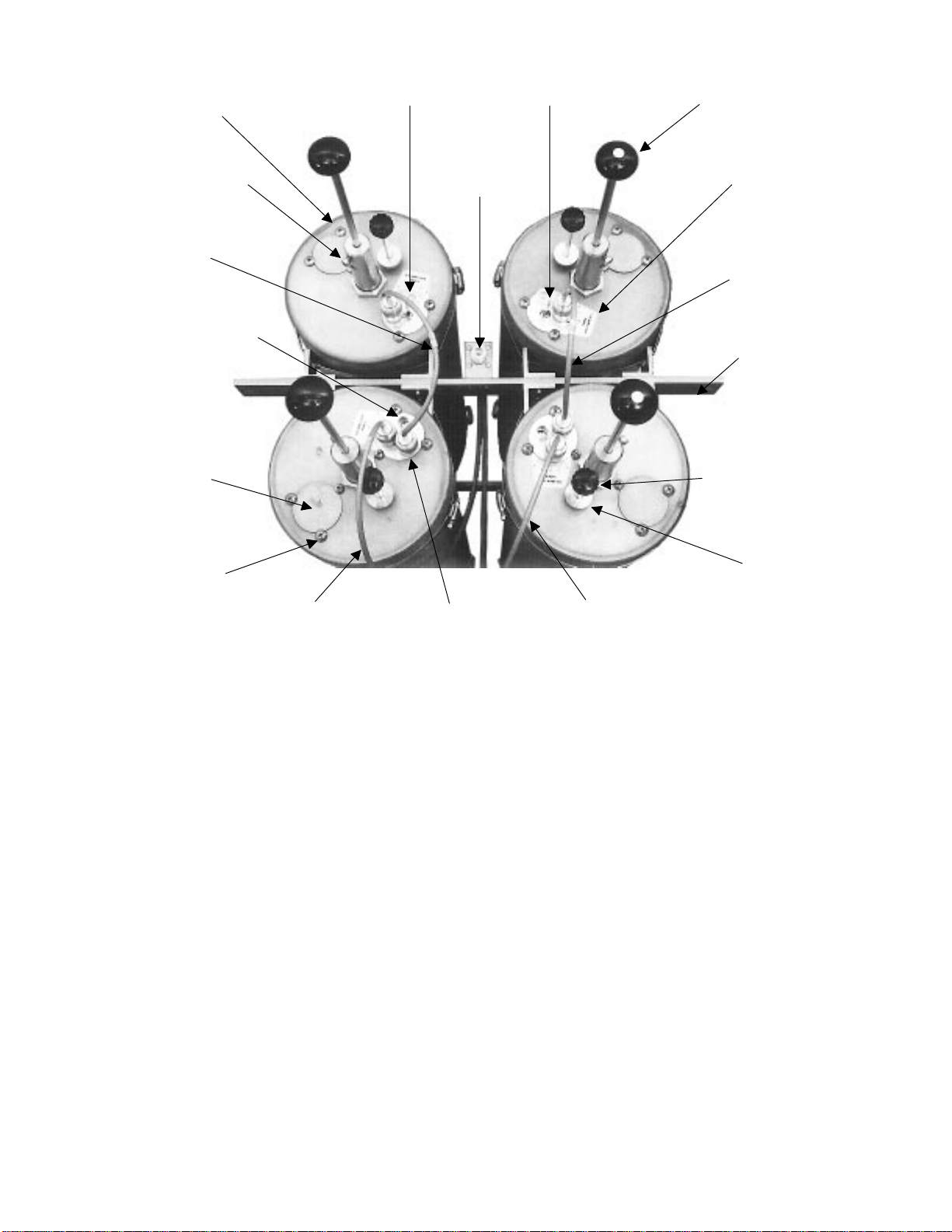

photograph shown in figure 2 on page 3 is the

front view of a typical four-cavity Vari-Notch du-

plexer. Each of the physical components in the

system is labeled with the field adjustable parts

shown in emboldened italics.

TX RX Systems Inc. Manual 7-9177-1 09/19/97 Page 1

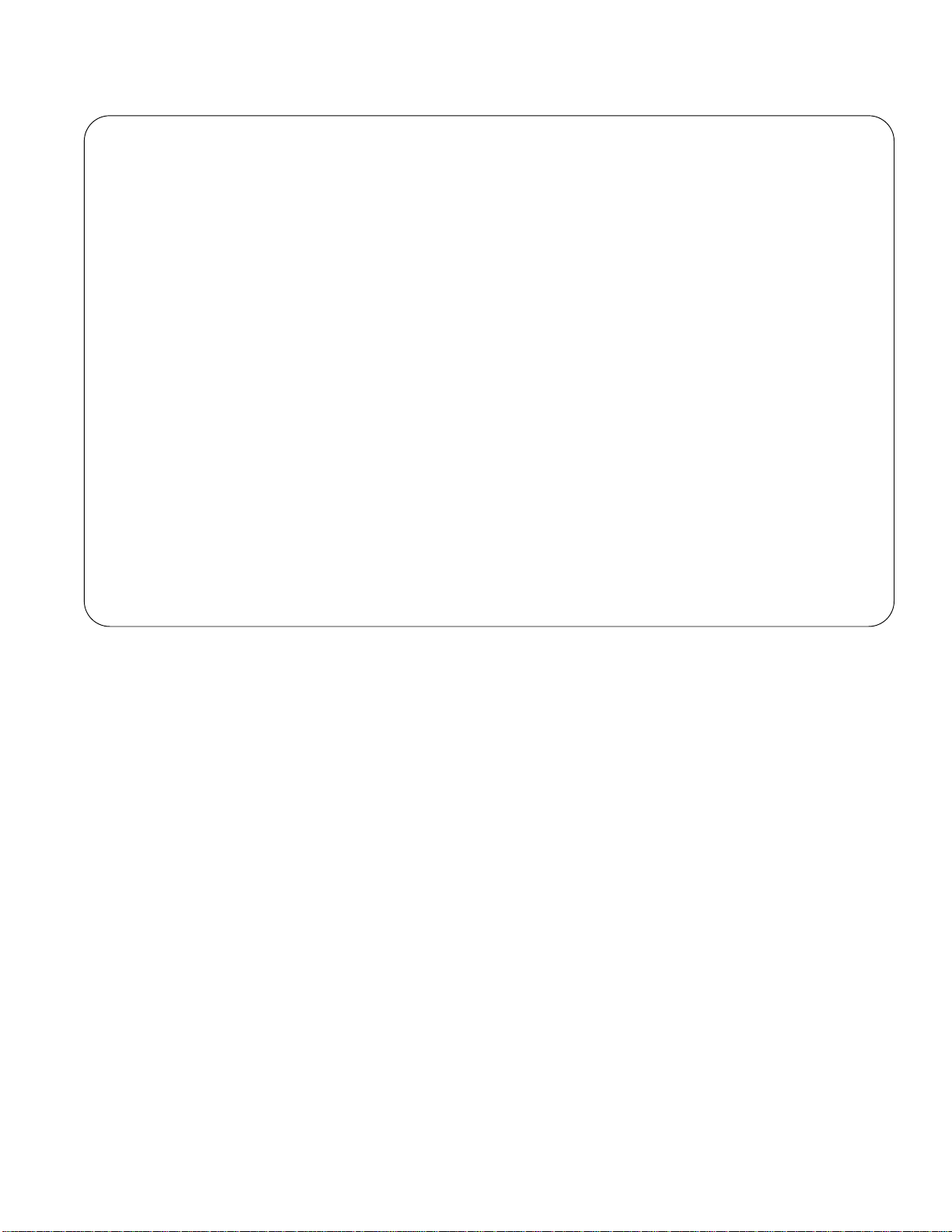

Model

Number Frequency Range

(MHz) Power

Rating

(Watts)

Min. Freq.

Separation

(MHz)

Insertion

Loss

(dB)

Isolation

(dB)

Per Chan. Bet Chan.

28-13-01F 30-40 400 0.3 1.5 90 50

28-14-01F 38-50 400 0.3 1.5 90 50

28-28-02A/G 66-88 400 0.35 1.5 85 50

28-36-02A/G 132-150 400 0.5 1.5 85 50

28-36-11E/G 132-150 400 0.3 2.2 100 50

28-37-02A/G 144-174 400 0.5 1.5 85 50

28-37-11E/G 144-174 400 0.3 2.2 100 50

28-37-08G 144-174 400 0.24 3 100 50

28-65-01A 406-430 350 1.5 1.5 90 50

28-65-05A/G 406-430 350 0.7 2.2 100 50

28-70-01A 450-470 350 1.5 1.5 90 50

28-70-07A/G 450-470 350 0.7 2.2 100 50

28-69-01A 470-512 350 1.5 1.5 90 50

28-69-04A 470-512 350 0.7 2.2 100 50

Table 1: Vari-Notch Duplexer electrical specifications (for 6.625" diameter cavities).