Contents Page

1.0 General 1 - 2

2.0 Unpacking 2

3.0 Installation 3 - 6

3.1 Safety Information 3

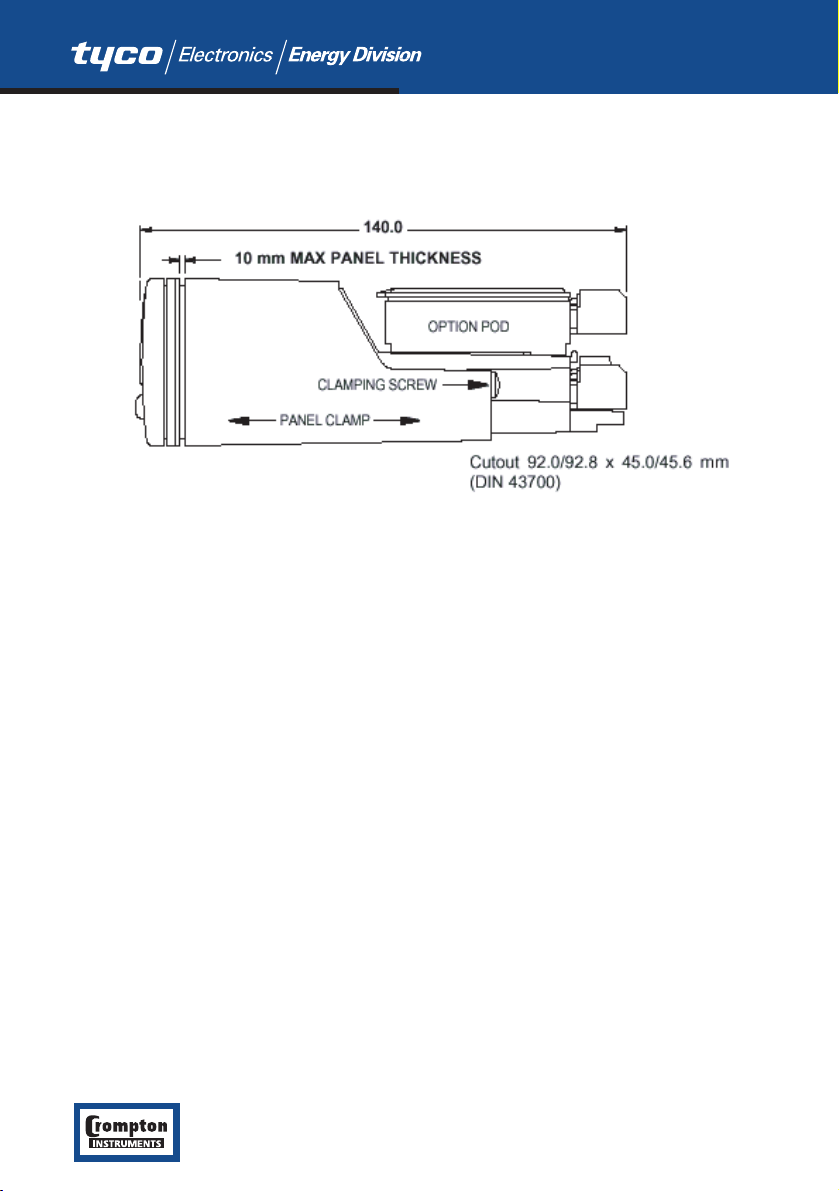

3.2 nstalling Into a Panel 4

3.3 Wiring 4

3.4 Power Supply 4 - 5

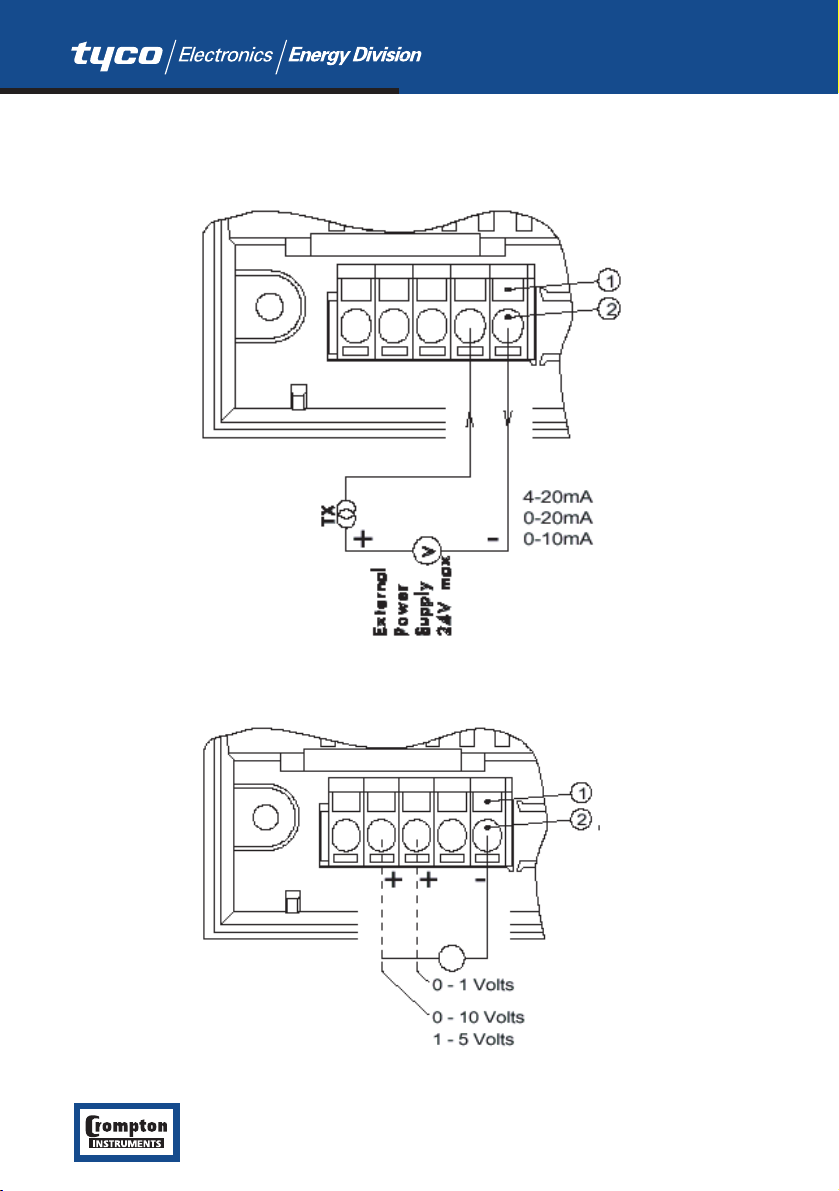

3.5 Sensor Connections 5

3.5.1 Current Measurement of an 5

Internally Powered Loop

3.5.2 Current Measurement of an Externally 6

Powered Loop

3.5.3 Voltage Connection 6

4.0 Programming the Instrument 7 - 10

4.1 Programming Guide 7

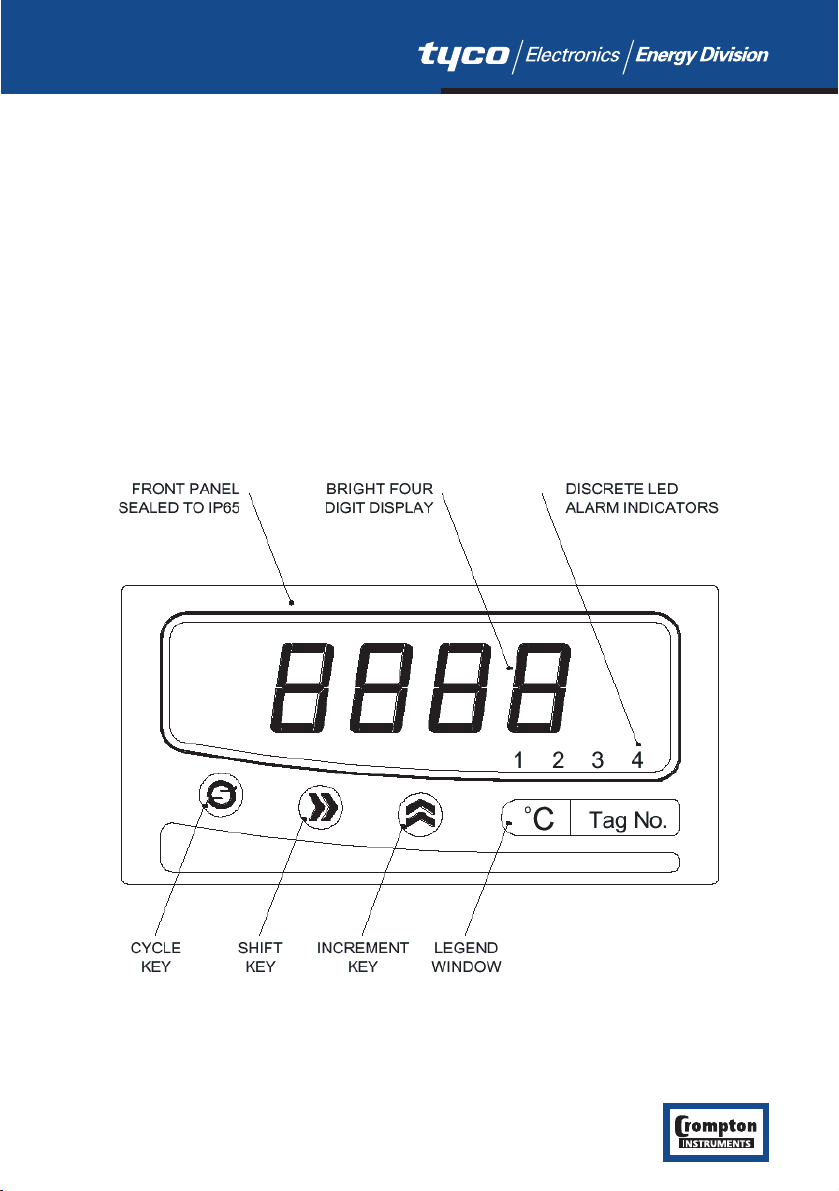

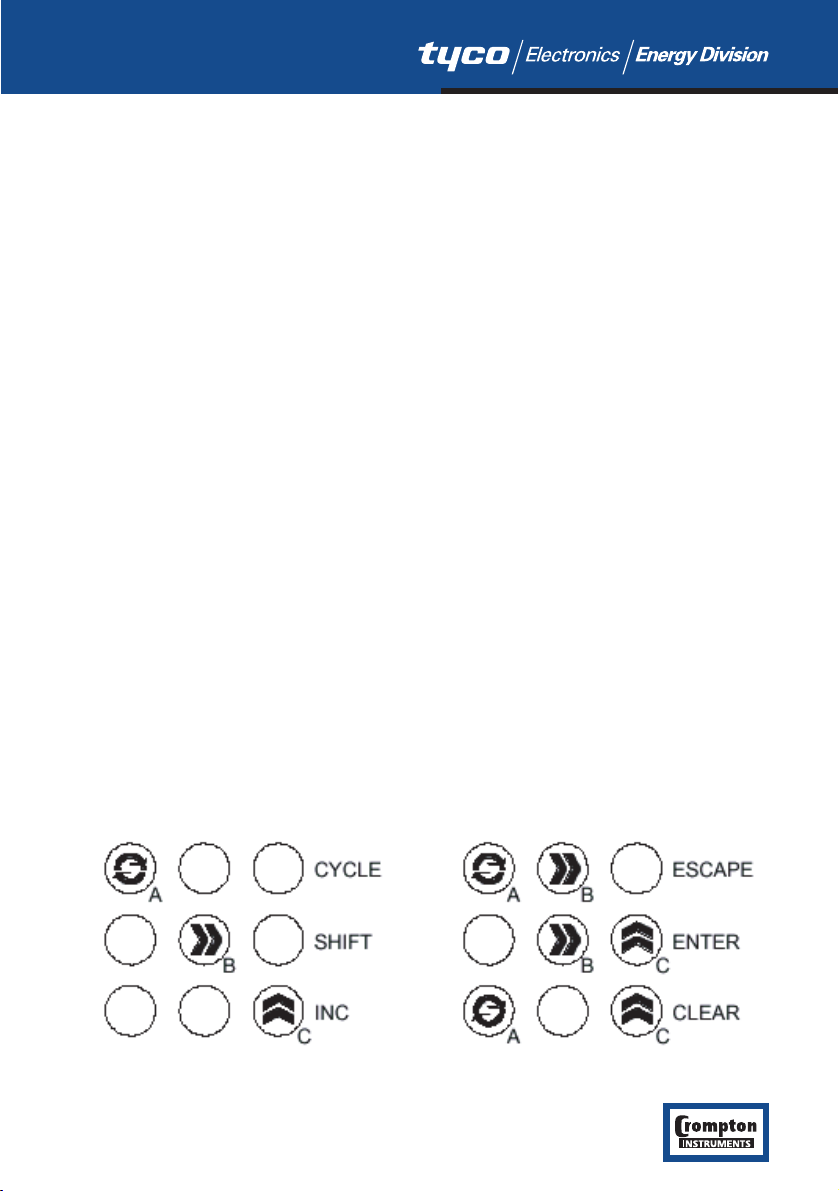

4.2 Key Definitions 7

4.3 Entering Menu Mode 8

4.3.1 Moving Around The Menu 8

4.3.2 Entering A Submenu 8

4.3.3 Editing A Parameter 9

4.3.4 Returning From Submenus 9

4.4 The Menus

4.4.1 The INPt (INPUT) Submenu 10

4.4.2 The SyS (System) Submenu 10

5.0 Operation 11

5.1 Run Mode Operation 11

5.2 Failure Modes 11

6.0 Specification 11

6.1 Process Specification 11

6.2 General Specification 11 - 12

7.0 Option Modules 12 - 16

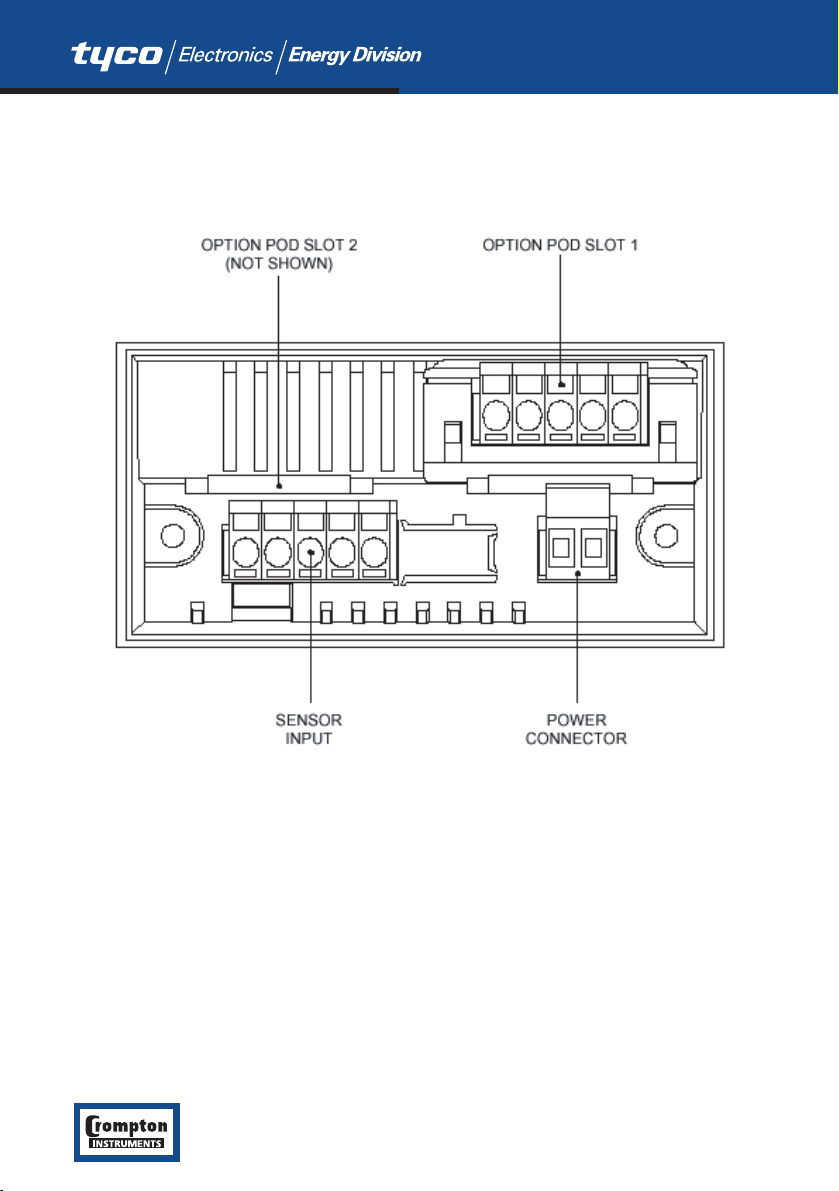

7.0.1 Installing Modules 12

7.1 262-RLY Dual Relay Module 13

7.1.1 SLT1, SLT2 (Relay Module) Submenu 13

7.1.2 Relay Specification 13

7.2 2 62-ALG, Isolated Analogue Output Module 14

7.2.1 SLT1, SLT2 (Analogue output 14

module) Submenu

7.2.2 Analogue output module Specification 14

7.3 Modbus Serial Communications Module, 15

262-MOD

7.3.1 SLT1, SLT2 (Communications) Submenu 15

7.3.2 Comms Module Specification 15 - 16

8.0 Mechanical Detail 17