5BI

R

+

-

L2

L

-

+

TYCO

MX c.i.e.

AL

AR

L1

TYCO

E500Mk2

REMOTE

INDICATOR

R

LL1

L2

M

R

L

L1

L2

R

L

M

L1

L2

R

L2

LL1

M

R

L

L1

L2

5BI5B

M

M

5B

R

L

R

L

M

L1

L2

L1

L2

-

+

DETECTOR ADDRESS

The address label carrier is fitted to the detector before mounting on the

base. When the detector is mounted to the base, and turned clockwise

until fully located on the base, the address label carrier is transferred to

the base. If the detector is removed the address label carrier remains on

the base.

Part Number Desc.

516.800.915 Label Carrier

516.800.931 White Label

516.800.932 Yellow Label

516.800.933 Purple Label

516.800.934 Green Label

www.tycosafetyproducts-anz.com

Tyco Safety Products, a division of Tyco Australia Pty Limited

A.B.N. 80 008 399 004, reserve the right to alter specifications without

notice, in line with Tyco’s policy of continuing product improvement.

INSTALLATION

The 814 series of detectors are not suitable for use where they may

be exposed to condensing moisture, mist or water spray.

When mounting on a damp surface or narrow beams where

condensation may enter the rear of the detector, the deckhead

mounting base DHM5B (part no. 517.050.603) or similar should

be used. The 814CH should not be positioned where high localised

levels of CO may normally occur, e.g. indoor car parks, warehouses.

The 814H Heat detector may be more appropriate. Installation of all

detectors should be carried out in accordance with AS 1670.1/

NZS 4512. Cable penetrations should be sealed when positive or

negative pressures in ceiling spaces may affect the performance or

contaminate the installed detectors.

MAINTENANCE AND SERVICE

The Tyco MX addressable system should be maintained in accordance

with AS 1851/NZS 4512. The Tyco X300 Smoke Tester, X461

Heat Tester and CO Test Gas (part no. 517.001.262) may be used for

testing in-situ. Rotating the detector anticlockwise past an indent to

the park position disconnects the detector from the circuit whilst still

retaining it in the base, allowing wiring testing etc. Note that insulation

testing must not be done when isolator bases are used.

Depressing the plunger at the side of the base allows the detector to

be rotated back into its operating position. Wormald Detector Clean &

Calibrate Wollongong are able to check the calibration of MX detectors.

Additionally, although the 814CH has an expected life in excess of

10 years, in order for the 814CH to provide the intended level of fire

detection, the detector should be checked for calibration 5 years after

installation or within 7 years of the date of manufacture.

Applications Warning In many fires, hazardous levels of smoke

and toxic gas can build up before a heat detection device will initiate

an alarm. In cases where life safety is a factor, the use of smoke

and/or CO detection is highly recommended. Heat detectors are not

considered to provide life safety protection and are generally used

where property protection is desired, but smoke or CO detectors cannot

be used. Typical heat detector applications are satisfied by the use of

rate-of-rise and fixed temperature electronic detectors. The addition

of rate-of-rise operation provides faster heat detection for use where

temperature fluctuations are controlled and less than 6°C/min. Where

temperatures may fluctuate more quickly, use fixed temperature

detection only (Type B or Type D).

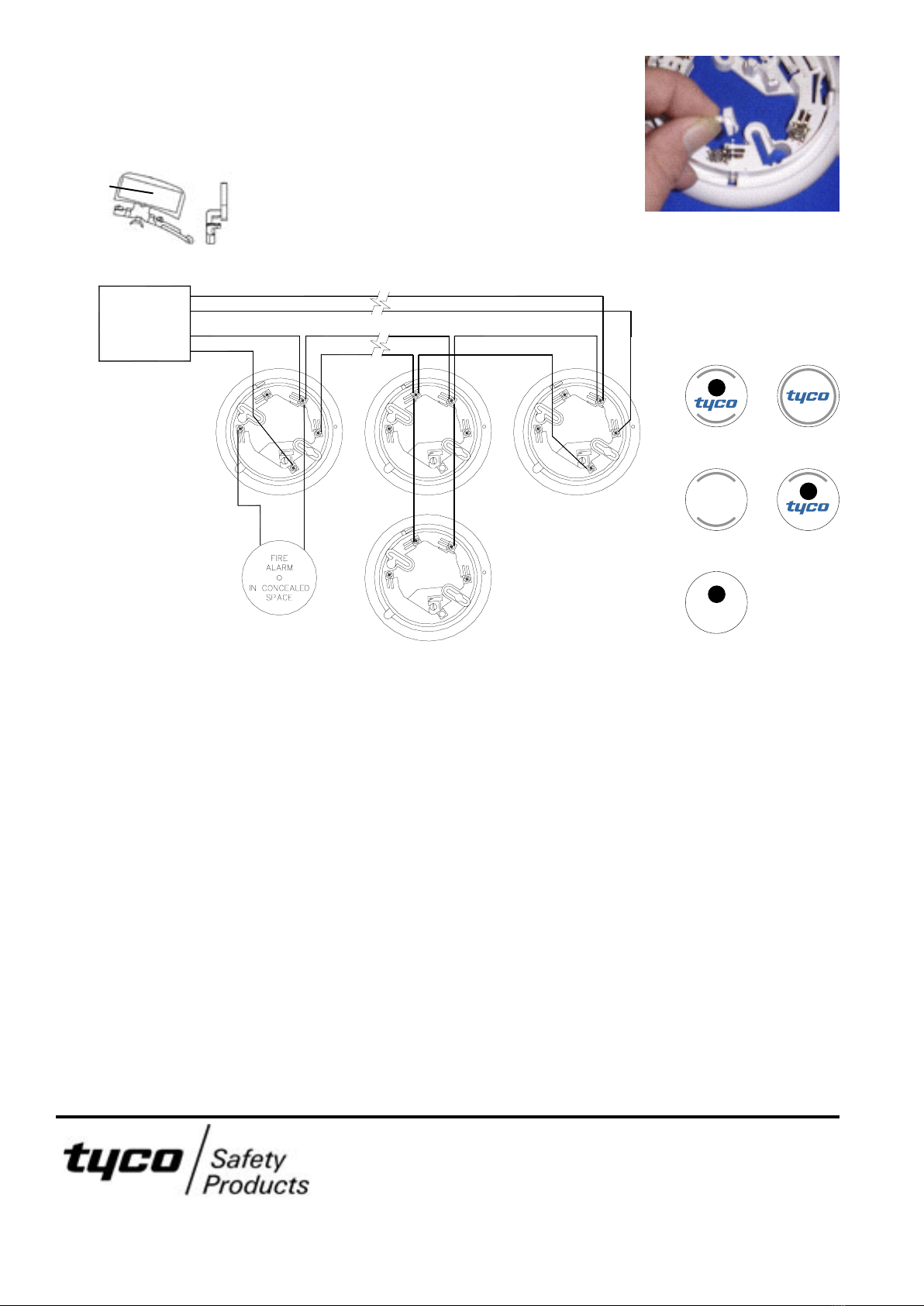

All wiring terminates at the 5B or 5BI base as follows:

R: – Remote L: – In and Out L1: + In, Out & Remote M: – In (5BI only) L2: – Out (5BI only)

Cables should be arranged at each side of the terminal screw. A maximum of two 1.5mm2 cables or one 2.5mm2 cable can

be fitted to one terminal. Any additional cables (such as Remote Indicator) should be fitted with suitable fork or eyelet crimp

terminal lugs. The installation should comply with AS 1670.1/NZS 4512.

Note that alarm zone circuits with more than 40 devices must be wired as a loop and use isolator bases in accordance

with the design manuals. Refer to the relevant information sheet for base wiring details.

LOCKING KEY

A detector locking device is

moulded into the 5B base. This

must be detached and inserted

into the locking aperture if

required, prior to the selected

detector being installed. The

detector may then be removed

only by inserting an unlocking tool

(a Ø3 x 22mm long rod) into the

hole on the detector cover to depress the locking device.

5 June 2009

120.415.744 Issue 13 ©Tyco Safety Products - Fire Detection - ANZ Region Page 2 of 2

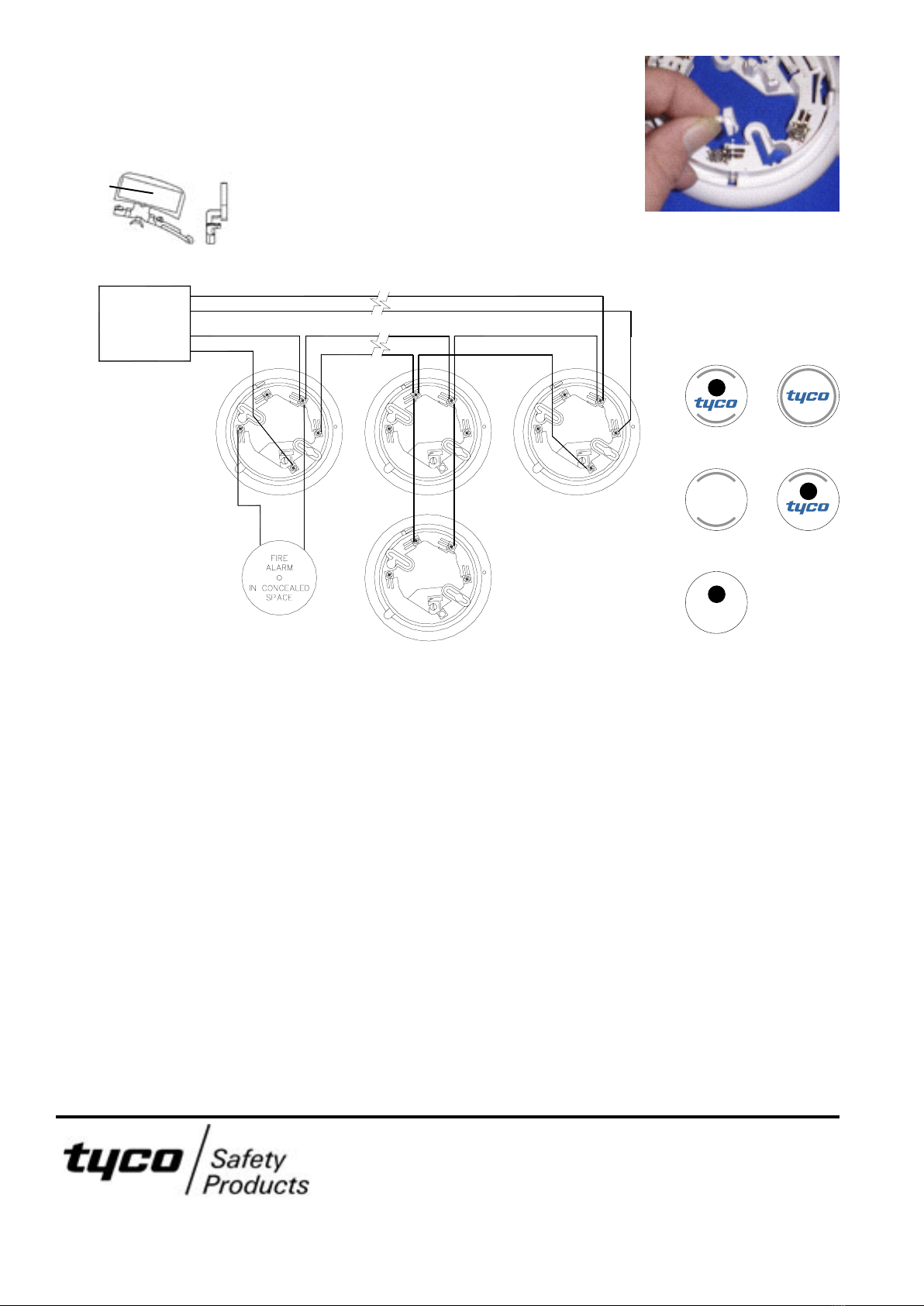

WIRING

tyco

814PH 814I

814P 814CH

814H

DETECTOR

IDENTIFICATION

Each detector is identified

by a unique label on the

top, as shown:

The MX c.i.e. can

be programmed to

illuminate a Remote

Indicator for detectors

other than the detec-

tor base to which it is

connected.

tyco

ADDRESS

FLAG

AFFIXED

HERE