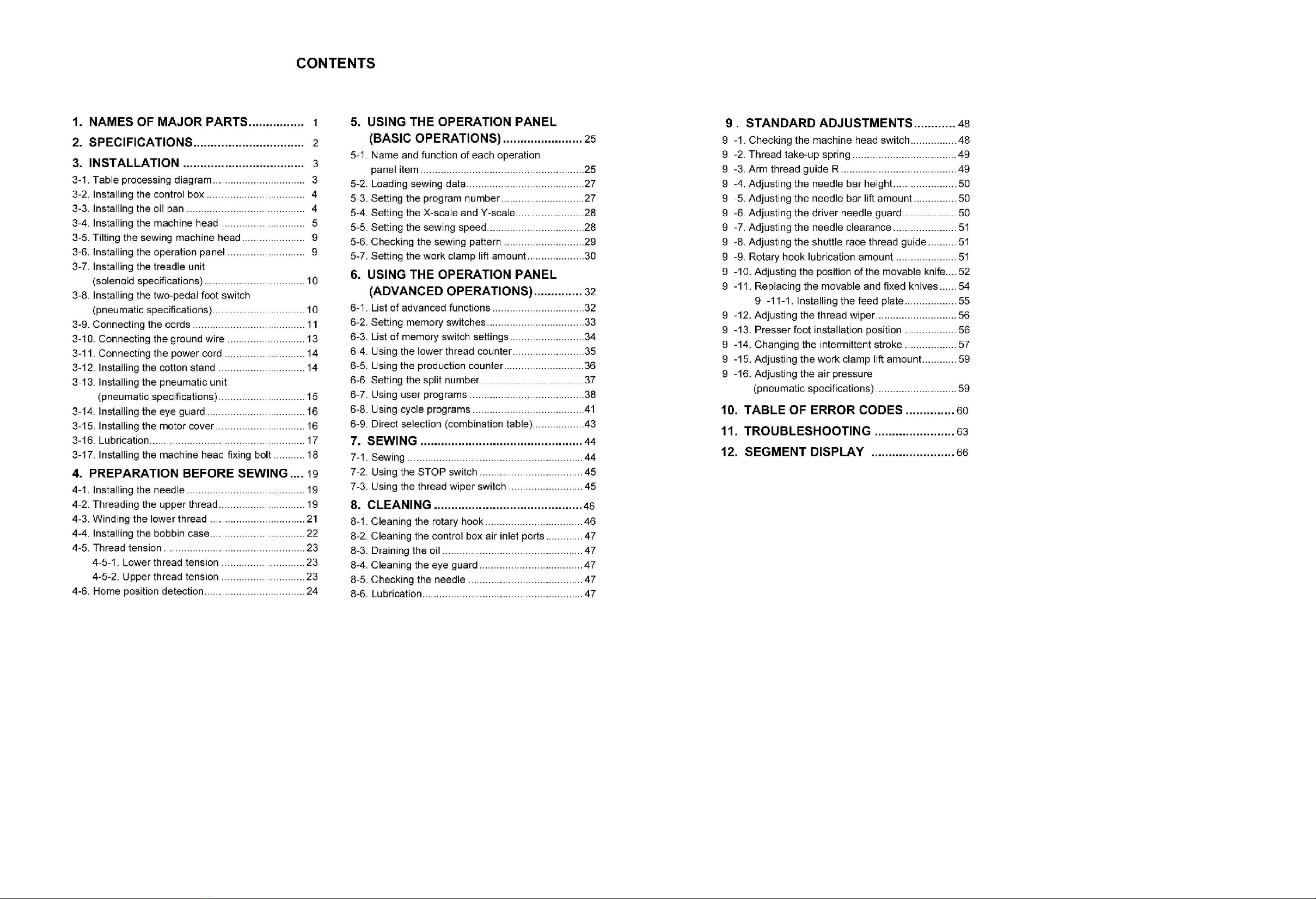

CONTENTS

1.

NAMES OF MAJOR PARTS................

2. SPECIFICATIONS................................ 2

3. INSTALLATION ................................... 3

3-1. Table processing diagram

..

o..o

....

....0......o....

00

00 00

3

3-20

lnstalling the control box 0

0000

.00

00

.o

...

0

..

·o·

..

o

.o.

0

....

o.

4

3-3. lnstalling the oil pan

....

0

00

000000

oooo

o

..

..o

......

o

..

..o

....

o.

4

3-40

lnstalling the machine head ......

o....

....

..

....

..

...... 5

3-50

Tilting the sewing machine head

..

..

..

..

o

..

o

..

..

....

..

9

3-60

lnstalling the operation panel

..

0......0

..

o....

..

..

0

000..

9

3-70lnstalling the Ireadle unit

(solenoid specifications)

....

o

..

0..........0

..

....

..

0

..

o.... 10

3-80

lnstalling the two-pedal foot switch

(pneumatic specifications)o

....

..........

..

o

..

o

oo

o........ 10

3-90

Connecting the cords

..

o....o

....

..

..

o

..

o

..

..

o....

..

o

..

o....

11

3-100Connecting the ground wire o

..

o

..

..

o

..

o

.. ....

..

o

..

o

..

o13

3-11. Connecting the power cord o....o

..

..

o

..

o....

..

..

o

..

o

..

14

3-120lnstalling the cottonstand

..

0....

..

....

..

0

..

..........

..

14

3-130lnstalling the pneumatic unit

(pneumatic specifications)

..

0....0o....

..

0

..

0

..

0

..

....

..

15

3-140lnstalling the eye guard

..

0

....

....

..

......

..

....

0

..

....

..

16

3-150lnstalling the motor cover

..

..

....o

..

o....o....o

....

o....

16

3-160Lubrication

..

o.......o..........

..

o

..

o....o......o....o.......... 17

3-170lnstalling the machine head fixing bolt 0

..

..

...... 18

4.

PREPARATION BEFORE SEWING .... 19

4-1

0lnstalling the needle ..........o

..

o....o............o

..

o......

19

4-20

Threading the upper thread

..

o....o

..

o....o....o

....

..

o

..

19

4-30

Winding the lower thread o....0

000

.........0..............

21

4-40

lnstalling the bobbin case

..

o

..

o......

..

..

..

0............

..

22

4-50Thread tension

..

0..................0....0........0......

..

..

0

..

23

4-5-1 0Lower thread tension ......o....o

..

o....o........o23

4-5-20

Upperthread tension ......o

..

..

..

..

..

o

..

..

o

..

.... 23

4-60

Home position detection0..................

..

o

..

o

..

....

....

24

5. USING THE OPERATION PANEL

(BASIC OPERATIONS) .......................25

5-1. Name and function

of

each operation

panel item

...

..

00

..

0.....

..

.0

....

.......0

..

o.........

..

0......0....25

5-2. Loading sewi

ng

data

..

..

......

..

..

..

o....o

..

ooo

....o

..

......o27

5-3.Setting the progr

am

number............o

..

......o.......27

5-4. Setting the X-scale and Y-scal

eo

........

..

......

..

oooo

o28

5-5. Setting the sewing speed

..

o

..

..

..

......

..

..........

..

..

..

028

5-6. Checking the sew

in

g pattern

..

....

..

o

..

o......

..

o......o29

5-7. Setting the wo

rk

clamp

Ii

ft amount..........o

....

..

..

o3

0

6. USING THE OPERATION PANEL

(ADVANCED OPERATIONS)..............

32

6-1

. List ofadvanced functions 0

..

..

..

0....0

..

0

..

....

..

0

..

..

..

0

32

6-2. Setting memory switches

..

0

..

..

..

..........

..

..

..

....

00

..

03

3

6-3. List of memo

ry

sw

itch settings

..

0......0......

..

0

..

00

..

0

34

6-4. Using the lower thread counter........o

..

..

....o

..

ooooo3

5

6-5. Using the production counter

....

o

..

....

o

..

..

oo

..

o....o

..

36

6-6. Setting the

spl

it numbero

..

....

o

..

..

oo

..

oooo

..

..

o

..

..

....

..

o3

7

6-7. Using user pr

og

rams

..

..

o

..

oooo

..

..

o

..

..o....

..

0....0

..

00

00

03

8

6-8. Using cycle programs....

..

................0

..

..

....0

..

00000

41

6-9. Direct selection (combination table)

..

..

....

..

o

..

oo

oo

o43

7. SEWING ...............................................44

7-1. Sewing o

..

..

....

....

..

..

o....o

..

....o....o......o........o....

..

o

..

o44

7-2. Using the STOP switch

..

..

0....0......

..

..

..

o

..

0

..

..

0

....

045

7-3. Using the thread wiper switch ......

..

..

......

....

0

....

.45

8. CLEANING ...........................................46

8-1. Cleaning the rotary hook..................0....0

..

..

..

0

..

046

8-2. Cleaning the control box air inlet ports

..

000

..

0

....

.4

7

8-3. Draining the o

il

..

0

..

..

..

........

000

....

..

0

..

..

..

o....0

..

....0

..

.47

8·4. Cleaning the eye guard ........

..

....

..

..

..

0......

..

0

..

0

00.4

7

8-5. Checking the needle

..

......

000

..

o....

....

..

o

..

..

000

..

..

0

..

.47

8-6. Lubricationo

...

....

00

..

o

..

0

....

00

..

o

..

0

....

.0

..

o

...

..

o

..

....o

..

000

047

9.

STANDARD ADJUSTMENTS............ 48

9

-10

Checking

th

e ma

ch

ine

he

ad

sw

itch

..

..

00

..

00

000000

48

9 -20Thread take-up spring

..

..

o

..

..

..

..

............

..

......

..

049

9 -

30

Arm thread guide R 0

00

..

....

..

..

..

..

........0

00

0

..

00

..

0

00

..

49

9

-40

Adjusting the nee

dl

e bar height..

..

..

....

00

..

00

0000

00

50

9 -50Adjusting the needle bar

Ii

ft

am

ount............... 50

9 -

60

Adjusting the driver needle guard....o

..

oo oo

....

..

..

50

9 -

70

Adjusting the needle clearanceoo

..

oo

....

..

..

oo

....

oo51

9 -

80

Adjusting the shuttle race thread guide

..

..

....

..

51

9 -90Rotary hook lubrication

am

ount o............

..

......

51

9

-100

Adjust

ing

t

he

position o

fth

e mova

bl

e

kn

ife

..

oo

52

9

-110

Replacing the movable and

fi

xed knives

....

oo

54

9 -11-1. lnstalling the feed plateo

..

o.............. 55

9

-120

Adjusting the thread wiper....o........o

..

o......0.... 56

9

-1

30Presser foot installation position ..

....

............ 56

9

·140

Changing the intermittent stroke ..........

..

...... 57

9

-150

Adjusting the work clamp Iift amount..

..

00

...... 59

9

-160

Adjusting the air press

ur

e

(pneumatic sp

ec

ifications)

..

..

o

..

......o

..

o

..

....0.... 59

10. TABLE OF ERROR CODES ..............60

11. TROUBLESHOOTING .......................63

12. SEGMENT DISPLAY ........................66