1 Important notes

EN Floor grinding machine FGE 530

5

1 Important notes

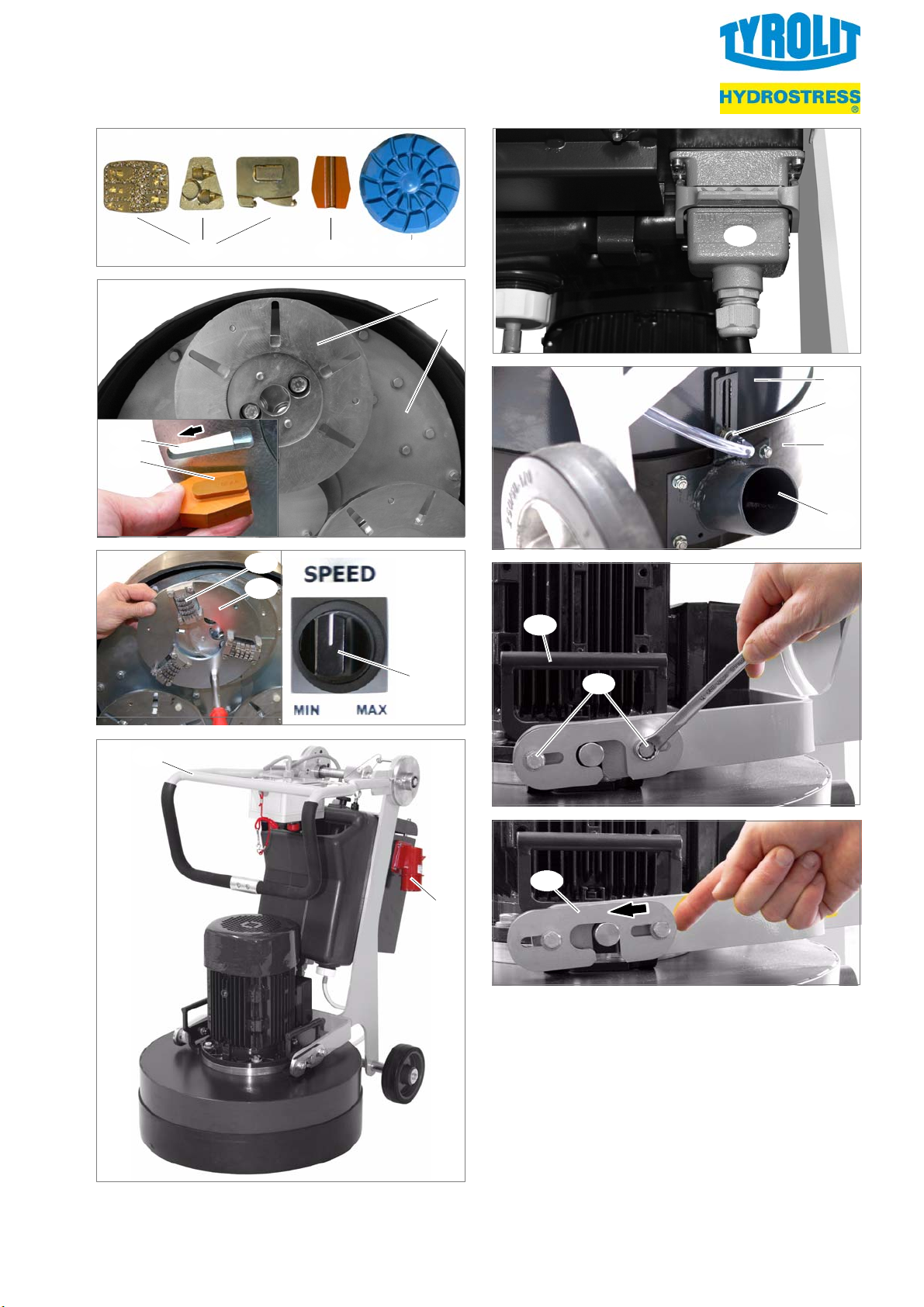

The machine may be used only with the accessories

supplied by the manufacturer for stripping, wet and

dry grinding of floor surfaces such as:

—cement

—screeds

—synthetic resin screed / asphalt

—natural stone floors

—remnants of adhesive or filling compound

—floor remnants (e.g. foam backing)

Any other use of the machine can lead to dangerous

situations and is prohibited!

To ensure correct use of the machine, follow the in

structions in the operating manual, paying particular

attention to any warnings and instructions relating to

operation and maintenance!

Before using the machine, the opera

ting personnel must carefully read and

understand this operating manual!

Keep this operating manual close at

hand for easy reference!

Read and observe documents and operating manuals

provided by suppliers!

If the machine is on loan to other parties, the opera

ting manual needs to be provided with the machine

and its importance must be made clear!

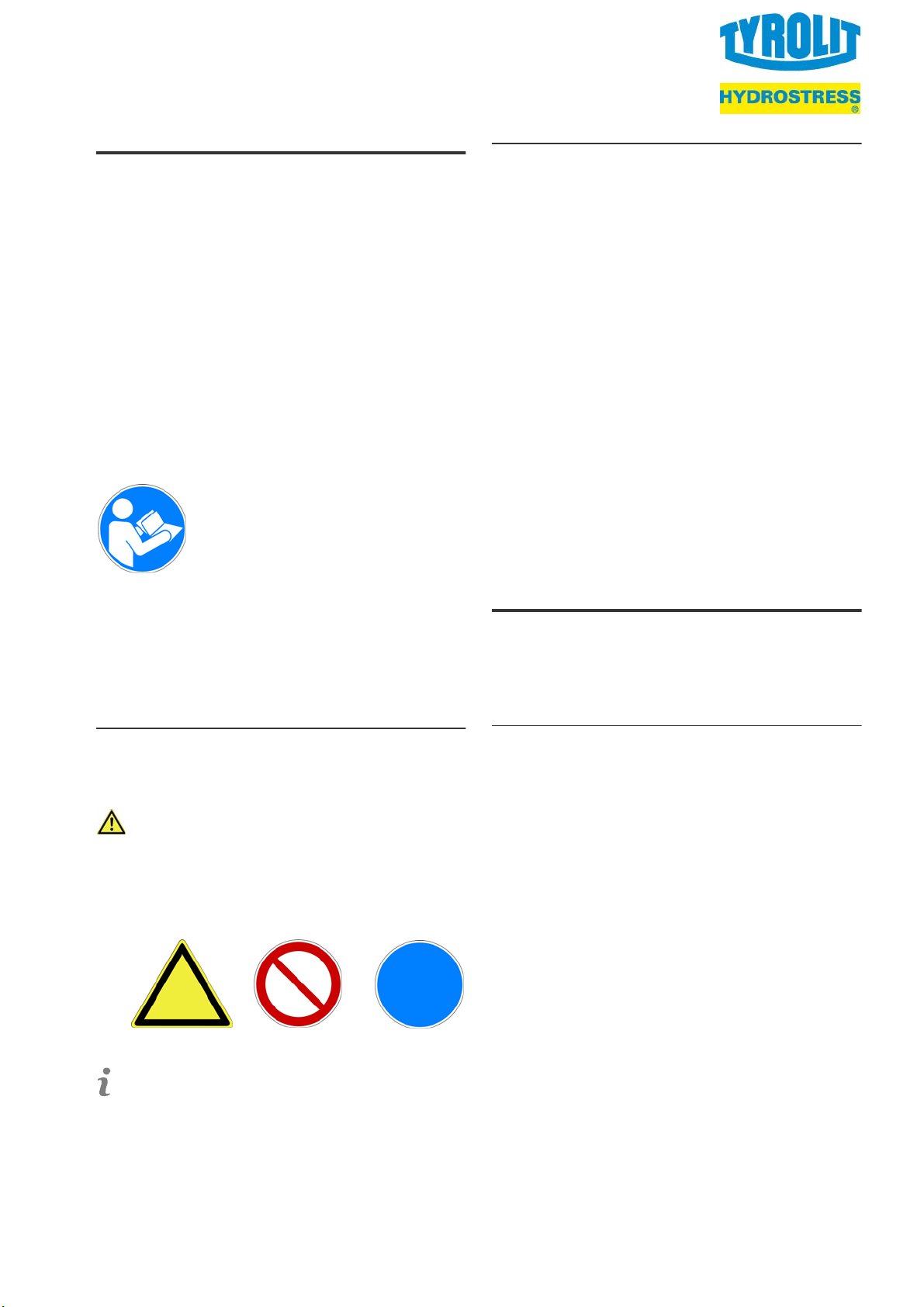

1.1 Symbols used

The following symbols are used in this

documentation:

Safety instructions

This symbol indicates warnings, prohibitions and

instructions regarding potential hazards. These

instructions must be obeyed and closely

observed.

Some safety instructions are accompanied by

appropriate symbols.

Additional information

This symbol indicates additional information.

1.2 Liability and warranty

TYROLIT Hydrostress AG

All rights, including those pertaining to translation, lie

with TYROLIT Hydrostress AG.

Liability or warranty is excluded if:

—The instructions in the operating manual have not

been observed.

—The machine or its attachments were improperly

operated.

—The maintenance was carried out inadequately or

incorrectly.

—Specified spare parts were not used.

—The protective guards were not used, have been

altered or were removed.

—The specified power supply ratings and surroun

ding conditions have not been observed.

The manufacturer is not liable for any damage that

may result if the user makes any changes to the ma

chine without the manufacturer's permission. Any

such actions will also void the warranty.

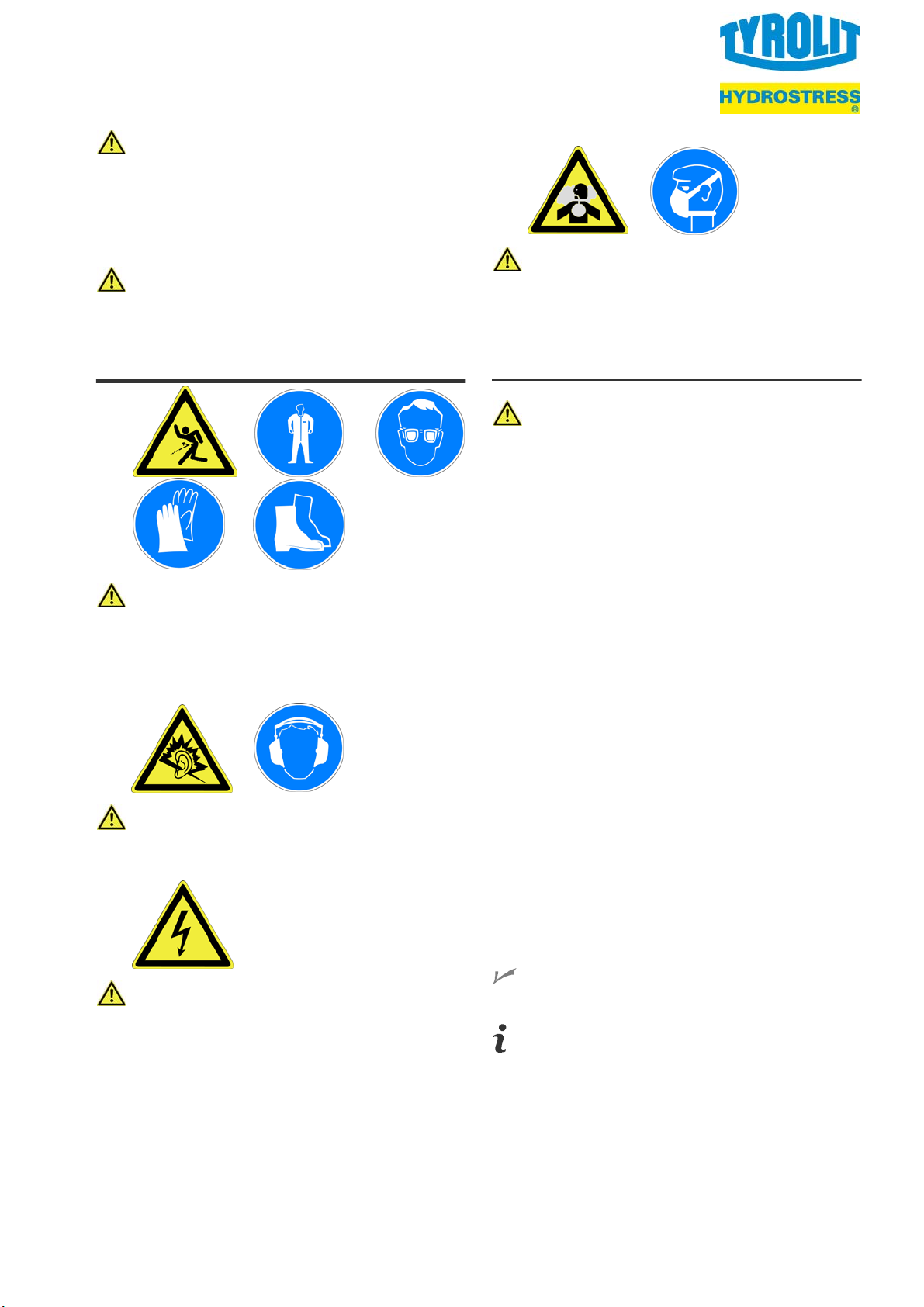

2 Safety

This chapter contains a summary of the most impor

tant information on safety when handling the ma

chine.

2.1 Accident prevention and safety

The following instructions comply with legislation, di

rectives, and publications including:

—EC Machinery Directive

—EC General Product Safety Directive

—Law governing technical materials

—Law governing equipment safety

—Law governing product liability

This operating manual is intended for operators and

tool setters, as well as for the personnel that service,

maintain and repair the machine. Together with all

the technical documentation, it is intended to help

—avoid hazardous situations

—use the machine for its intended applications

—avoid downtime and repair costs

—maintain the function of the machine

—extend the service life of the machine.

The manufacturer and owner of the machine must

respect the contents and regulations of the EC direc

tives. The effectiveness of any measure ultimately

depends on how well all parties, i.e. the manufactu

rer, the owner and the machine operators, work toge

ther to uphold safety standards.

Warning Prohibition Direction