sAfety 7

Residual risks

There is a risk of severe injury resulting from the residual risks described below.

Grinding tools ying away

• Only start grinding when there are no other persons in the danger zone.

• Make sure that a safety distance is complied with.

• If grinding tools are damaged, change them.

• Grinding without a protection cover is prohibited.

Uncontrolled movements and vibrations

• Do not connect or disconnect cables when the oor grinder is running.

Getting trapped and caught

Items of clothing or long hair could be caught by the rotating cutting tool.

• Do not wear loose clothing when working.

• Secure long hair in a hair net.

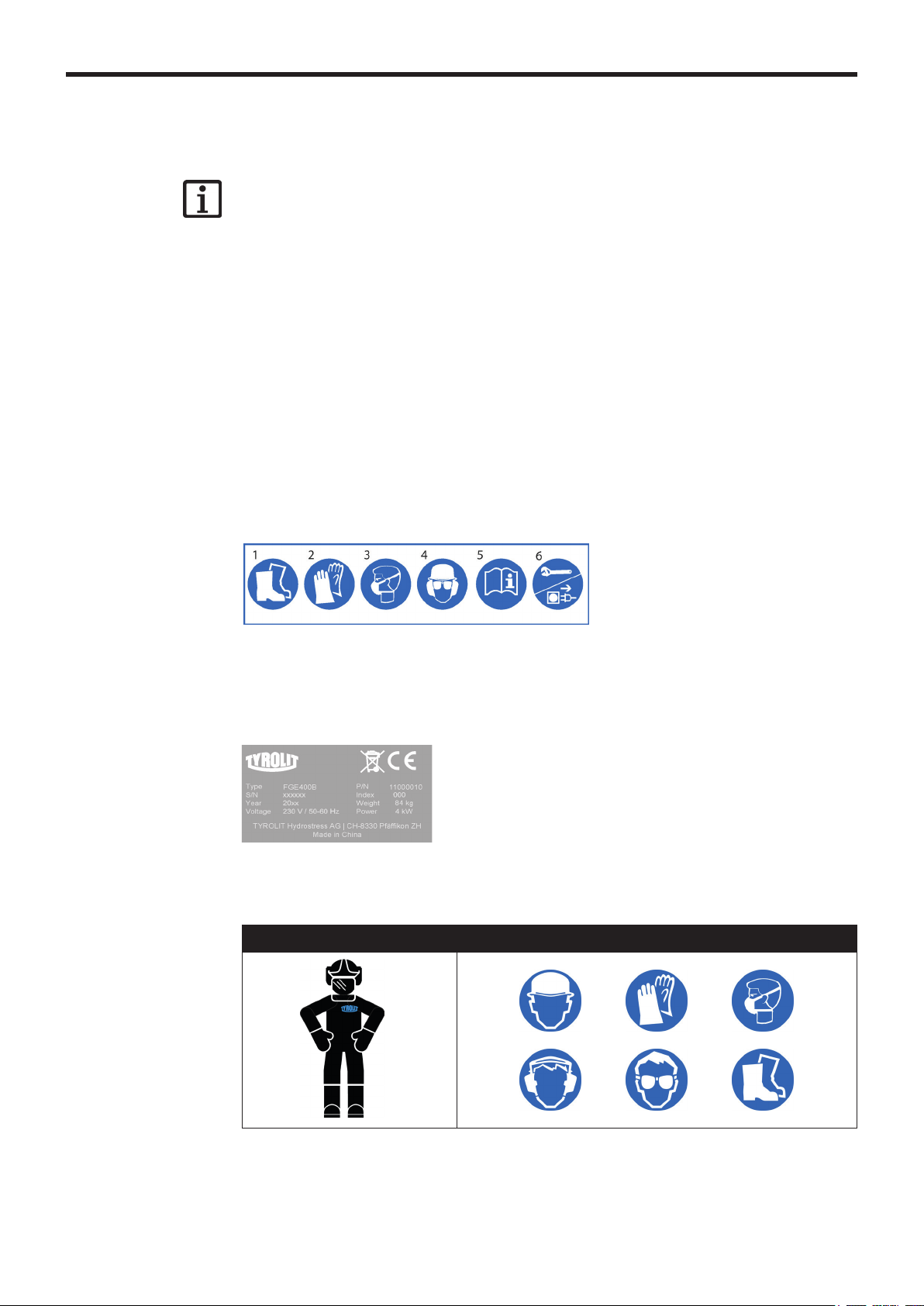

Harmful dust

Inhaling dust can lead to respiratory problems.

Inhaling dust emanating from the machine is hazardous to health.

• Wear a respirator mask.

• Make sure that closed rooms have adequate ventilation.

• Use a dust extractor during work.

Poor physical condition

• Do not work under the inuence of alcohol, drugs or medication.

• Do not work when overtired.

Tool quality

• Do not use damaged grinding tools.

• Check grinding tools for damage before assembly.

Danger from a grinding tool continuing to run in an accident

• Make sure that the oor grinder can be stopped quickly.

DANGER

Death or severe injury can result if the safety information in the “Floor grinding safety

manual” is not observed.

▶Make sure that the “Floor grinding safety manual” is read completely and has been

understood.

2.4

2.4.1

2.4.2

2.4.3

2.4.4

2.4.5

2.4.6

2.4.7