Printed in USA

©2001

Page 2

E-EDG7-PL-1201

100 Thomas Johnson Drive, Frederick, MD 21702-4600 USA

Phone (301) 663-1600 • 1-800-638-3326

Fax (301) 663-1607 • 1-800-447-3326

READ AND UNDERSTAND THE OPERATORS INSTRUCTION MANUAL THOROUGHLY BEFORE ATTEMPTING

TO OPERATE THIS EQUIPMENT. Death or serious injury could occur if this machine is used improperly.

SAFETY

MESSAGES

The safety instructions are proceeded by a graphic alert message of

DANGER, WARNING, or CAUTION.

Indicates an imminent hazard which, if not avoided,

will result in death or serious injury.

Indicates an imminent hazard which, if not avoided,

will result in death or serious injury.

Indicates hazards which, if not avoided, could result

in serious injury and or damage to the equipment.

GASOLINE

Powered Equipment

• Do not operate gasoline powered equipment without adequate ven-

tilation. Carbon monoxide is an invisible, odorless gas that can kill.

ELECTRICAL

Powered Equipment

•ELECTRICAL HAZARD - Be sure equipment is properly grounded.

Failure to comply could kill or result in serious injury.

The engine exhaust from this product contains chemicals known to

the State of California to cause cancer, birth defects or other reproduc-

tive harm.

!!

!!

!

GENERAL INSTRUCTIONS

• You must read and understand the operators instruction manual and

all other manuals associated with this machine. For your safety

and the safety of others around you, it is extremely important to fully

understand how to operate this machine in the way it was intended.

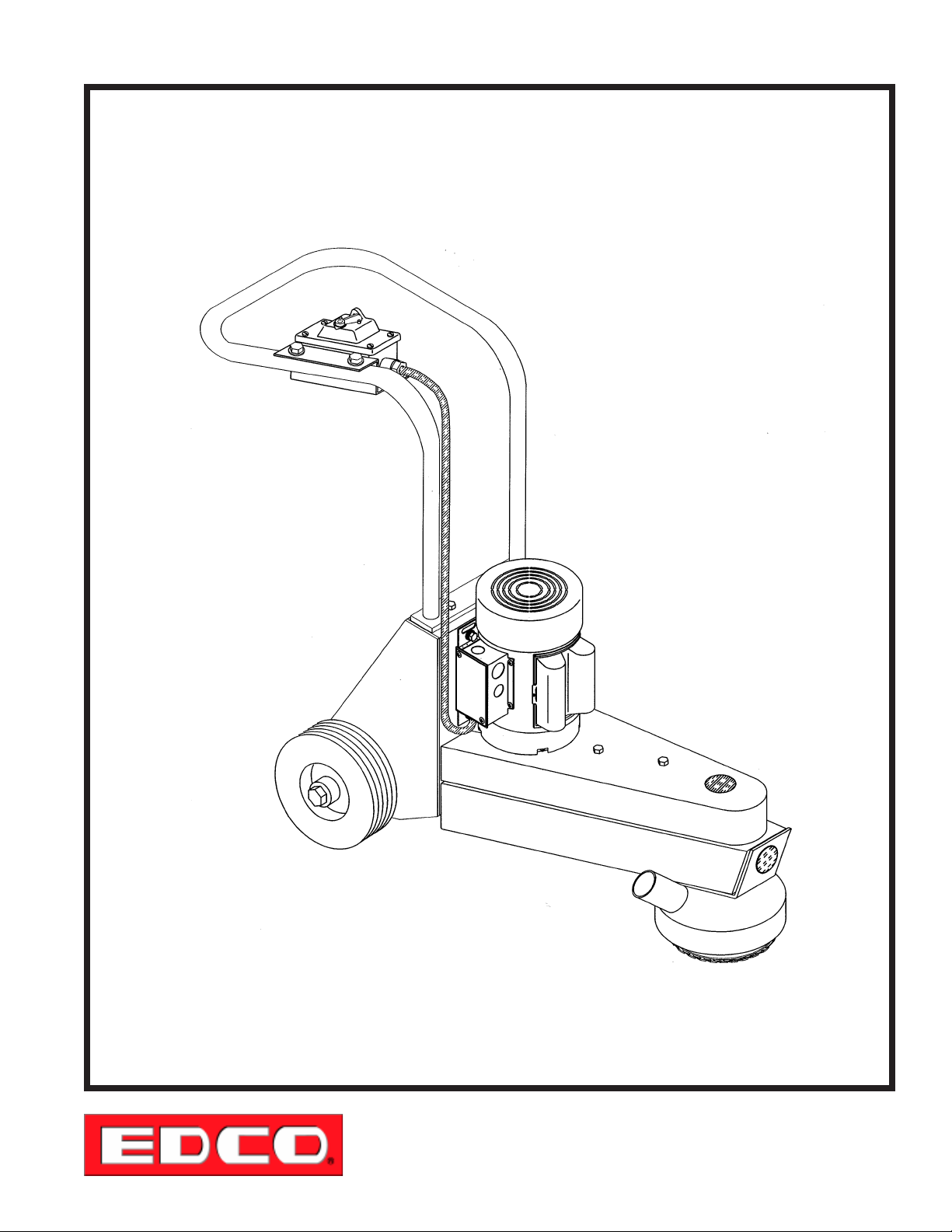

Different model machines or older/newer versions of the same model

may have different parts and controls that you need to understand.

If instructions are not readable or available DO NOT USE this

machine and contact the factory for a replacement Manual.

• You must be able to physically handle the bulk weight and power of

this machine. If not properly controlled this machine can cause

death or serious injury.

• Do not operate this machine in an impaired mental state. You must

be able to exercise good judgement and reactions to maintain a safe

working environment.

• This is a “one person” machine which means only one operator can

be operating the machine at any one time. For the safety of others,

maintain a safe operating distance to other personnel. Your work

area should be defined and appropriately marked so bystanders

and coworkers do not stand or walk near this machine and end up

seriously injured by flying debris or exposing them to harmful noise

or dust.

• This equipment is for Commercial use. Although this is a “one

person” machine your work team should understand how to shut

this machine off and quickly get medical help if an accident strikes

the operator.

• Keep all guards in place during operation. The guards are to pro-

vide protection from inadvertent contact with dangerous moving

parts, pinch points, or hot surfaces.

• Wear appropriate Personal Protective Equipment (PPE) including

safety glasses, safety boots, work gloves, respiratory protection,

!!

!!

!

hearing protection, and head protection. Do not wear loose clothing

that can get tangled in moving parts. Failure to do so could result in

dismemberment or death. Wear an approved respirator when re-

moving hazardous materials or when grinding/cutting dry materials.

Some dust particles such as concrete dust can contain silicate

particles which can cause silicosis (a very serious lung disease).

Contact NIOSH or OSHA for further details. When wet grinding/

cutting, avoid contact with the concrete/asphalt slurry which can

cause serious skin irritations.

• You must maintain this machine per the maintenance schedule in

the operator manual. Remember before adjusting, servicing, or

fueling this machine, disconnect the source of power to the machine

by disconnecting the spark plug (Gas models), or by unplugging the

electrical power cord (electric models) or air hose (Pneumatic

models) AT THE MACHINE so you can assure yourself it remains

unplugged while you are working on it. Do not modify this machine.

Use only genuine EDCO parts and accessories. Repairs and ser-

vice should be performed by approved EDCO dealers or authorized

technicians.

• You should look carefully around the area before you begin work so

you can identify potential hazards such as deck inserts, pipes,

columns, openings, electrical cords or outlets, or any other objects

protruding from the slab surface.

• This machine has no brain so you must use your own. There is no

substitute for safety. The safety decals on the machine are to serve

as a reminder for information you must already know before you

begin using this machine. Take a moment to reread the safety

decals each time you use the machine. If your machine is missing

any decals, contact the factory for a replacement (EDCO 1-800-

638-3326).