4 Maintenance

EN Floor grinding machine FGE 400

9

4 Maintenance

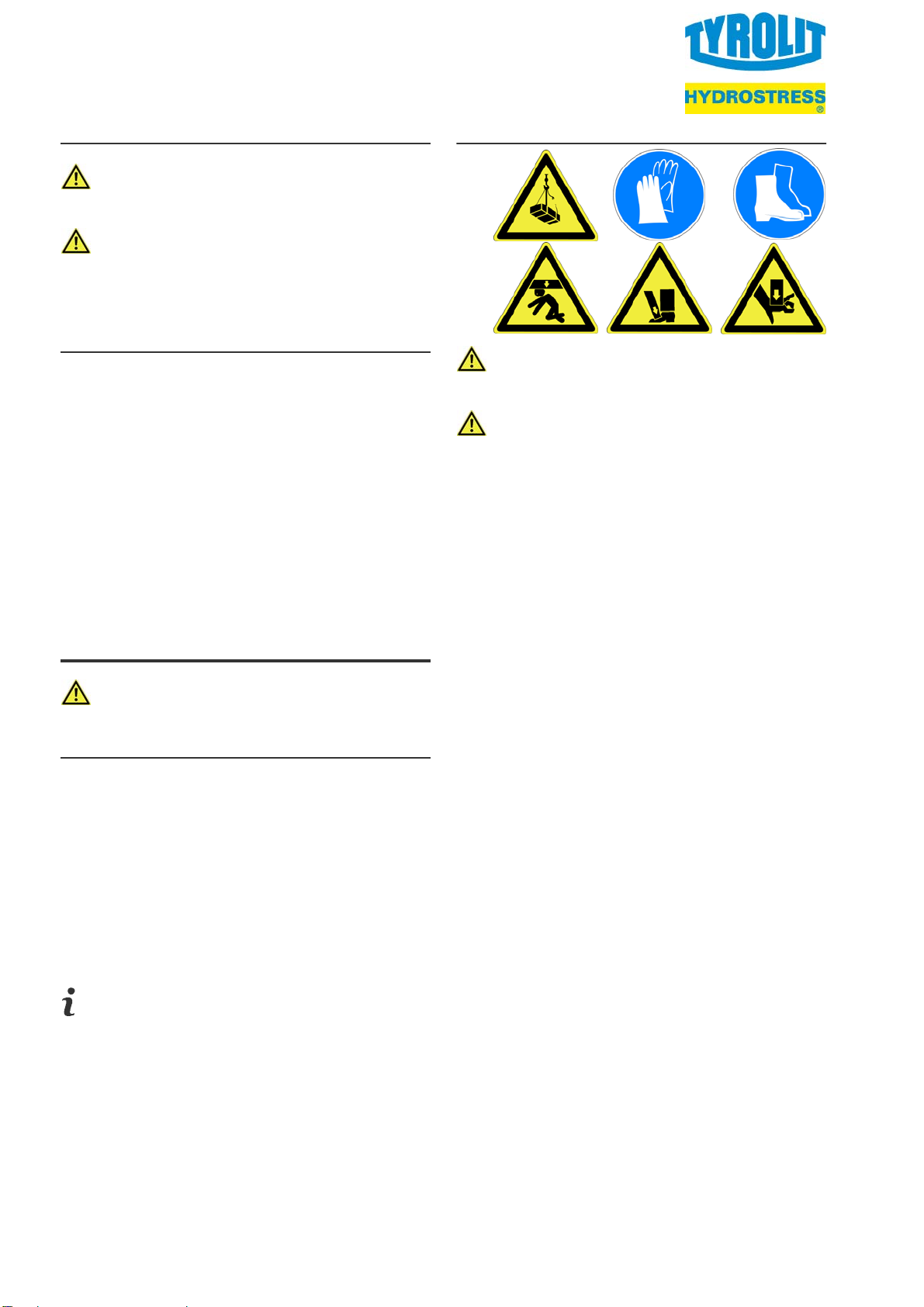

Follow the safety instructions in Chapter 2!

The operating and maintenance personnel resp

onsible for the machine must ensure that no one

can enter the machine's danger zone during

operation or maintenance work.

Maintenance work may only be performed by

trained specialists! They must be familiar with

the dangers associated with such work, protect

themselves and avoid danger!

When working on the machine (set-up, mainte

nance, service, repair, cleaning, etc.), the power

supply of the machine has to be disconnected

from the mains

(disconnect the plug) and the drive must be at a

standstill!

Perform cleaning and maintenance work in ac

cordance with the operating manual and check

the safety devices for completeness and functio

nality.

4.1 Customer service and spare parts

In case of customer service queries, replacement

parts or repairs, please contact the manufacturer. To

ensure your queries are dealt with as quickly as pos

sible, always quote your machine data. These are

located on the machine's nameplate.

4.2 Attaching/Removing additional weights

Risk of injury from heavy additional weights!

Only grip the additional weights at the recessed

handles [25, Fig. L]! Work with care!

1. Screw 2 bolts [23, Fig. K, spanner size 13] into

the safety hood [7, Fig. J].

2. As needed, grip 1 ... 3 additional weights

[24, Fig. L] and slide these over the bolts.

The removal is carried out in logical reverse

order.

4.3 Tilting the machine

Before tilting the machine, always make sure

that it is on an even, level floor surface!

1. Disconnect the power plug [2, Fig. A] from the

mains.

2. Swivel and lock the guide handle [1, Fig. A] in

the stretched position (!Chapter 3.1).

3. Remove additional weights (!Chapter 4.2).

4. Tip the machine and place it on the floor

(!Fig. C/N/R).

4.4 Mounting and dismantling ETX diamond tools

The consistency of the surface to be ground de

termines the type or composition of the tools to be

used.

All of the ETX diamond tools [!Fig. D] authori

zed for this machine are removed and mounted

in the same manner.

Always mount tools of the same type according

to the processing specifications. The heights of

the diamond tools (degree of wear) must be the

same.

1. Tilt the machine (!Chapter 4.3).

2. Gently tap with a lump hammer to loosen the

tools [13, Fig. E] from the EXT locating

plate [14, Fig. C/E] in the direction of the centre

and then remove.

3. Insert new tools in the ETX holder [17, Fig. E]

and press toward the outer edge of the ETX lo

cating plate (use lump hammer if necessary).

4. Set the machine upright, swivel and lock the

guide handle in standard position

(!Chapter 3.1).

4.5 Cleaning the machine

Do not use high pressure cleaners or com

pressed air to clean the machine!

1. Tilt the machine (!Chapter 4.3).

2. After use, clean the machine and tools with a

dry method such as a vacuum cleaner with a

suitable filter, a cloth or a brush.

3. Set the machine upright, swivel and lock the

guide handle in standard position

(!Chapter 3.1).