Table of contents

Page

1. Safety ........................................................................... 5

1.1 Generally applicable safety instructions ..................................... 5

1.2 Signs on the equipment .................................................... 6

1.3 Action in an emergency .................................................... 6

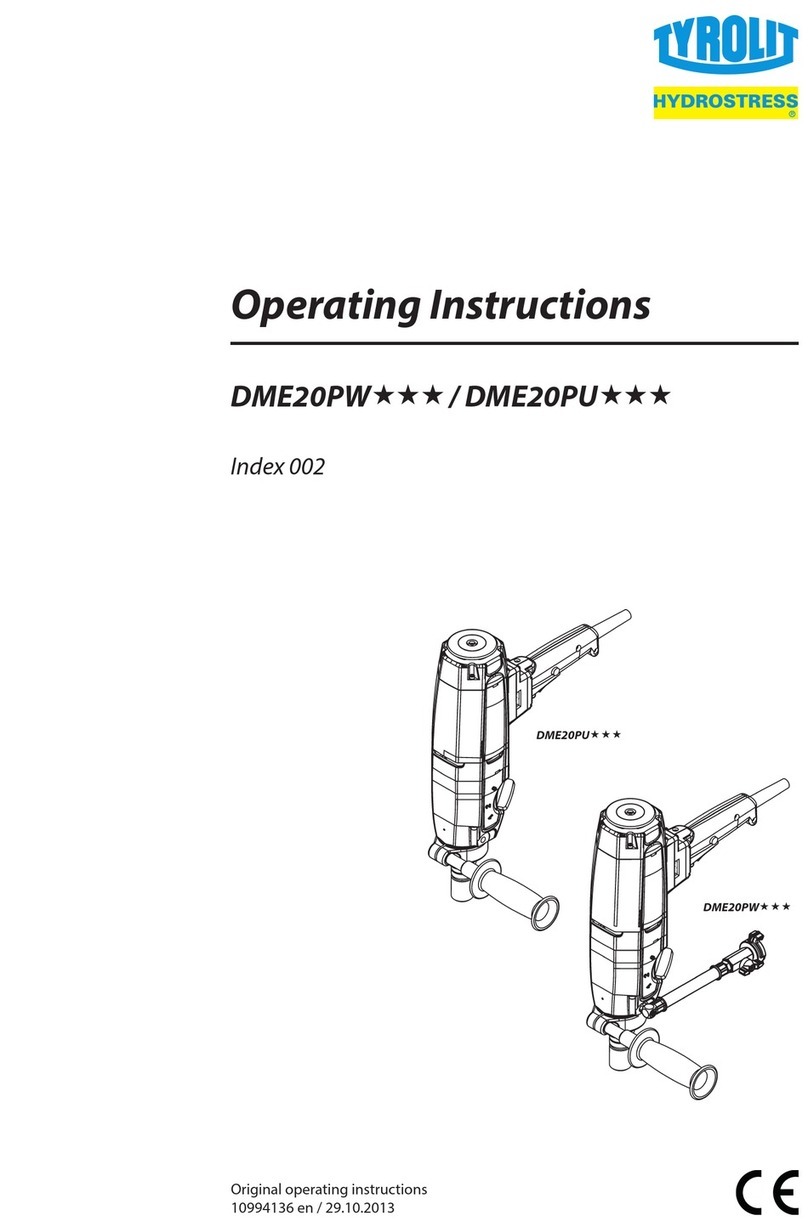

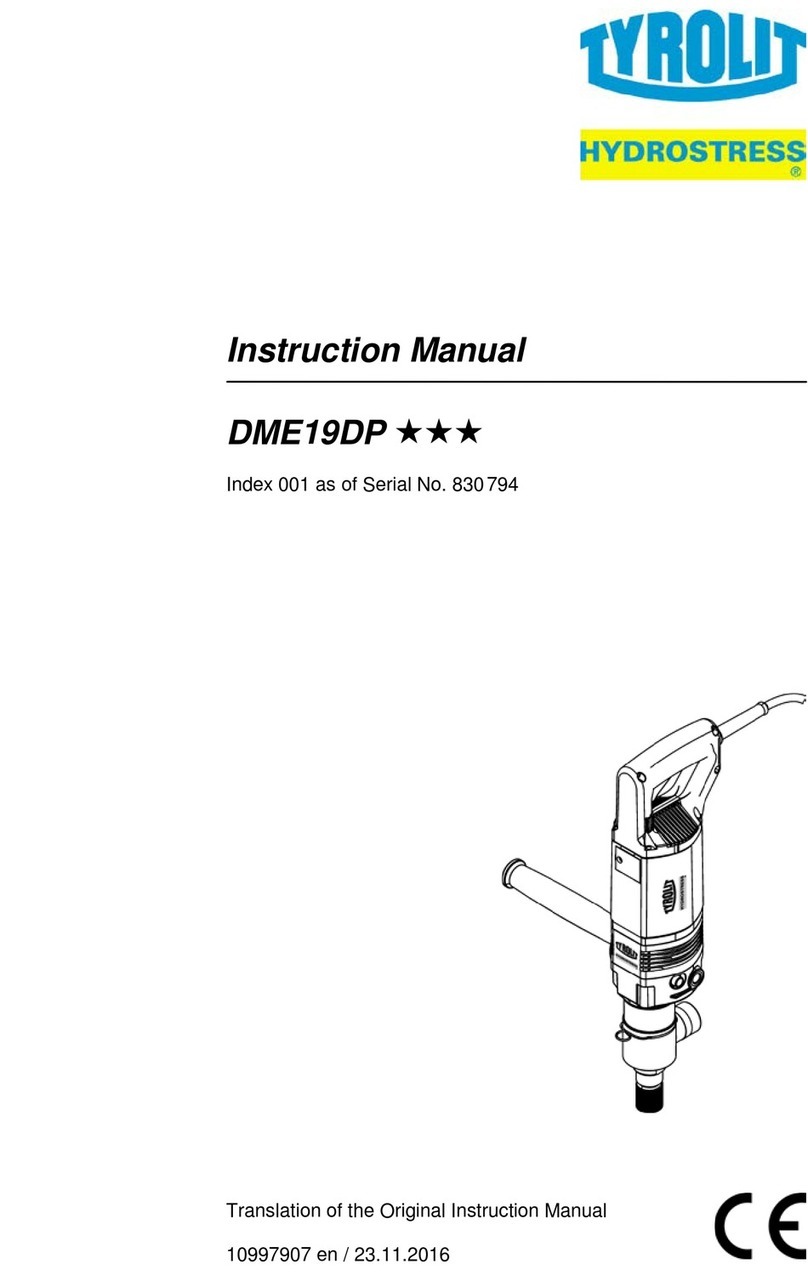

2. Description ..................................................................... 7

2.1 Wall saw system ............................................................ 7

2.2 Intended use ............................................................... 7

2.3 Wall saw system components ............................................... 7

2.4 Main components of the wall saw head ..................................... 8

3. Mounting / removal ............................................................. 9

3.1 Placing the wall saw on the guide rail ....................................... 9

3.2 Adjusting the guide rollers.................................................. 10

3.3 Mounting the motor........................................................ 11

3.4 Securing the motor......................................................... 12

3.5 Removing the motor ....................................................... 13

3.6 Mounting the saw blade .................................................... 14

3.7 Mounting the saw blade unit ............................................... 17

3.8 Removing the saw blade unit ............................................... 18

3.9 Blade guard ................................................................ 19

3.10 Connecting the control unit ................................................ 20

4. Operation ....................................................................... 24

4.1 Overview of controls ....................................................... 24

4.2 Starting the wall saw ....................................................... 26

4.3 Changing the frequency of the remote controller............................ 27

4.4 Selecting the mains power supply .......................................... 28

4.5 Selecting the tool station ................................................... 29

4.6 Adjusting the feed.......................................................... 30

4.7 Manually adjusting the feed speed.......................................... 31

4.8 Locking the feed ........................................................... 31

4.9 Changing the direction of rotation of the main motor. . . . . . . . . . . . . . . . . . . . . . . . 32

4.10 Switching o the wall saw .................................................. 33

4.11 Deactivating the EMERGENCY STOP function ................................ 34

4.12 After nishing work. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.13 Responding to displays ..................................................... 36

4.14 Power displays ............................................................. 37