Contents...................................................................................................................................3

Important Information

.............................................................................................................4

...............................................................................................................................4

Explanation of the pictograms on the dry drilling motor..........................................................4

Explanation of the pictograms used in the text.......................................................................4

........................................................................................................................5

General Safety Instructions for Power Tools ..........................................................................5

1) Safety at the place of work..............................................................................................5

2) Electrical safety...............................................................................................................5

3) Safety of persons............................................................................................................6

4) Using and handling the power tool ..................................................................................6

5) Service............................................................................................................................7

Machine-Specific Safety Instructions......................................................................................7

Operating personnel requirements.....................................................................................7

Workplace safety ...............................................................................................................7

Electrical safety..................................................................................................................8

Safety of people.................................................................................................................9

Hazards when using and handling the power tool ............................................................10

Service / Maintenance / Repair ........................................................................................11

Technical Characteristics

.....................................................................................................12

Technical specifications.......................................................................................................12

Machine characteristics .......................................................................................................12

Declaration of Conformity

.....................................................................................................13

....................................................................................................................13

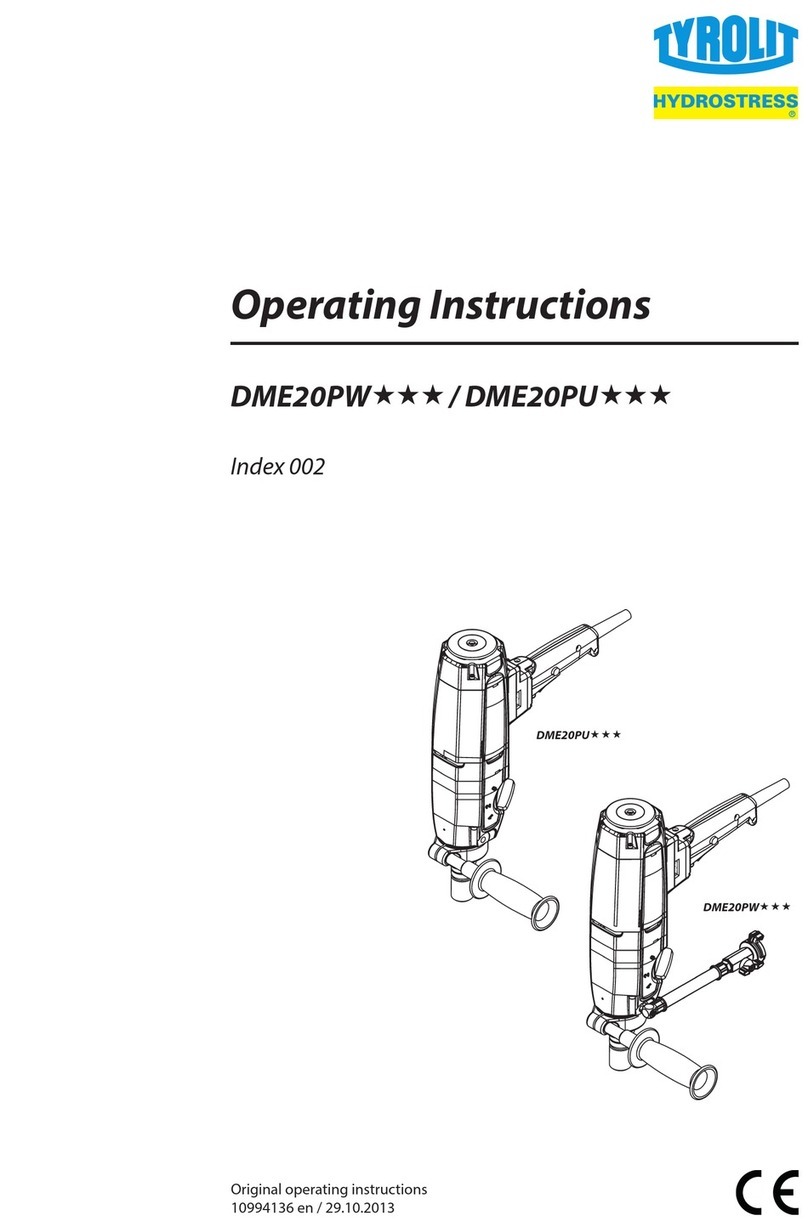

Machine parts and controls

..................................................................................................14

..........................................................................................................15

..........................................................................................................................15

.............................................................................................................16

Fit / dismantle extraction tube..............................................................................................16

Switch soft impact feature on and off ...................................................................................17

...........................................................................................................18

Fit or replace diamond dry core bit.......................................................................................18

Hand-held drilling.................................................................................................................19

Using the centring tip .......................................................................................................19

Connect dust extractor to the extraction tube ...................................................................20

Switching on the dry drilling motor and drilling..................................................................20

Drill centring hole..........................................................................................................20

Finishing the drilled hole...............................................................................................21

Ending the drilling process ...........................................................................................22

Remove drill core .........................................................................................................22

-guided core drilling ....................................................................................................23

Handling diamond dry core bits

...........................................................................................24

.................................................................................................................................24

Maintenance...........................................................................................................................24