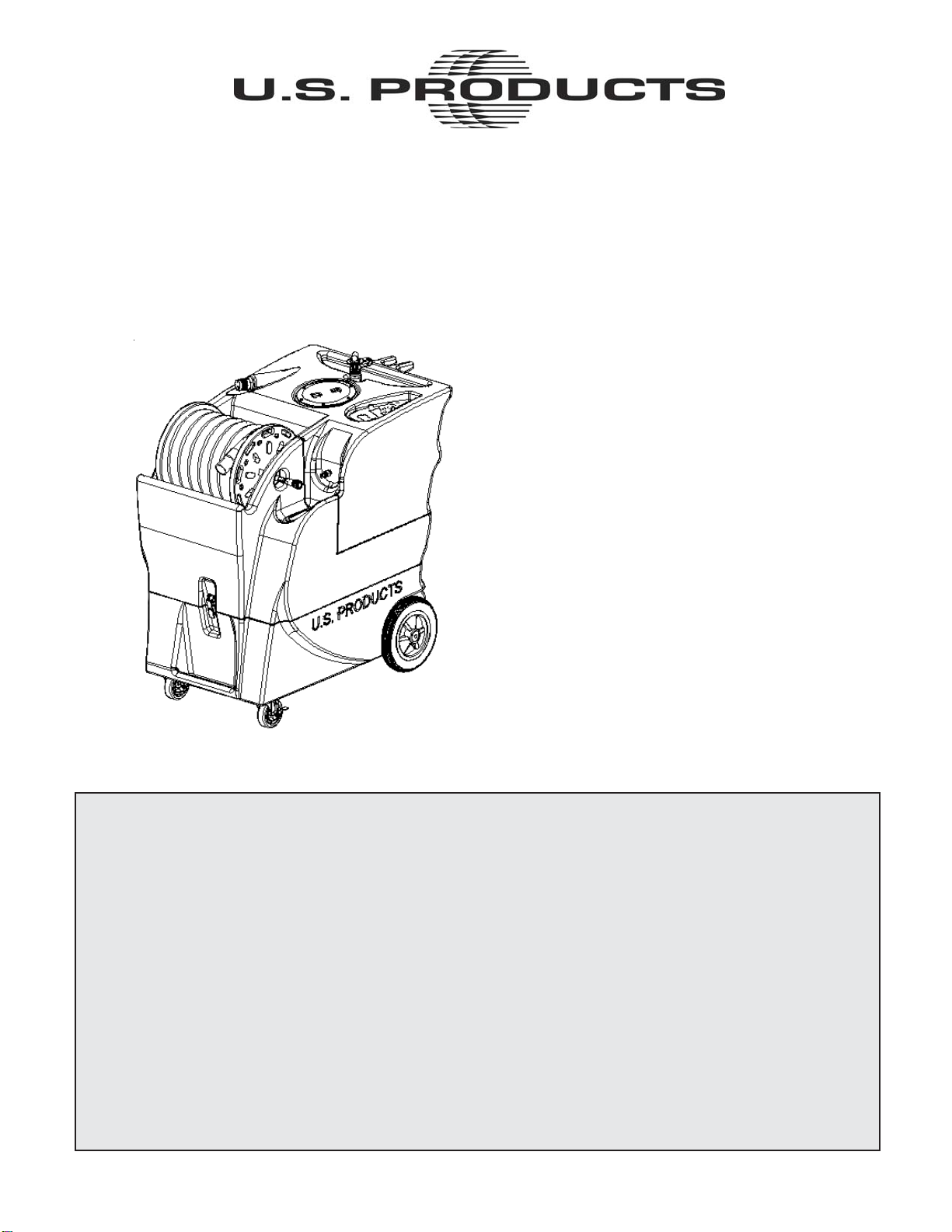

KING COBRA-500-JP

100V

PART LIST

1 805 Chain, lid, 8”

2 901B Lid, solution tank

3 Holding Tank, white

4 1088 Glide, teflon

5 178 Screw, 6-32 X 1/2”

6 925 Hose, 3/8” I.D. X 24”

7 164 Hose barb, brass, 3/8” hose

8 91 Elbow, 90 degree

9 945D Valve, pump unloader

10 92A Nipple, S/S

11 216 Elbow, brass

12 168 “T”, brass, 1/4 p.t.

14 211 Plug, brass, 1/4 p.t.

15 950C Pump, no motor

16 97 Reducer, brass

17 223 Quick connect, male, 1/8 p.t.

18 165 Hose barb, brass, 1/2” hose

19 1147 Cap screw, pump to motor

20 950D Cam/bearing assembly

21 946 Hose, 1/2” I.D. X 18”

22 FP348B Hose, pump to heater, 12”

23 FP411 Hose assembly, pump to gauge

24 913B Vacuum motor, 3-stage

25 959 Gasket, vacuum motor

27 926 Manifold, vacuum motor mount

28 1136 Hose, vacuum inlet, 1-1/2” X 24“

29 907 Hose barb, for vacuum hose

31 1148 Screw, 8-32 X 1”

32 2086 Lid, vacuum, with ring

33 1074 Gasket, lid

34 1060C Plug, drain hose

35 1060B Hose, drain, 1-1/2” X 24”

36 156 Hose clamp

37 207A Filter, pump inlet

38 2026 Float switch

39 CWKC-BLK Cord wrap, Black

41 1146 Pipe, 6.85”, S/S

42 45 Quick connect, male, 1/4 p.t.

43 1144 Rubber sleeve, 1/2” ID X 5”

44 1062 Receptacle, power cord

45 1057B Power cord, 25 ft, 3/12, yellow

46 Vacuum tank, white

46A 1131 Elbow, PVC

47 948B Motor, pump, DC out,

48 FP361 PCB, pump motor speed,

49 FP225 PCB, vacuum control

50 2B1 Screw, 6-32 X 2-1/4”

51 2014 Fan, cooling

51A 2015 Guard, fan

52 908A Latch, draw, rubber

53 928 Louver, 3”, includes 3 screws

54 BKCR-BLK Base, black

55 905 Castor, 4”

56 176A Hose clamp

57 929 Filter, vacuum inlet

57A 1139 Elbow, 45°

58 FP348 Heat exchanger

59 455 Bracket, mounting, heater

60 ---- See miscellaneous Parts and Kits

61 918 Plate, heat sink

62 FP348A Hose, heater to outlet

65 910 Axle, 21”

66 2084 Wheel, 10”

67 27A Axle cap

68 943001 Switch plate

69 951B Pressure gauge

70 28 Screw, #4 X 3/8”

71 FP399 Potentiometer, with cable, pump

71A 248 Knob, blue top, for pump speed

72 78B Light, red,

73 FP345 Switch & actuator, vacuum

75A 248 Knob, red top, for heat adjustment

75 FP347 Potentiometer, with wires, heat

77 FP351 Gasket, (#1043A X 84”)

78 1128 Label, KC-500

81 FP350C Vac and pressure line complete, 25 ft

82 FP350A Reel complete, without hoses

7-31-07

MISCELLANEOUS PARTS AND KITS

FP194E Heat repair kit includes probe, thermistor control,

thermal cutout & instructions

(for machines built after June, 2005)

FP409 Pump & motor complete, w/unloader 500 psi

FP410 Pump complete w/unloader, no motor

950CP Pump rebuild kit, valves and O-rings, 500 psi

250 Pump rebuild kit, piston and seals, 500 PSI

SYP1 Syphon hose

FP350B Pressure line, complete with swivel end. 25 ft.

FP350 Vacuum hose & pressure line with reel, complete

FP469 Swivel hose assembly, 16-1/2”, without reel

ITEM PARTNo DESCRIPTION ITEM PARTNo. DESCRIPTION

(NOTE: Items in kits not sold separately.)