3

Table of Contents

Safety Notes .................................................................................................................. 4

Getting Started .............................................................................................................. 5

1.1 Product Overview...................................................................................................5

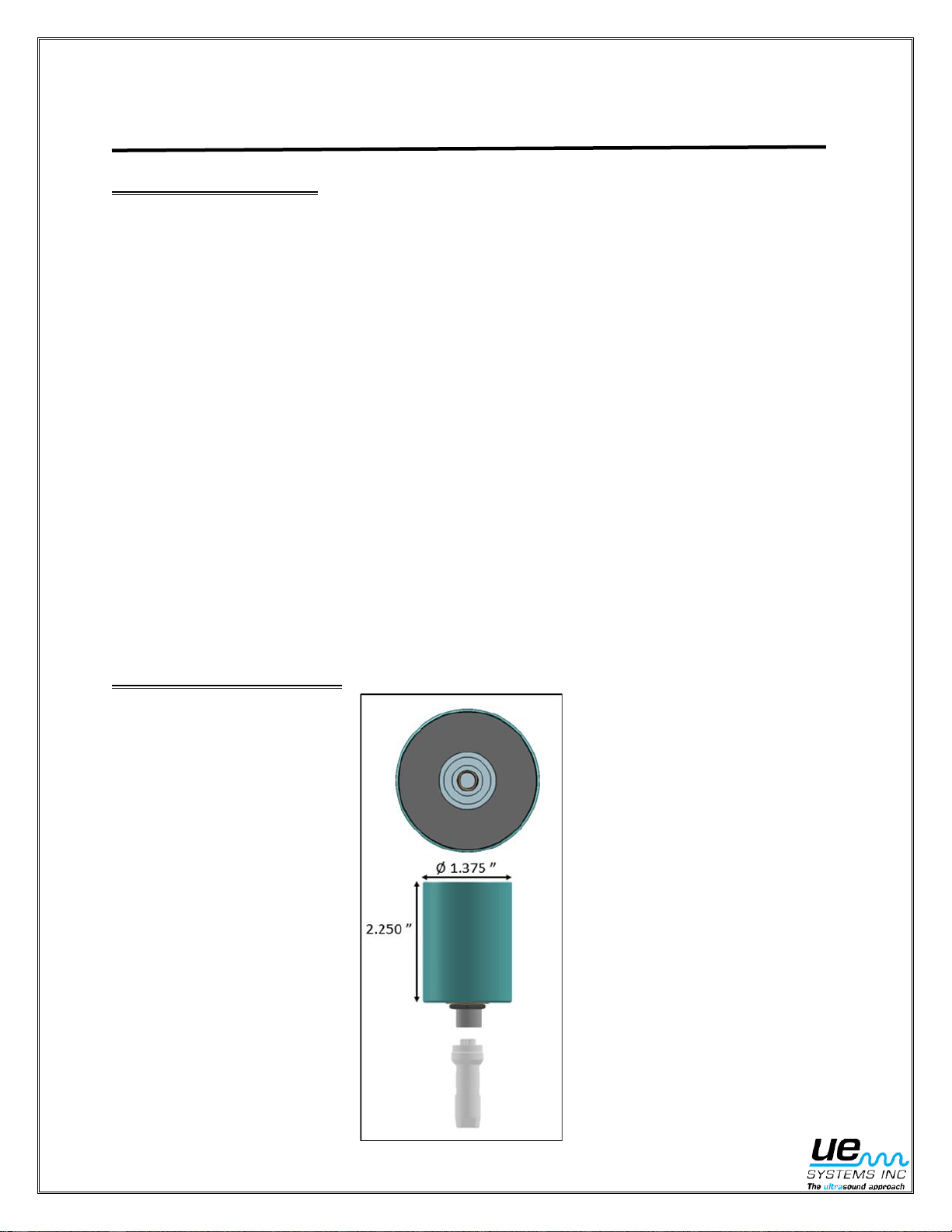

1.2 Product Dimensions...............................................................................................5

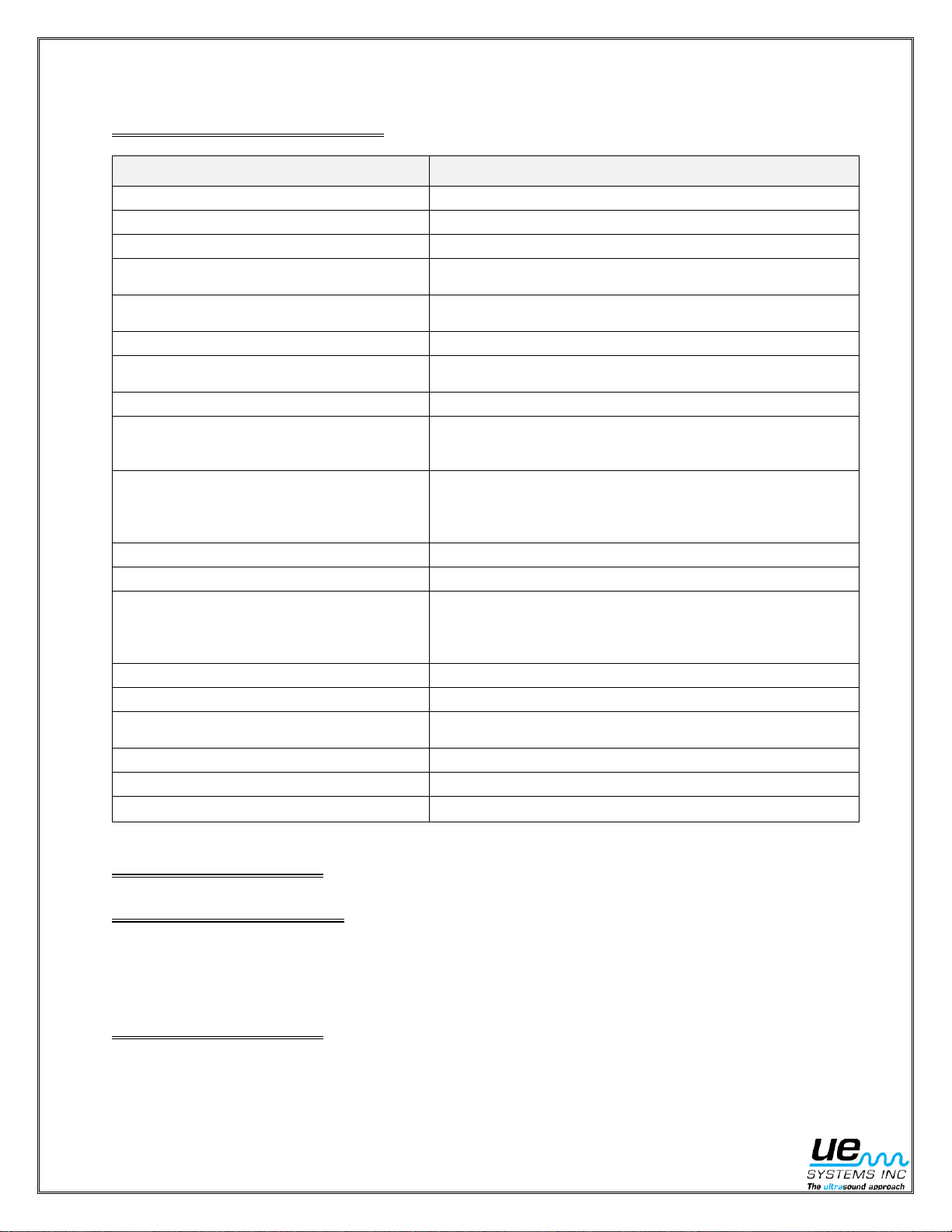

1.3 Product Specifications............................................................................................6

1.4 Product Operation..................................................................................................6

1.4.1 Power Requirements...................................................................................6

1.4.2 Sensitivity Control........................................................................................6

1.4.3 Wiring Connections .....................................................................................7

1.4.4 Current Output and Power Supply Current Draw......................................... 7

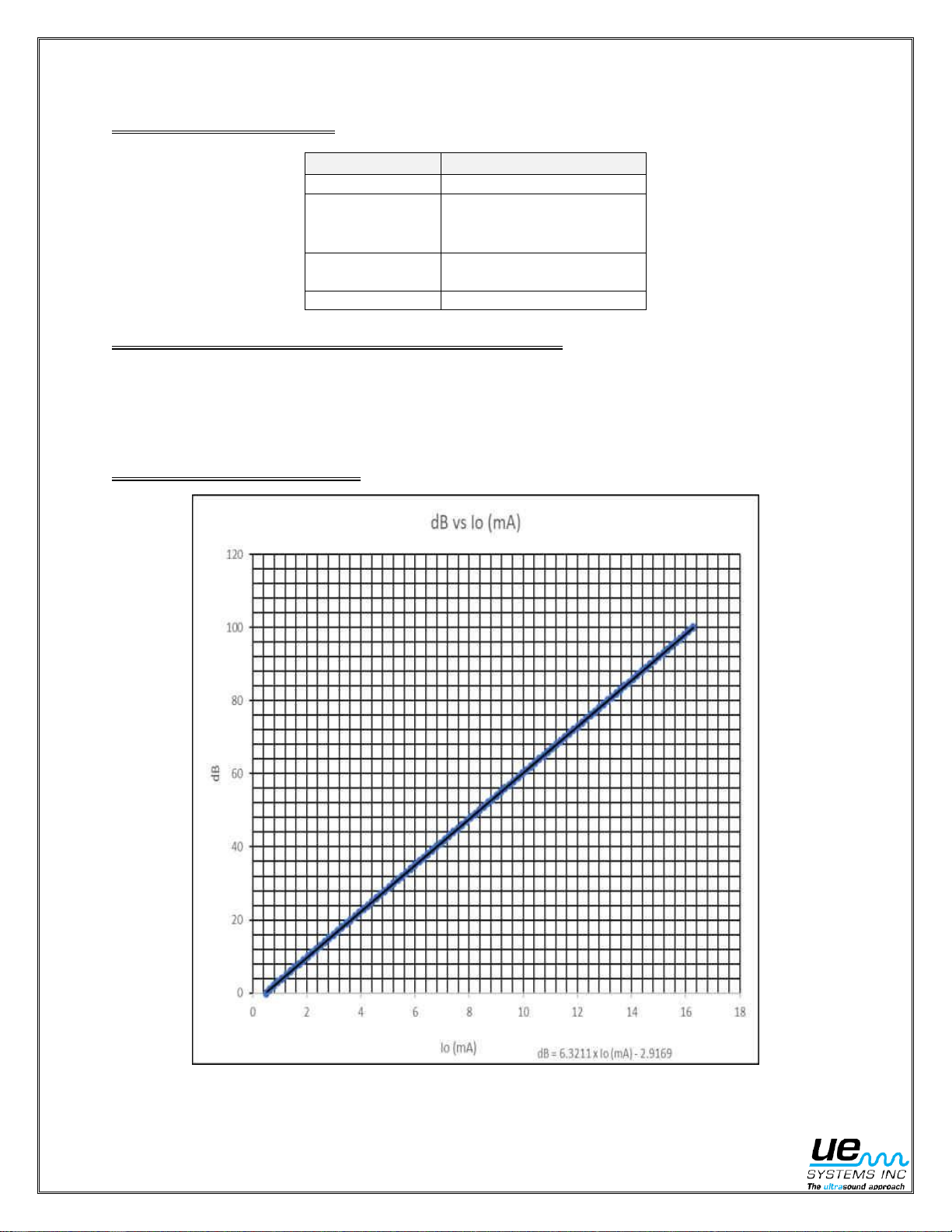

1.4.5 Typical Transfer Curve ................................................................................7

1.5 Common Applications............................................................................................8

1.5.1 Bearing Condition Monitoring and Lubrication.............................................8

1.5.2 Valve and Steam Trap Monitoring...............................................................9

1.6 Ultrasound Technology........................................................................................ 10

Sensor Placement and Installation............................................................................ 11

2.1 Primary Considerations........................................................................................ 11

2.2 Additional Considerations .................................................................................... 12

2.3 Proper Mounting................................................................................................... 12

2.4 Mounting Options................................................................................................. 13

2.4.1 Adhesive Stud Mount ................................................................................ 13

2.4.2 Fin Mount................................................................................................... 13

2.5 Accessories.......................................................................................................... 14

Customer Support....................................................................................................... 15