WARRANTY

(a.) Limited Product Warranty Statements. For each Product purchased from Seller or an authorized reseller, Seller makes the following limited

warranties: (i) the Product is free from defects in material and workmanship, (ii) the Product materially conforms to Seller’s specifications that are

attached to, or expressly incorporated by reference into, these terms, and (iii) at the time of delivery, Seller has title to the Product free and clear of

liens and encumbrances (collectively, the “Limited Warranties”). Warranties with respect to software which may be furnished by Seller as part of the

Product, if any, are expressly set forth elsewhere in these terms. The Limited Warranties set forth herein do not apply to any software furnished by

Seller.

(b.) Conditions to the Limited Warranties. The Limited Warranties are conditioned on (i) the Product being stored, installed, operated and

maintained in accordance with Seller’s instructions, (ii) no repairs, modifications or alterations being made to the Product other than by Seller or its

authorized representatives, (iii) the Product being used in compliance with any conditions or parameters set forth in specifications that are attached

to, or expressly incorporated by reference into, these terms, (iv) use of the Product being discontinued after the Buyer or user has, or should have had,

knowledge of any defect in the Product, (v) Buyer providing prompt written notice of any warranty claims within the warranty period described

below, (vi) at Seller’s discretion, Buyer either removing and shipping the Product or non-conforming part thereof to Seller, at Buyer’s expense, or

Buyer granting Seller access to the Products at all reasonable times and locations to assess the warranty claims, and (vii) Buyer not being in default of

any payment obligation to Seller.

(c.) Exclusions from Limited Warranty Coverage. The Limited Warranties specifically exclude any equipment comprising part of the Product that

is not manufactured by Seller or not bearing its nameplate. To the extent permitted, Seller hereby assigns any warranties made to Seller for such

equipment. Seller shall have no liability to Buyer under any legal theory for such equipment or any related assignment of warranties. Additionally,

any Product that is described as being experimental, developmental, prototype, or pilot is specifically excluded from the Limited Warranties and is

provided to Buyer “as is” with no warranties of any kind. Also excluded from the Limited Warranties are normal wear and tear items,including any

expendable items that comprise part of the Product, such as fuses, light bulbs and lamps.

(d.) Limited Warranty Period. Buyer shall have 12 months from initial operation of the Product or 18 months from shipment, whichever occurs

first, to provide Seller with prompt, written notice of any claims of breach of the Limited Warranties. Continued use or possession of the Product

after expiration of the warranty period shall be conclusive evidence that the Limited Warranties have been fulfilled to the full satisfaction of Buyer

and user, unless Buyer has previously provided Seller with notice of a breach of the Limited Warranties.

(e.) Remedies for Breach of Limited Warranty. Buyer’s sole and exclusive remedies for any breach of the Limited Warranties are limited to

Seller’s choice of repair or replacement of the Product, or non-conforming parts thereof, or refund of all or part of the purchase price for the subject

Product or part. The warranty on repaired or replaced Product or parts is limited to the remainder of the original warranty period. Buyer shall be

responsible for any labor required to gain access to the Product so that Seller can assess the available remedies,and Buyer shall be responsible for all

costs of installation of repaired or replaced Products or parts. All Products or parts replaced under this Limited Warranty will become the property of

Seller.

(f.) Transferability. The Limited Warranties shall be transferable during the warranty period to the initial end-user of the Product.

THE LIMITED WARRANTIES SET FORTH IN THIS SECTION ARE SELLER’S SOLE AND EXCLUSIVE WARRANTIES AND ARE

SUBJECT TO THE LIMITS OF LIABILITY SET FORTH BELOW. SELLER MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING, WITHOUT LIMITATION, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, OR ANY

WARRANTIES THAT MIGHT ARISE FROM COURSE OF DEALING OR USAGE OF TRADE.

LIMITATION OF LIABILITY. NEITHER SELLER, NOR ITS SUPPLIERS, SHALL BE LIABLE, WHETHER IN CONTRACT,

WARRANTY, FAILURE OF A REMEDY TO ACHIEVE ITS INTENDED OR ESSENTIAL PURPOSES, TORT (INCLUDING NEGLIGENCE),

STRICT LIABILITY, INDEMNITY OR ANY OTHER LEGAL THEORY, FOR LOSS OF USE, REVENUE, SAVINGS OR PROFIT, OR FOR

COSTS OF CAPITAL OR OF SUBSTITUTE USE OR PERFORMANCE, OR FOR INDIRECT, SPECIAL, LIQUIDATED, PUNITIVE,

EXEMPLARY, COLLATERAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES, OR FOR ANY OTHER LOSS OR COST OF A SIMILAR

TYPE, OR FOR CLAIMS BY BUYER FOR DAMAGES OF BUYER’S CUSTOMERS. SELLER’S MAXIMUM LIABILITY UNDER ANY

LEGAL THEORY SHALL BE THE ACTUAL PURCHASE PRICE RECEIVED BY SELLER FOR THE PRODUCT AT ISSUE OR ONE

MILLION DOLLARS, WHICHEVER IS LESS. BUYER AGREES THAT THE EXCLUSIONS AND LIMITATIONS SET FORTH IN THIS

ARTICLE ARE SEPARATE AND INDEPENDENT FROM ANY REMEDIES WHICH BUYER MAY HAVE HEREUNDER AND SHALL BE

GIVEN FULL FORCE AND EFFECT WHETHER OR NOT ANY OR ALL SUCH REMEDIES SHALL BE DEEMED TO HAVE FAILED OF

THEIR ESSENTIAL PURPOSE.THESE LIMITATIONS OF LIABILITY ARE EFFECTIVE EVEN IF BUYER HAS ADVISED SELLER OF

THE POSSIBILITY OF SUCH DAMAGES.

2

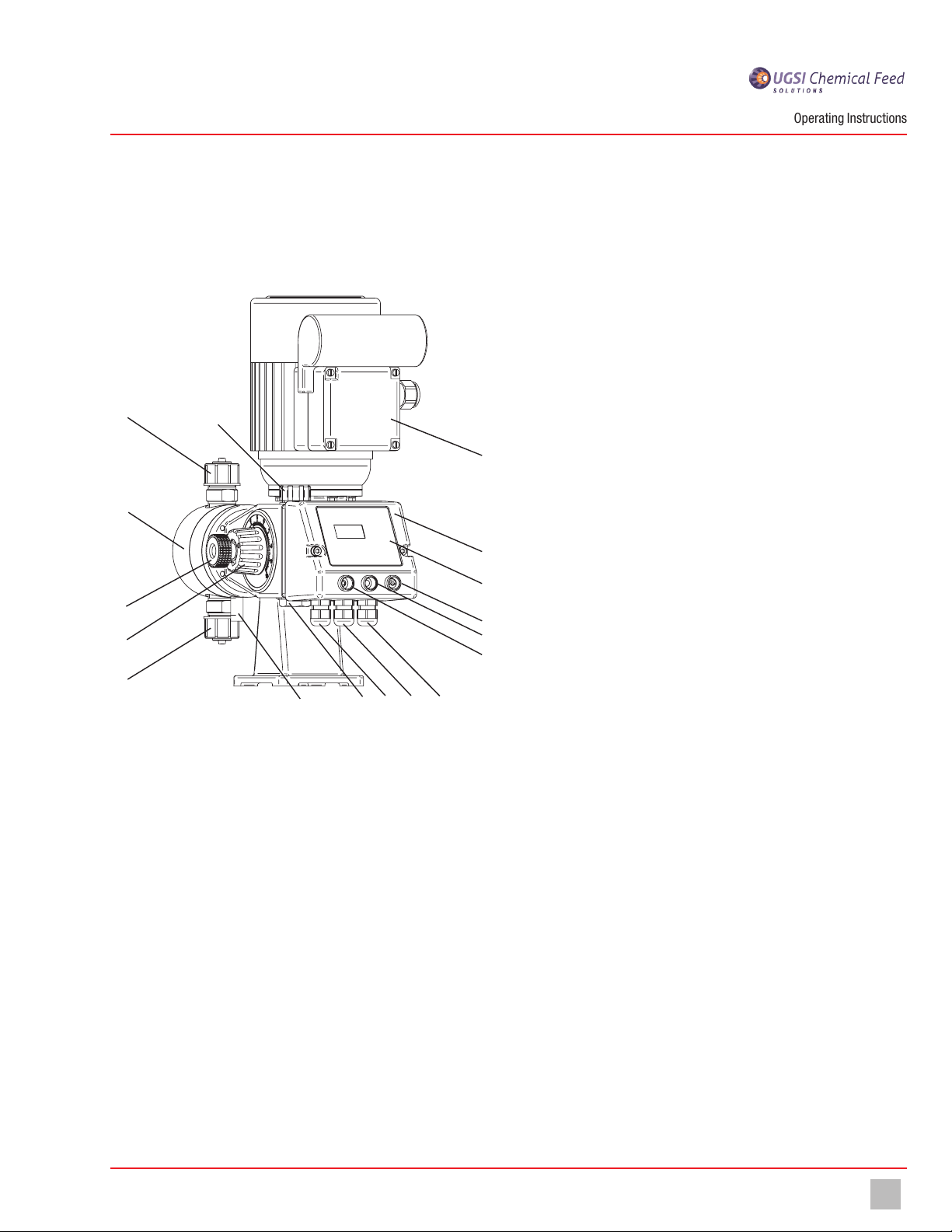

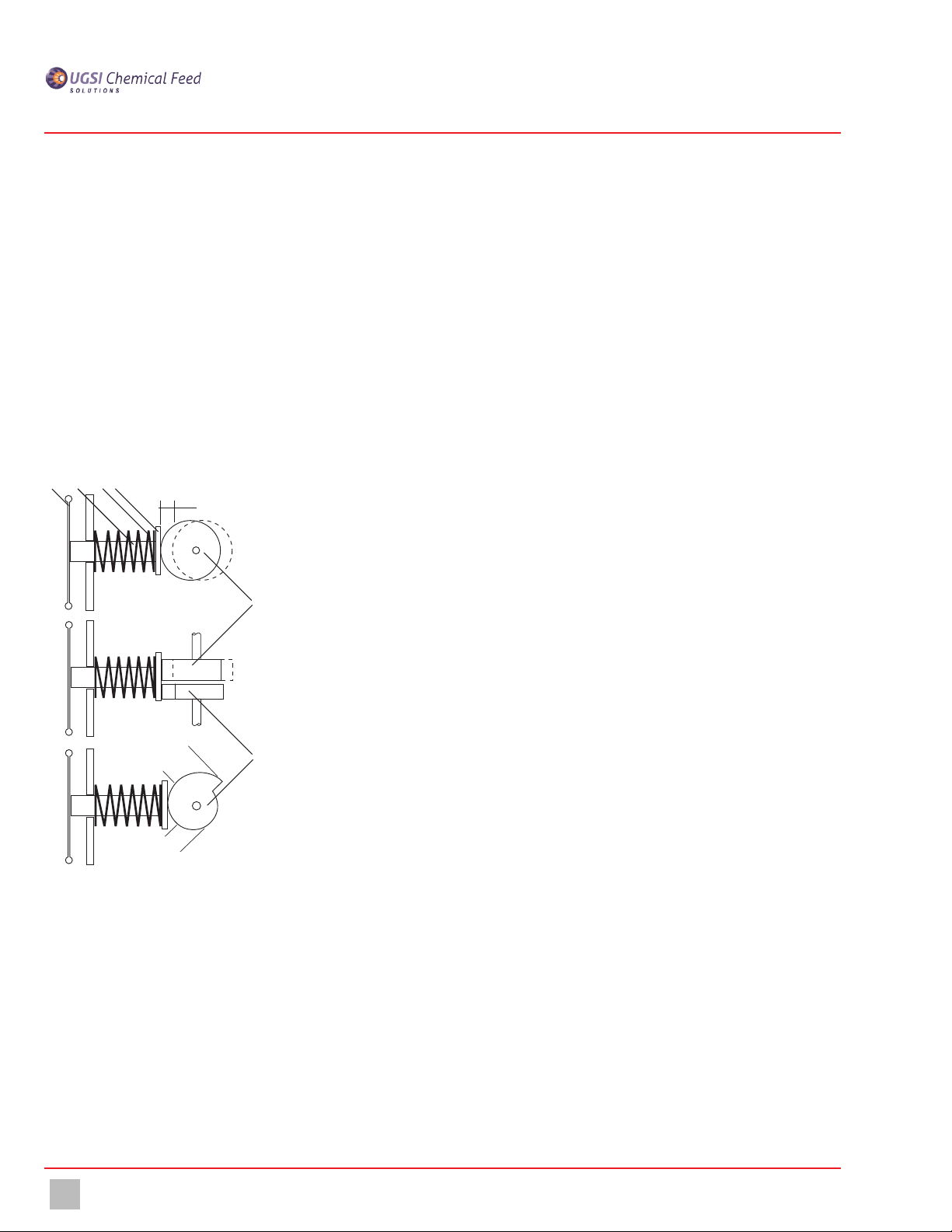

Diaphragm Dosing Pump Encore®MB/ME Operating Instructions

CF.450.410.001.IM.1114