Umwelt-Geräte-Technik GmbH | Eberswalder Str. 58 | D-15374 Müncheberg | phone: +49 (0) 33 43 2 - 89 575 | www.ugt-online.de Page 7 of 12

The water flow equilibrating the pressures goes on until the negative pressure in the

measurement volume corresponds to the negative pressure in the surrounding soil. If the

surrounding soil is wetted again, for example by a precipitation event or irrigation, the negative

pressure decreases in the surrounding soil and water flows from the soil into the measurement

volume, whereby the negative pressure in the measurement volume is reduced again. A

manometer or an electronic pressure transducer measures the pressure inside the measurement

volume. Depending on the tensiometer type and design of the tensiometer the pressure is either

read manually or captured automatically, whereby the reading unit as well as the storage unit can

be integrated in the tensiometer or externally executed. Tensiometers are calibrated in a way that

the measured pressure is zero when the porous cup is right at the level of the groundwater

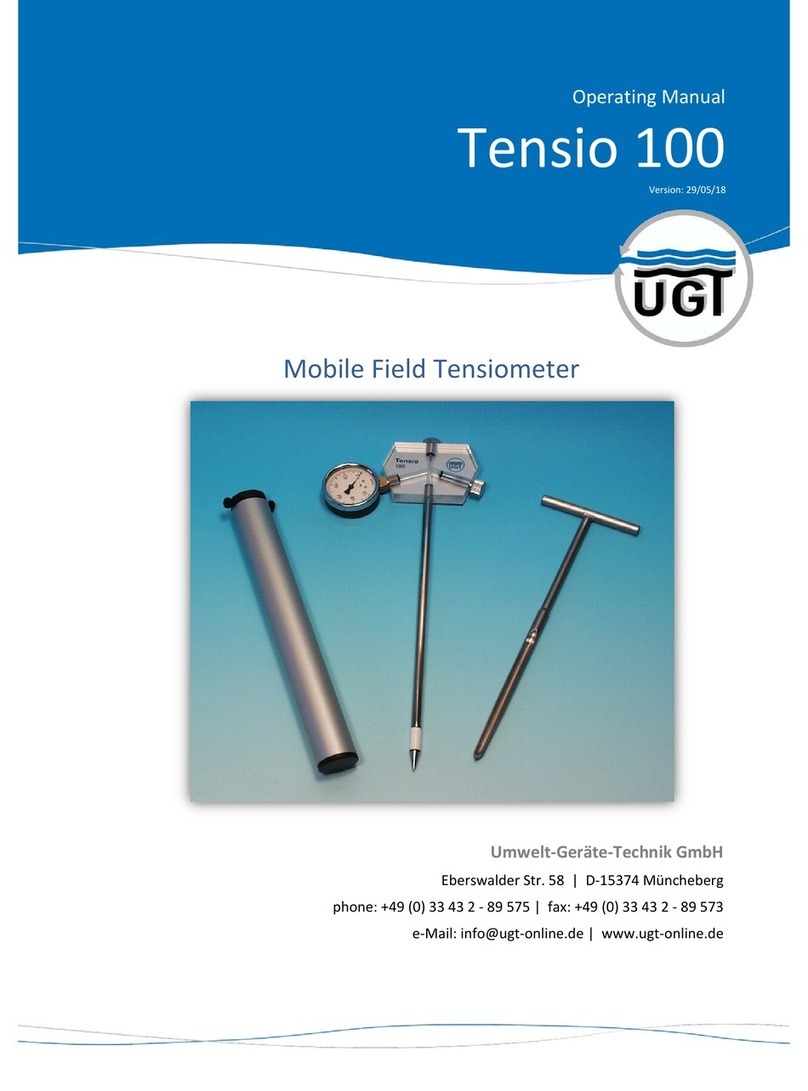

surface. For the Tensio 100 tensiometers this calibration only applies for vertical installation. The

water-filled volume in the standpipe acts as a hanging water column and applies an additional

negative pressure on the pressure transducer. The tension value at the ceramic tip and the

pressure at the pressure transducer differ by this negative pressure. To compensate the influence

of the hanging water column, the pressure transducer is calibrated accordingly. Since this pressure

difference depends on the height difference between ceramic cup and pressure transducer and

therefore on the installation position, deviant installation angles result in incorrect measurements.

2.4. Under Which Conditions Can a Tensiometer Be Used?

Based on the operating principle the measurement range of conventional, water-filled

tensiometers is physically limited by boiling of the water. The boiling point of water (according to

standard 99.6 °C at 1013.25 hPa ≈ 1 bar) is pressure- and temperature-dependent. The boiling

point inside the tensiometer and thus the upper limit of the measurement range depends on the

ambient atmospheric pressure and ambient temperature. At 20 °C and 950 hPa barometric

pressure the water starts boiling at approx. -926.6 hPa. This value also depends on the

temperature-dependent vapor pressure, which rises with increasing temperature. Thus higher

ambient temperatures and lower barometric pressure reduce the measurement range of a

tensiometer. This point may be delayed by boiling retardation. From this moment on the pressure

change is not longer transferred from the water in the soil.

The second physical limit is defined by the air entry point of the ceramic. This point is reached

when the negative pressure is high enough to suck air through the biggest pore of the ceramic. At

this moment the system is not air-tight anymore and the negative pressure suddenly drops.

Subsequently the tensions are about zero and it is not possible to build up a negative pressure

again.

The upper limit of the measurement range of a tensiometer is defined by which point is reached

sooner. If this tension is exceeded and the measurement range is left, the tensiometer stops

working. This is called “drying up” of the tensiometer. To restore the functionality of the

tensiometer it needs to be refilled with water and the tension in the surrounding soil has to be

within the measurement range of the tensiometer. Some systems, such as the Full Range

Tensiometer of UGT GmbH, are not bound to these limits and cannot fall dry due to innovative

operating principles.

The ceramics of the UGT tensiometers have by default an air entry point of at least 85 kPa. This

value slightly varies for every ceramic and depends next to the maximum pore size also on the

state of the ceramic and on substances dissolved in the water. Therefore, a common minimum