The suitability of the boiler

The Ulma ECO 2 can be installed in almost all existing boiler on the market. It is important that he hearth is

so big that he flame does not touch water cooled walls. There should also be room the ash. The smoke flues

of the boiler may not be so narrow that they clog of the ash. Wood boilers have the advantage that they often

have larger room for the ash and are easier to sweep, but even most oil fired boilers are suitable for Ulma

ECO 2. When choosing where to place it a double boiler, make sure if there is a big difference between given

effect between oil and wood. If the difference does not go over 10kw, the pellet burner should be placed in

the wood door if it is possible to open the door with the burner mounted. A boiler meant for high

efficiency more than 40kw can give too low flue gas temperatures (see the chapter chimney).

The chimney should be inspected and possibly test pressured before installation if it has not been operating

before and had continuous maintenance from the local chimney sweeper. At smallest doubt contact your

certified chimney sweeper for inspection. Please note that at too low flue gas temperature the flue gases

may condense with risk of frost damages on the chimney as result. As a rule of thumb you should aim

at a flue gas temperature of at least 70-80°C 1m down in the chimney when the burner is burning,

this goes first of all for brick chimneys or similar material. The choice of flue gas temperature depends

on the design and isolation, a steel chimney or walled chimney with flue lining tube are not as easily

damaged of low flue gas temperatures, provided that possible condensate is drained continuously

from the lowest point of the chimney. This is the task of the installer to control at the installation.

If the chimney is already equipped with a chimney damper this should be completely open at pellet firing.

If possible lock this in some way in open position.

We recommend installation of draft limiter (Back draft door)

The draft limiter shall at installation be adjusted by the installer of approx. -0,10/- 0.15 hPa under pressure.

The draft limiter also helps ventilate the chimney and minimize the risk of condensate problems.

We recommend that it is mounted on the flue pipe out from the boiler. It should be placed so that flue gas

measurements could be made before the draft limiter.

Provide your installation with a flue gas thermometer. Here you can easily see when the temperature rises

and it is time to clean the installation. Suitable temperature rising is approx. 40-50 degrees. But you should

also overlook the capacity of the boiler on hearth and convection part to take care of the ash amount in

good time.The tighter intervals give better fuel economy and efficiency.

At installation the unit should always be adjusted with a flue gas instrument and not only with help from the

human eye. When the burner is in place and has been trimmed in with a flue gas instrument a print of the

control measurements of the installer should be made.

You should be able to read values like CO, O2, CO2, combustion efficiency, draft, flue gas temperature etc.

This analysis should also be made in writing in the two forms that you find at the end of this manual.

One of them you keep and one should be sent to ULMA AB in Svenljunga.

If this is not followed the warranty part of the burner is not valid.

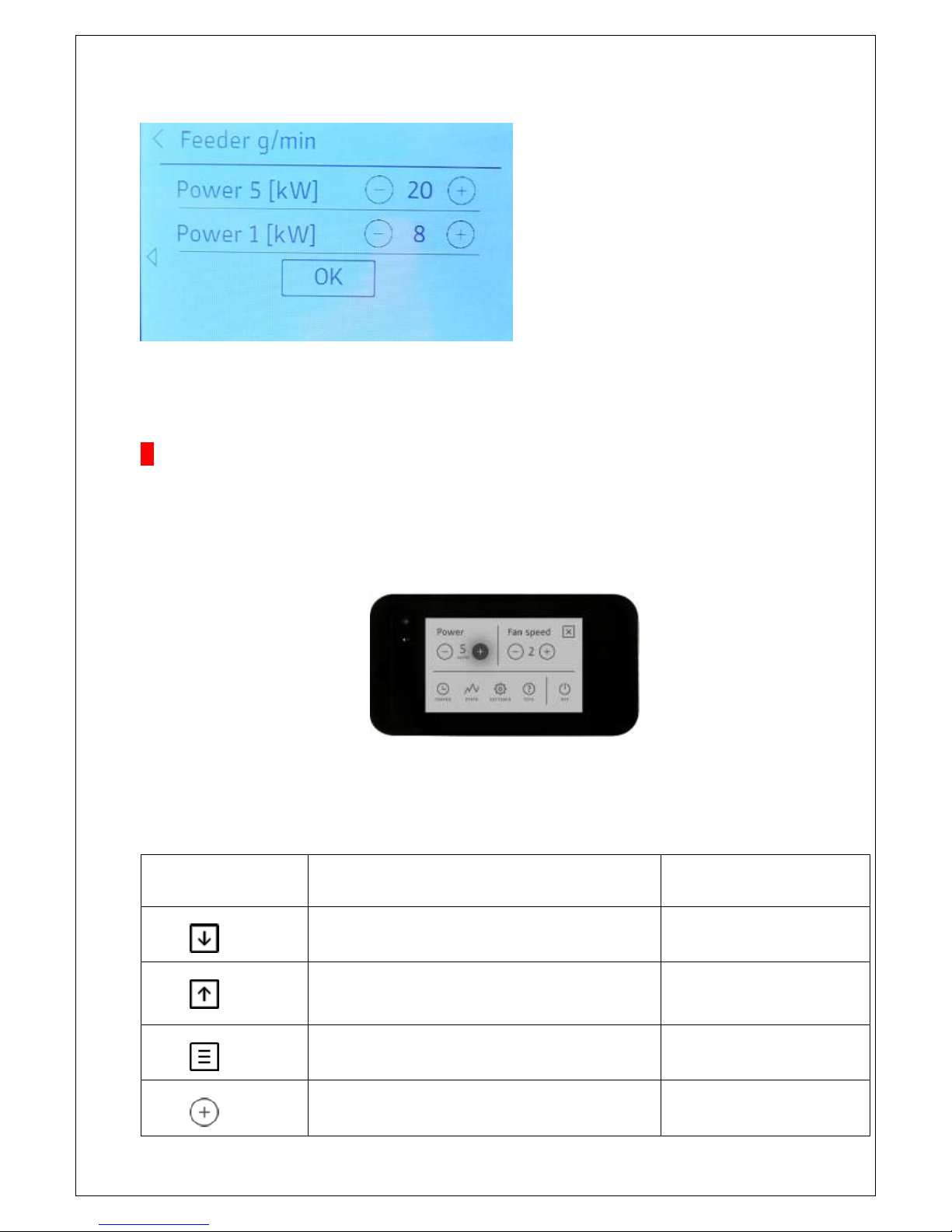

Goal values:

CO2 : 11 %

CO :10 - 300 ppm

O2 : 8 –10 %

hPa : -0,10 / -0,15 (draft)

Combustion efficiency (average): 90-92 %

The burner can handle most kinds of wood pellets between 6-8mm. At change of pellet deliverer the

burner should be adjusted with a flue gas instrument. We also recommend one flue gas analysis per

year to have a better control over the combustion.