INSPECTION:

1. Ensure the safety retractable locks when the lifeline is

pulled sharply, with no slippage, lock-up should be

positive.

2. Labels must be present and fully legible.

3. Check the connecting hooks or carabiners for damage,

distortion, or corrosion, and working condition.

4. Check the housing for distortion, cracks, or other damage

and make sure anchorage point is not distorted or

damaged.

5. Inspect each component of the personal fall protection

system according to the manufactures instructions.

6. The lifeline must fully extend and retract smoothly with

no hesitation or slack on the line.

7. Check the lifeline for cuts, bums, chemical damage,

abrasions, loose strands, or corrosion, the lifeline must

not be damaged.

8. Check for loose or missing screws and bent or damaged

parts.

9. Use of this equipment in areas where surrounding

hazards exist may require additional precautions to

reduce the possibility of injury to the user or damage to

the equipment. Hazards may include, but are not limited

to: high heat, caustic chemicals, corrosive environments,

high voltage power lines, explosive or toxic gases,

moving machinery, or overhead materials that may fall

and contact the user or fall arrest system.

ULTRA-SAFE Safety retractable's are not required a yearly

inspection. If inspection reveals an unsafe or defective

condition, remove the safety retractable lanyard from

service and contact an authorized service station for repair.

NLY ULTRA-SAFE or authorized parties in writing may

make repairs to the equipment.

MAINTENANCE:

Clean the lifeline with water and a mild detergent, rinse

thoroughly and air dry, periodically clean the exterior and

position the safety retractable so water can drain out, clean

labels. An excessive build-up of dirt or other contaminants may

prevent the retractable from operating properly or from fully

retracting causing a potential free fall hazard. Store the safety

retractable in a cool, dry, and clean environment, avoid storing

in areas where chemical vapors exist, or direct sunlight.

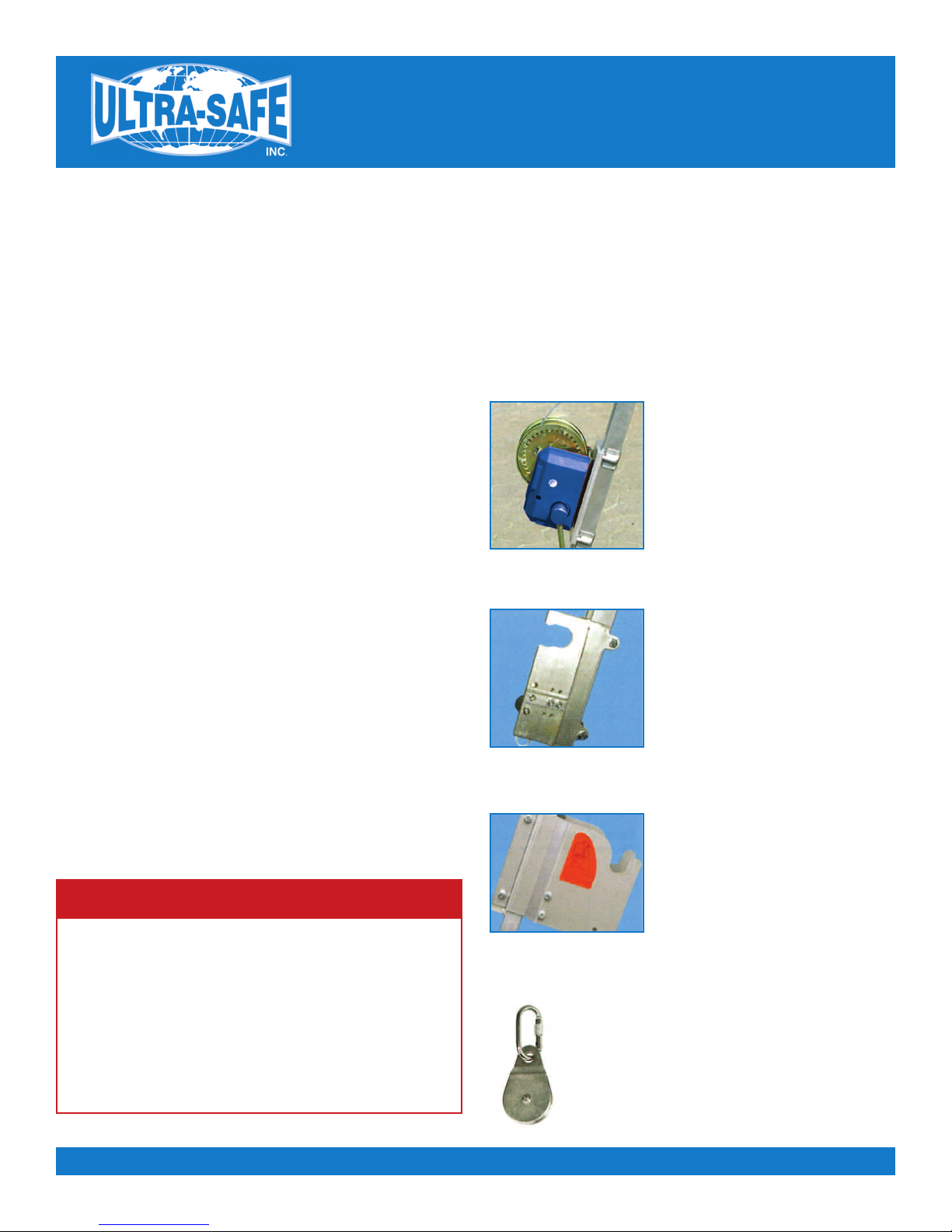

NEW US-HPM65 Winch (personnel & material)

The hand-crank rope winch is

particularly suitable for easy and

jolt-free lifting and lowering of

diverse loads. The maximum

nominal load is 550 lbs.

Galvanized steel rope, rope

length max. 65 feet at 3/16”,

weight 15.4 lbs.

Mounting for US-HRA65 and US-HRA100

Part # US-B65-100

Fast-change mounting for

attaching Ultra-Safe HRA fall

protection equipment, suitable

for attachment to all Ultra-Safe

tripods, weight approximately 4

lbs. (HRA device up to 65 ft. cable

length)

Mounting for US-HRA150

Part # US-B150

Mounting for attaching HRA fall

protection equipment with

100/150 foot cable length suitable

for attachment to Ultra-Safe

tripods.

Top Block Assembly for US1-5000.

Part # US-PC

Stable, smooth running deflection roller

for 3/16” steel rope, is supplied with

carabiner hook. Rustproof and corrosion-

resistant stainless steel version, included

steel carabiner Weight approx. 2.4 lbs.

WARNING!

Training must be conducted without exposing the trainee to a fa

hazard. Training must be repeated periodica y. If the safety

retractab e anyard has been subjected to a fa arrest it must be

removed from service and returned to an authorized service repair

station. Do not a ter or intentiona y misuse this equipment, use

caution when using this equipment around e ectrica hazards, moving

machinery, chemica hazards, and sharp edges. This product is part

of a persona fa arrest system, the user must read, understand and

fo ow the manufacturers instructions for each component.

Instructions must be fo owed for proper use and maintenance, fai ure

to fo ow these instructions may resu t in serious injury or death.

4