300-C Series 1/16/17

www.ultra-tec.com800-851-2961 | 775-885-1443

5. At opposite end post with tensioning terminal, detach

the body from the Hanger Bolt to allow cable slack so

you can perform the next step.

6. Back at post with swageless terminal, push the

cable into the hole in the tting as far as it will go

(approximately 1-1/16”). Twist the cable in a clockwise

direction as you push it into the tting.

4. Pull the cable tightly along the side of the tting and

mark the cable 1-3/16” from the end of the tting

opposite the post. Mark and cut the cable on your mark.

D. Feed/Crimp Cable through Corner Posts

As composite sleeves can be somewhat fragile, it is

recommended to stop and start at corners.

Do not allow a cable to exit a post on an angle; it can

damage the sleeve.

E. Install Swageless Terminal

7. Return to the post with tensioning terminal and

hand turn the body back onto the Hanger Bolt as

far as possible.

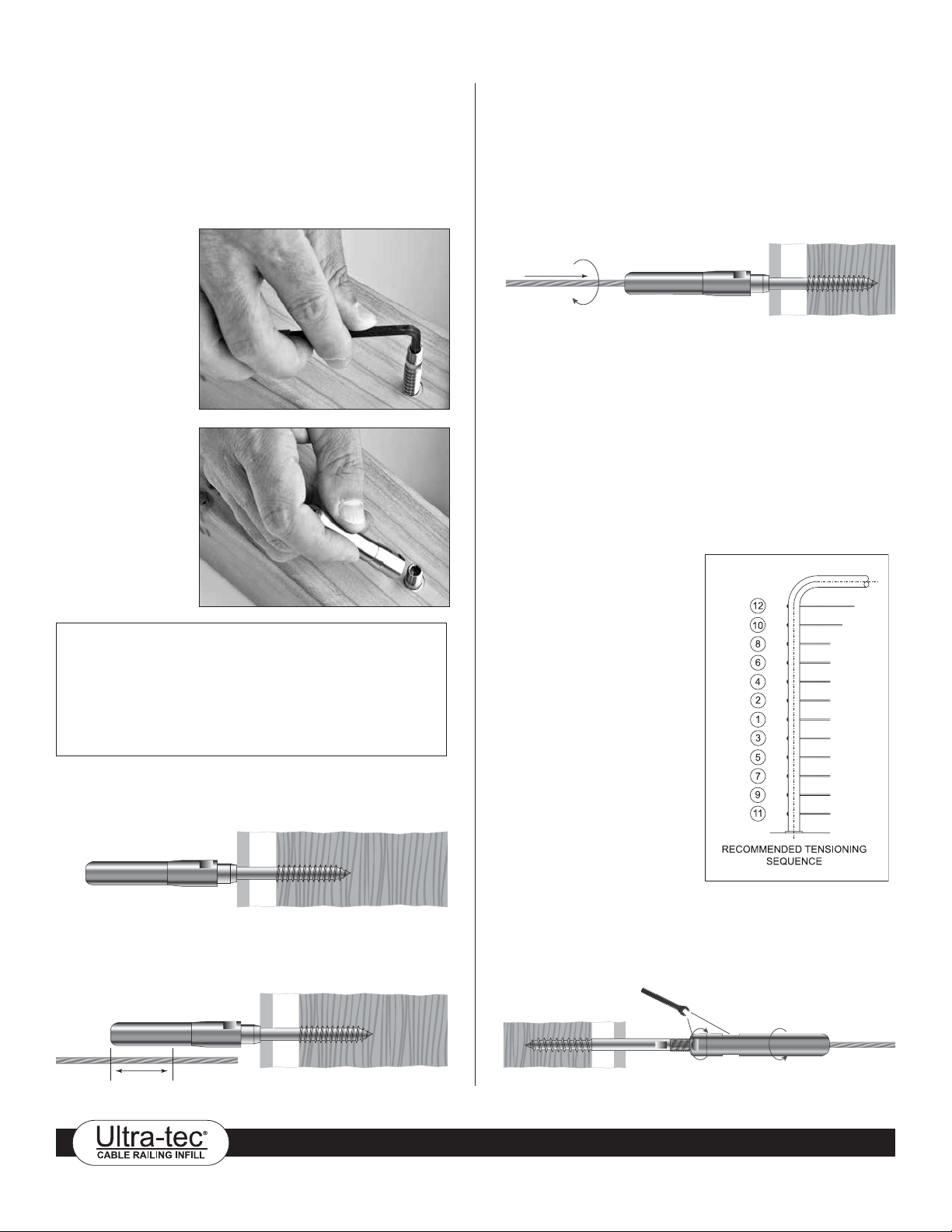

F. Tension Cables

1. Tension the cable by holding it to prevent the cable

from turning while you turn the Adjust-A-Body®with a

7/16” open-end wrench. Be careful to protect the cable

from damage while tensioning the Adjust-A-Body®.

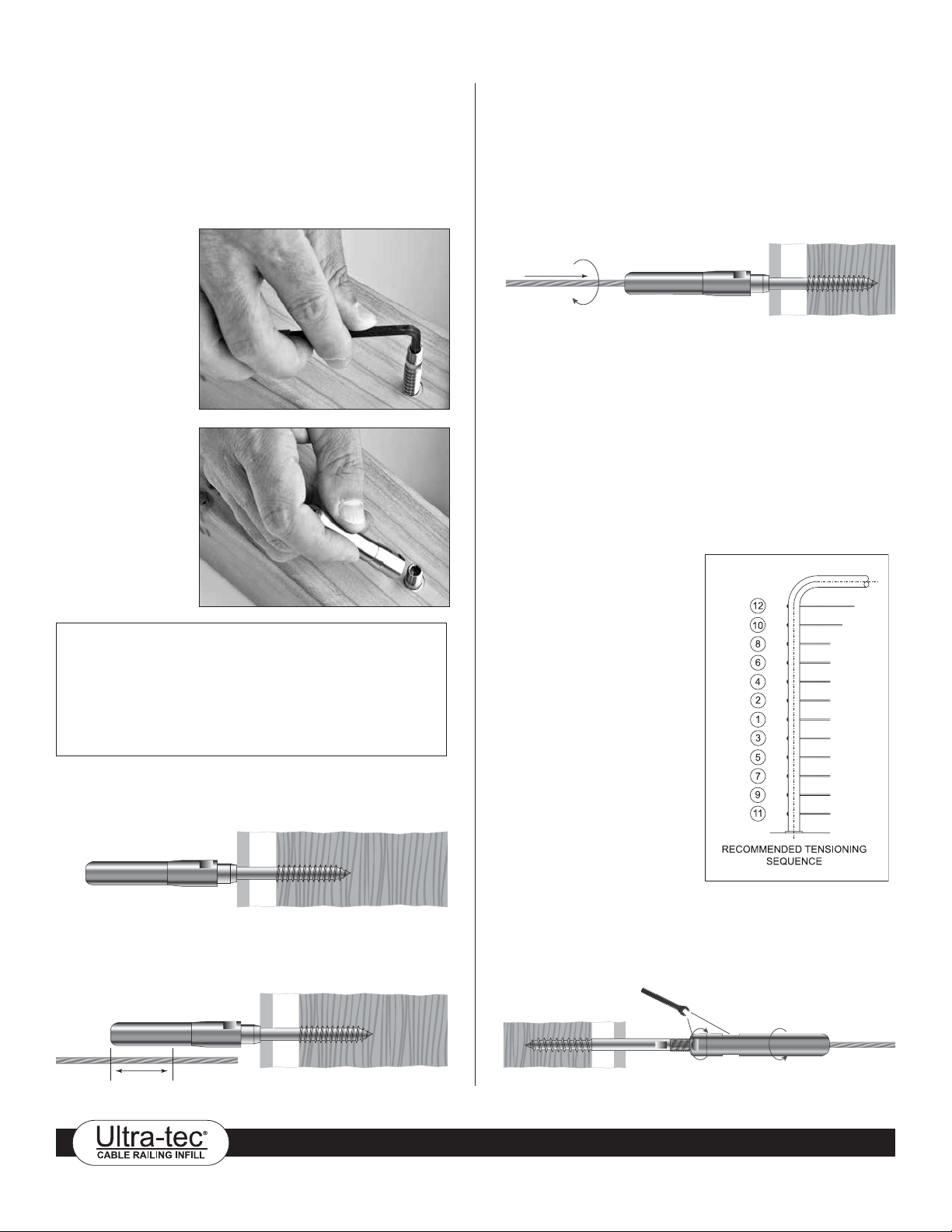

2. Tension all cables to

desired amount in

sequence, beginning

with the center

cables, moving up

and down toward

the top and bottom.

As you tension each

cable, give it a sharp

pull downward

mid-span to help

set the wedges,

then re-tension as

necessary in the

same sequence.

3. While holding the body still with a 7/16” open-end

wrench, turn the lock nut against the body and tighten

with a wrench.

3. Depending on the depth of the composite sleeve,

the Push-Lock® coupler may not be able to sit ush to

the post.

Note: If you have trouble inserting the cable into the tting, it may be

because the locking wedges have become stuck. This is not a defect! Here’s

what you can do to “free the wedges” —

For Pull-Lock®or Push-Lock® ttings for 1/8” cable, using either a PL-KEY or

1/4” diameter bolt, insert the PL-KEY or bolt into the hole and press until

the wedges move freely. Perform the same operation for a 3/16” Pull-Lock®

or Push-Lock®, except use a 16d nail or another tool with 1/8” or smaller

diameter. Anything larger than what is recommended can actually get stuck

inside the tting – NOT what you want!

1. Use a 3/16”

hex wrench

to drive the

lag section

of the tting

into your

pre-drilled

pilot hole.

2. Thread the

Push-Lock®

coupler onto

the lag and

tighten with

7/16” wrench.

1-3/16”

Push