ULTRA TEC CLF-4455 User manual

Power Fog Industrial Fog Burst

v.102020

Operators Manual

Introduction ................................................................ 1

Warning ..................................................................... 1

Safety Precautions .................................................... 1

Technical Specifications ............................................ 2

Technical Drawings ..................................................... 2

Technical Specifications w/ Power Fog Industrial........ 3

Technical Drawings w/ Power Fog Industrial............... 3

Fog Burst Setup.......................................................... 4

Compressed Gases .................................................... 4

Operating Procedure ................................................... 5

Optional Timer/ Duration Remote Operation................ 5

Optional Show Control Remote Operation.................. 5

Show Control Operation .............................................. 6

DMX Operation ........................................................... 6

Maintenance Procedure .............................................. 7

Troubleshooting.......................................................... 7

Warranty ..................................................................... 8

Contact Information ..................................................... 9

Table of Contents

Warning!!

WARNING!!

1. Do not touch, place hands or expose skin within 20”(50cm) of the discharge nozzle.

2. Do not remove the outer case.

3. Persons suffering from asthma or allergenic sensitivity may experience irritation, discomfort or

allergic symptoms when exposed to fog effects.

4. Ensure that this unit is grounded at all times. Failure to do so may result in serious injury.

5. Use Ultratec Special Effects fluids only.

SDS is available at www.ultratecfx.com

1. Ensure that any operation of the machine is supervised by suitably trained and authorized personnel.

2. Do not modify the machine or use a machine which has been damaged in any way.

3. Allow sufficient air circulation around the machine at all times.

4. Protect the machine from direct weather effects and wet locations. Suitable for dry locations only.

5. Only use fog fluid by Ultratec Special Effects.

6. Do not continue to produce fog in an enclosed area when visibility is reduced below 20”(50cm).

7. Avoid direct fog output continuously at persons, structures or objects within close proximity of

the discharge nozzle.

8. Ensure that adequate exhausting arrangements are available in the event of an emergency.

9. Do not place hands or exposed skin within the first 20”(50cm) of the discharge nozzle at any

time during fog production.

10. Fog effects can trigger smoke alarms and detectors. Please take suitable precautions to

prevent false alarms.

Important Safety Instructions:

WARNING!!

Safety Precautions

WARNING!!

Introduction

1www.ultratecfx.com

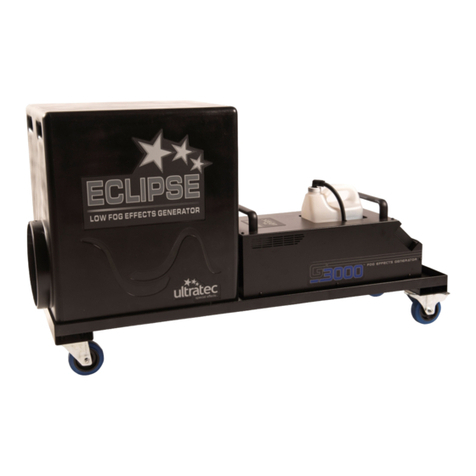

Create a Large Fog Burst with a Power Fog Industrial, the Fog Burst attachment is controlled by the Standard

On-Board DMX controls and the Auxiliary AC outlet on the rear of the machine. This complete package allows

for amazing control while offering similar effects to Cryogenics from a fraction of the operational costs.

***Power Fog Industrial Fog Machine sold separately

Technical Drawings

Technical Specifications

Model: Power Fog Industrial Fog Burst

CLF-4455 Power Fog Industrial Fog Burst 110V

CLF-4487 Fog Burst for PFI/PFI 9D 220V

Length: 5 in / 13 cm

Width: 7 in / 18 cm

Height: 2 in / 5 cm

Net Weight: 3 lbs/ 2 kgs

Power Rating: 120 Volt A.C. 50/60 Hz. 1 A.

220 Volt A.C. 50/60 Hz. 0.5 A.

Ultratec Special Effects Fog Burst Air Requirements in SCFM:

Pressure-----Fog Burst

20 PSI----------8

40 PSI---------11

60 PSI---------15

80 PSI---------19

90 PSI---------22

100 PSI---------25

The Fog Burst gives 15 times output or about 375 CFM @ 100 PSI

Approvals: This product has been certified to CSA/UL Standards by QPS Canada Inc

NOTE: These specifications are for the Fog Burst only. For specifications with the Power Fog

Industrial see next page.

11.24

10.22

5.34

7.68

7.68

3www.ultratecfx.com

Technical Drawings

Technical Specifications

Power Fog Industrial and Fog Burst

Length: 15.64 in / 39.7 cm

Width: 18.73 in / 47.6cm

Height: 9.88 in / 25 cm

Net Weight: 32 Lbs/ 14.5 kg

Power Rating: 120 Volt A.C. 50/60 Hz. 14 A.

220 Volt A.C. 50/60 Hz. 8 A.

Approvals: This product has been certified to CSA/UL Standards by QPS Canada Inc

18.73

9.88

15.64

15.64

15.14

www.ultratecfx.com 4

Fog Burst Setup

The compressed gas does not have to be air, you can use nitrogen or CO2 gas. CO2

is liquid in the tank so you can get a large volume from a small tank and regulator. A

pressure regulator to drop the pressure is required. The number of cycles would

depend on the volume of your tank. We offer a regulator and hose accessory to

facilitate this. (see below).

CXP-1968 CO2 Regulator with 5 foot hose & High flow quick disconnect.

This unit is used to supply regulated CO2 gas to run devices that require a source of

compressed gas. Shown here on a 5 pound CO2 tank, (tank is not included.)

To connect the Fog Burst to the Power Fog Industrial.

1) Remove the 4" ducting adapter from the front/side of the Power Fog Industrial /9D (if

equipped)

2) Position the Fog Burst on front of the Power Fog Industrial with the valve assembly

facing upwards.

3) Line up the three holes on the mounting bracket with the three mounting holes around

output nozzle of the fog machine.

4)Install with the self tapping screws provided with the Fog Burst

5) Connect your compressed gas source to the valve (remember to use a gas pressure

regulator if your source gas pressure is greater than 100 PSI).

6) Connect the power cord from the Fog Burst to the Auxiliary port on the back of the

Power Fog Industrial/9D.

Compressed Gases

Operating Procedure

Optional Timer/ Duration Remote Operation

The Timer/ Duration Remote offers Duration, Interval, Variflow and fog

on/ off controls.

Timer/ Duration Remote LED Indicator

The Timer/ Duration Remote Handset was designed to indicate

operation modes. These are as follows:

Slow Flashing Light: Indicates unit is not ready to operate but still in

heating mode, fog is not available at this point.

Quick Flashing Light: Indicates unit is ready to operate but still in

heating mode, some fog is available at this point.

Solid Light: Indicates that the unit is ready to fog at full output.

Triple Pattern Flashing Light: Indicates that the unit is in an over

temperature condition and has shut down.

DURATION INTERVAL

FOG

VARIFLOW

Smoke OFF/ON Switch

Flow Dial

Duration Dial Interval Dial

Optional Timer/ Duration Remote

LED

5www.ultratecfx.com

The Show Control Remote Handset LED was designed to indicate operation modes. These are as

follows:

Slow Flashing Light: Indicates unit is not ready to operate but still in heating mode, fog is not available

at this point.

Quick Flashing Light: Indicates unit is ready to operate but still in heating mode, some fog is available

at this point.

Solid Light: Indicates that the unit is ready to fog at full output.

Triple Pattern Flashing Light: Indicates that the unit is in an over temperature condition and has shut

down.

No Light: Indicates problems; a loss of power or remote is not connected. If these fail to correct the

problem, contact your local Ultratec Special Effects dealer.

Optional Show Control Remote Operation

No Light: Indicates problems; a loss of power or remote is not

connected. If these fail to correct the problem, contact your local Ultratec Special Effects dealer.

Note: To operate the Fog Burst using the Timer/ Duration Remote, the DMX Address must be set on

555. A show Control Remote and Timer/ Duration Remote cable may be extended

from the machine and operated effectively away from the Power Fog Industrial/9D. The maximum

recommended cable length is 225 Feet.

1) Power up fog machine and wait until fully heated (solid red LED on remote).

2) Turn Flow dial to desired fog output level.

3) Turn Duration dial above 50% to turn on Fog Burst.

4) Flip Smoke OFF/ON switch to ON position to start producing fog effect.

5) Reverse steps to turn OFF effects.

Optional Timer/ Duration Remote Operation cont.

C123

DRY CONTACTS

VARIFLOW

SMOKE

OFF ON

Contacts

Variflow

LED

Smoke

OFF/ON

www.ultratecfx.com 6

DMX Operation

1. Attach a DMX signal to the DMX IN 5 pin connector on the rear of the PFI9D.

A terminator may be required on the DMX OUT connector in some applications.

2. Select a valid DMX address on the numerical selectors for the base address of the fogger.

3. 2 consecutive address will be required. Base DMX= fog rate controlled 0-100%, DMX+1=Fog Burst

power on above 50%.

NOTE: A 3rd DMX Channel (DMX+2) = air on above 50%.(If PFI9D is equipped with optional air

option.).

4. The Valid DMX LED is on solid if good DMX signal is present. DMX control overrides hand remotes.

Slow or irregular flashing indicates poor DMX data.

Show control is achieved by connecting a “Dry” or zero voltage contact to the show control terminals. The

Power Fog Industrial 9D requires no power to signal the fog, only one set of contacts that close for the

entire fogging cue.

For Show Control Operation, the DMX Address must be set on 555. Closing the Show Control Remote

terminals with dry contacts, triggers the following machine functions:

C + 1 = Fog On/ Off w/ Variflow

C + 2 = Fog Burst On

C + 3 = Air Option

Show Control Operation

C123

DRY CONTACTS

VARIFLOW

SMOKE

OFF ON

Contacts

Variflow

LED

Smoke

OFF/ON

Maintenance Procedure

Troubleshooting

Check gas pressure: Is compressed gas getting to the solenoid valve?

Check that the air line is connected to a suitable air source at the required pressure.

Power to solenoid: Is power getting to the solenoid?

Check that Fog Burst is connected to the Power Fog Industrial/9D power source.

If using DMX: Check that the second DMX channel being used to control the auxiliary output is at a minimum of

50%.

Ensure that DMX address is set to 555.

If using hand held remote; ensure Duration dial is above the 50% mark.

If using show control remote; ensure a good connection between C + 2 on the terminal block.

Exterior

The casing of the Fog Burst is steel with a powder paint coating. To clean simply disconnect power source and

wash with a cloth and mild soap and warm water.

7www.ultratecfx.com

Warranty

Please remember to include the RA Number on all items being shipped

for repairs.

To request a Return Authorization number please refer to our website - instructions below:

1) www.ultratecfx.com

2) Click on the Fog & Atmospheric Icon

3) Click on the REQUEST RMA Tab along the top of the screen

4) Fill in the required information

5) Click "Submit" button

If you have any questions or require assistance please contact service at

519-951-3355/866-534-5557 or by email at [email protected].

Hardware products come with a five-year warranty on parts and labor. If the unit in question has a material

defect or fault that is caused in manufacturing, Ultratec Special Effects will provide free parts and labor to

remedy the equipment. Ultratec Special Effects service department must be advised in a timely manner

after defect appearance and the date of warranty request must be within five years of sale/purchase. Proof

of sale and/or proof of purchase will be required for warranty to take effect.

Warranty service will be performed as follows: faulty parts will be repaired or replaced with the same or

comparable parts, based on availability. Freight to our facility for warranty requests will be prepaid by the

user/dealer. Upon completion of the repair, Ultratec Special Effects will return the unit via the most

economical means available. Should you require the item express-returned, the user/dealer is responsible

for indicating this request and for any difference in freight cost.

Warranty will be voided, and customer will lose all rights guaranteed by the warranty if any of the following

are observed/occur:

If any non Ultratec Special Effects fluid is used at any point of operation.

If any adjustments or repairs are done to the machine in question by repair technicians not authorized by

Ultratec Special Effects.

If our repair technicians observe any signs of incorrect handling/treating of machine in question.

Warranty services do not cause an extension of the warranty nor does a repaired product start a new

warranty. This warranty only applies to the product supplied by Ultratec Special Effects, Ultratec Special

Effects is not responsible for any losses, costs, or damages from the use of a defective product.

Any additional costs incurred are the responsibility of the Dealer and/ or the customer.

An RA (Return Authorization) number must be noted on the outside of each box being returned to our

facility. Any package(s) without an RA number clearly marked, will not be accepted by our receiving

department.

Export Distributors are required to carry out the warranty repair, parts will be supplied by

Ultratec.

Please do not forget to remove any liquid from the machine when sending in for repair.

www.ultratecfx.com 8

This manual suits for next models

1

Table of contents

Other ULTRA TEC Fog Machine manuals

ULTRA TEC

ULTRA TEC LSX User manual

ULTRA TEC

ULTRA TEC G3000 User manual

ULTRA TEC

ULTRA TEC 9D User manual

ULTRA TEC

ULTRA TEC G3000 User manual

ULTRA TEC

ULTRA TEC G3000 User manual

ULTRA TEC

ULTRA TEC LSG PFI-9D User manual

ULTRA TEC

ULTRA TEC CLF2460 User manual

ULTRA TEC

ULTRA TEC Stage Fogger DMX User manual

ULTRA TEC

ULTRA TEC Ultra Handy Fogger User manual

ULTRA TEC

ULTRA TEC IceJet III User manual