Page 1

SELF-STANDING FAMILY TENT

UNHCR Item No 00008154

Optimal Shipping / Container Information

Weight and Volume

Expected Life Span

Packing

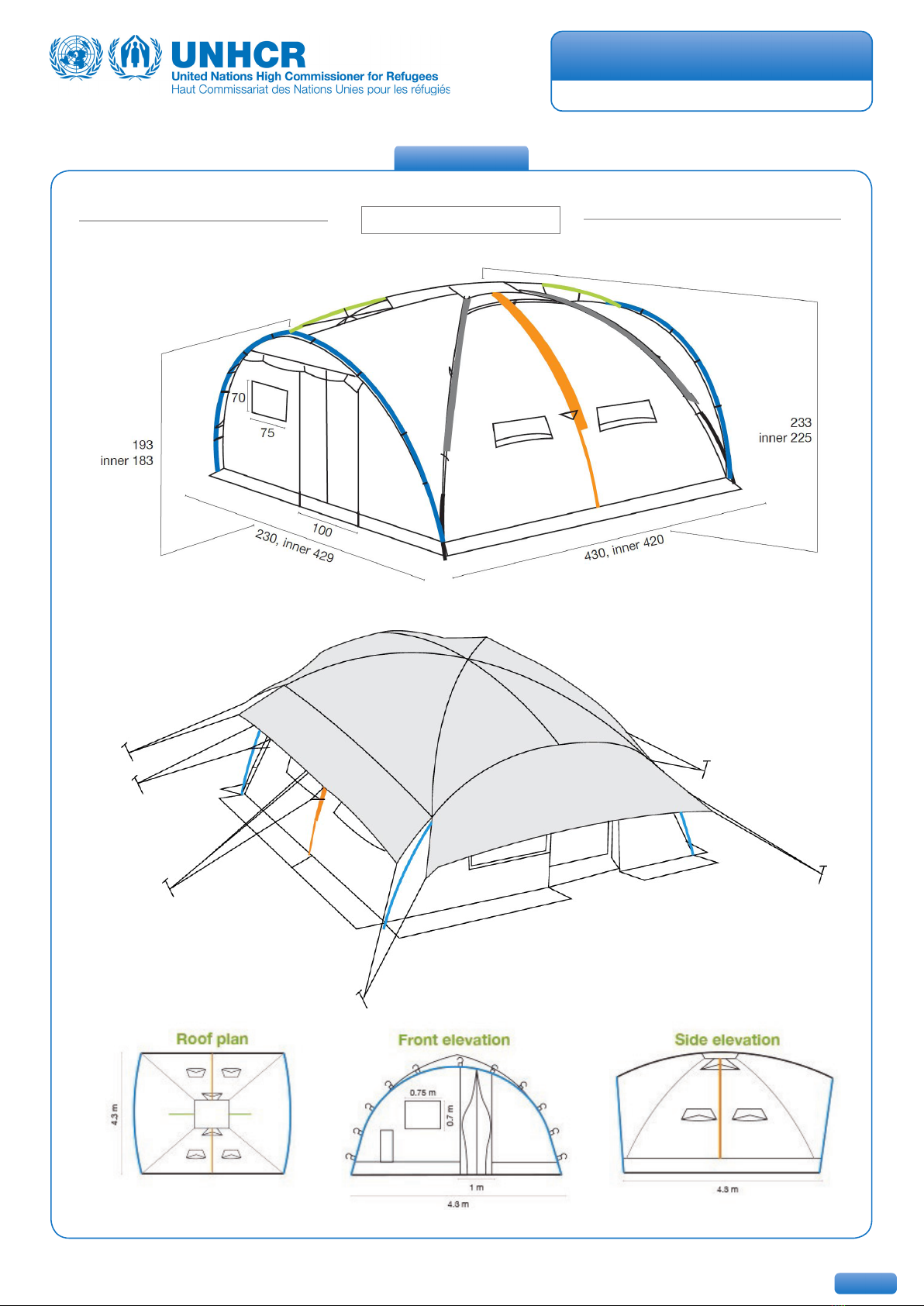

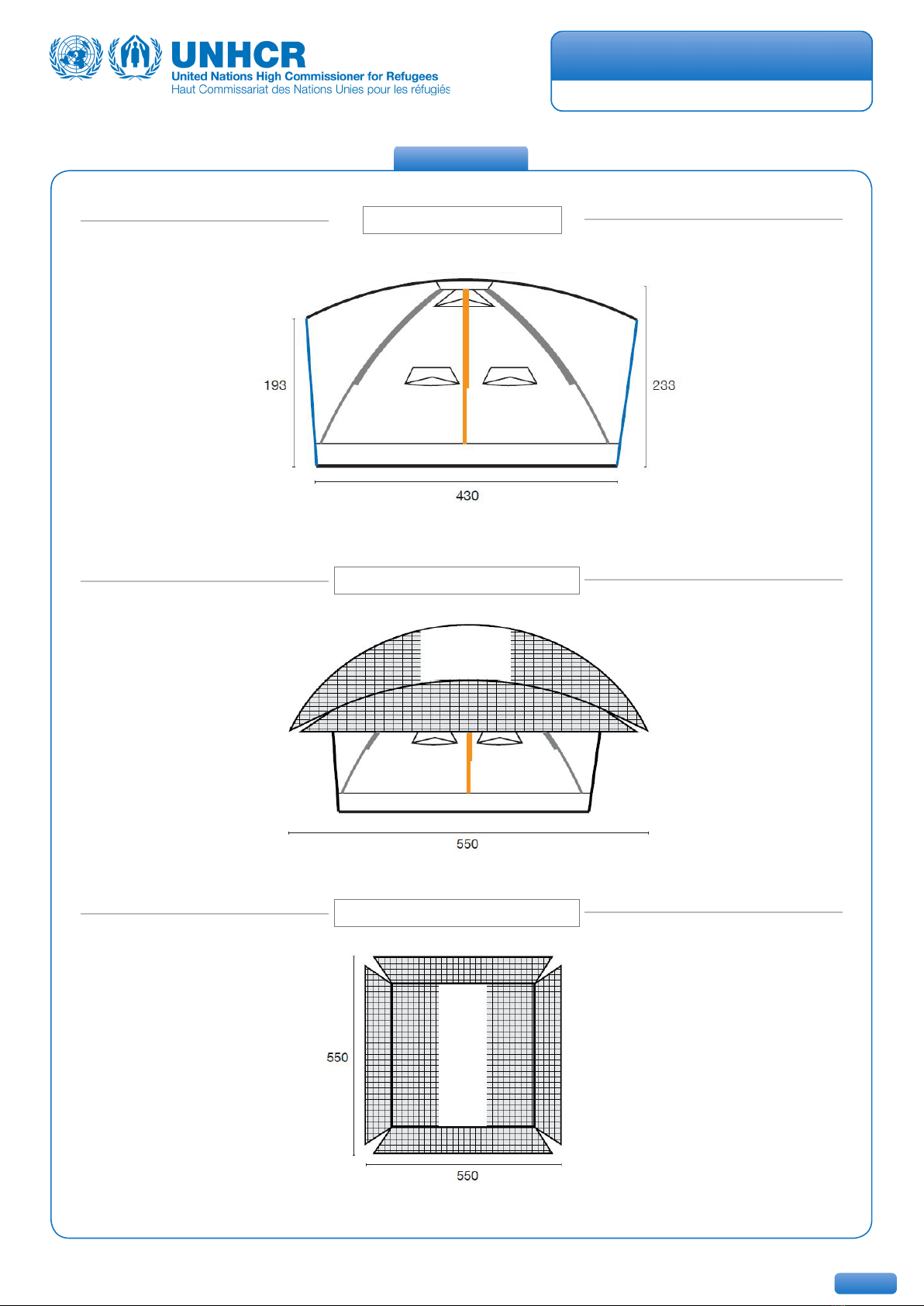

The Self-Standing Family Tent has 18,5 m2 of main oor area.

It is the standard tent used by UNHCR and is suitable for a family of ve people.

It follows the recommended minimum living area for hot and temperate climates

(3.5 m2 per person), and provides additional space for cold climates.

Shelter specialists developed the tent’s technical specications to guarantee a

product t for human use in all climates, with an appropriate outdoor life span,

at a minimal cost.

The technical specications for this tent are generic. This ensures that the

product can be manufactured by different suppliers in various countries, with

common technical know-how and standard equipment from the tent industry.

UNHCR purchases family tents through international tender processes and

establishes frame agreements (long term agreements) with manufacturers

that have completed validation / qualication of Self-Standing Family Tent

samples in one of the UNHCR approved laboratories. Self-Standing Family

tents are subject to random and continuous quality control throughout the frame

agreement duration period.

For the validation / qualication of Self-Standing Family Tent samples, it

is advisable to rst ensure adherence to the main material specications.

Information about approved technical laboratories can be obtained from the

UNHCR Supply Management Service in Budapest.

Self-Standing Family tents should comply with all technical requirements, criteria

and parameters described in this document, and as detailed in the technical

specications section.

Information for laboratory testing:

To complete the validation / qualication of the Self-Standing Family Tent

samples, three (03) complete samples are to be sent to one of the UNHCR

approved laboratories for testing and make up checking. One sample will be

used for material testing and the remaining two for a rain test and a large scale

re test (if needed). A product is only acceptable if all criteria are passed on the

same sample.

Self-Standing Family Tents are designed as a short-term shelter solution,

particularly as a support during emergency situations, and is not a substitute

for more permanent shelters. It is expected that family tents should have a

minimum lifespan of one year, maintaining its shelter and waterproof capacities

in all types of climates.

Shelf life: the tent has a minimum shelf life of ve years, under normal storage

conditions, in dry, clean, and ventilated warehouses. It should be elevated from

the ground (on pallets or pallet racks), not piled, not in containers or in tented

warehouses. Packed tents are sensitive to rain and moisture.

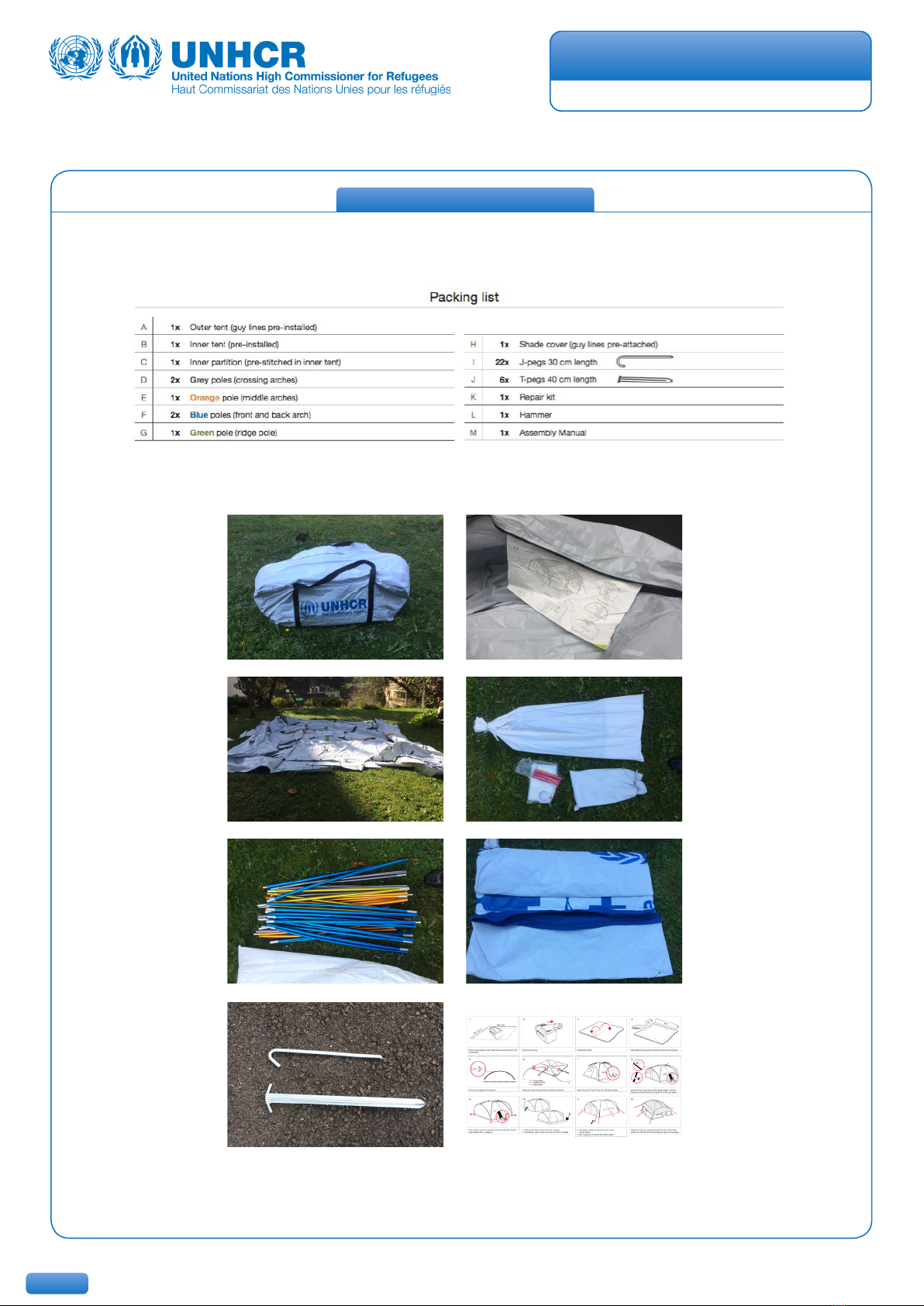

One tent with all accessories are packed into a master bag that ensures

its’ protection from dirt and moisture. The master bag is made from woven

polyethylene (PE) fabric of 190 g/m2 identical to that used for the main tent

cover.

The international standard warning sign ‘protect from water’ should be printed

on the outside of the package. The buyer’s markings are printed on the

outside in indelible ink.

The bag must be a PE bag with the dimensions 115 cm x 55 cm x 45 cm, with

a zip closure. The bag must be secured with two webbing straps, each with a

self-locking buckle that will not slide during transportation. Each strap provides

two handles. The straps must not be sewn to the bag. All other aspects are as

per standard packaging instructions. The palletised goods must not exceed the

pallet length and width.

Gross weight per unit: approx. 52 kg

Gross volume per unit: approx. 0.285 m3

General Information and Description

Item Application Sample

With pallet

• 96 tents per 20’ GP

• 240 tents per 40’ DC

• 240 tents per 40’ HC

Without pallet

•150 tents per 20’ GP

• 312 tents per 40’ DC

• 364 tents per 40’ HC