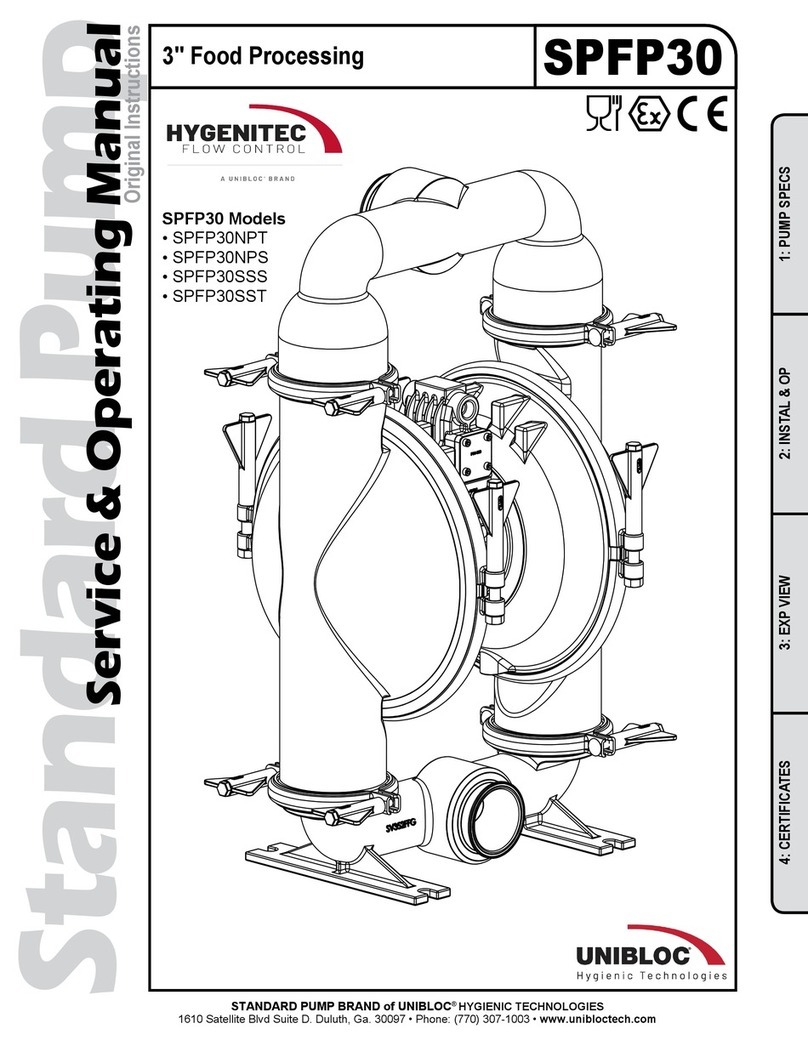

Contents

3

www.unibloctech.com

Contents

0. General ........................................................................................................................................... 5

Introduction .................................................................................................................................... 5

Safety Notice ................................................................................................................................. 5

Declaration of conformity ............................................................................................................... 6

Training .......................................................................................................................................... 6

Limitations of use ........................................................................................................................... 6

0.5.1. Health Hazard Warning ......................................................................................................... 7

ATEX Safety Information ............................................................................................................... 8

0.6.1. General .................................................................................................................................. 8

0.6.2. ATEX Directive 2014/34/EU (Equipment for Explosive Atmospheres) ................................. 8

0.6.3. Personnel qualifications and training ..................................................................................... 8

0.6.4. Products used in potentially explosive atmospheres ............................................................. 8

0.6.5. Scope of compliance ............................................................................................................. 9

0.6.6. Marking .................................................................................................................................. 9

0.6.7. Avoiding excessive surface temperatures ............................................................................. 9

0.6.8. Pump media temperature ...................................................................................................... 9

0.6.9. Preventing the build-up of explosive mixtures ..................................................................... 10

0.6.10. Preventing sparks ................................................................................................................ 10

0.6.11. Preventing leakage .............................................................................................................. 10

0.6.12. Maintenance to the double diaphragm pump to avoid potential hazards ............................ 10

0.6.13. Additional safety instructions ............................................................................................... 11

1. Installation ...................................................................................................................................12

Packaging and Shipping Inspection ............................................................................................ 12

Storage ........................................................................................................................................ 12

Installing the Slimline Pump ........................................................................................................ 12

1.3.1. Foundation ........................................................................................................................... 12

1.3.2. Connection of suction and delivery pipes ............................................................................ 13

1.3.3. Connection of Air Pipes ....................................................................................................... 14

1.3.4. Air Pressure ......................................................................................................................... 14

1.3.5. Air condition ......................................................................................................................... 14

Example of Installation................................................................................................................. 14

2. Operation .....................................................................................................................................15

Before starting the pump ............................................................................................................. 15

Operation of pump ....................................................................................................................... 15

Noise levels ................................................................................................................................. 15

Recommendations for Best Pump Performance ......................................................................... 15

3. Maintenance.................................................................................................................................16

Routine inspection ....................................................................................................................... 16

Complete inspection .................................................................................................................... 16

Chapter Title Page no.