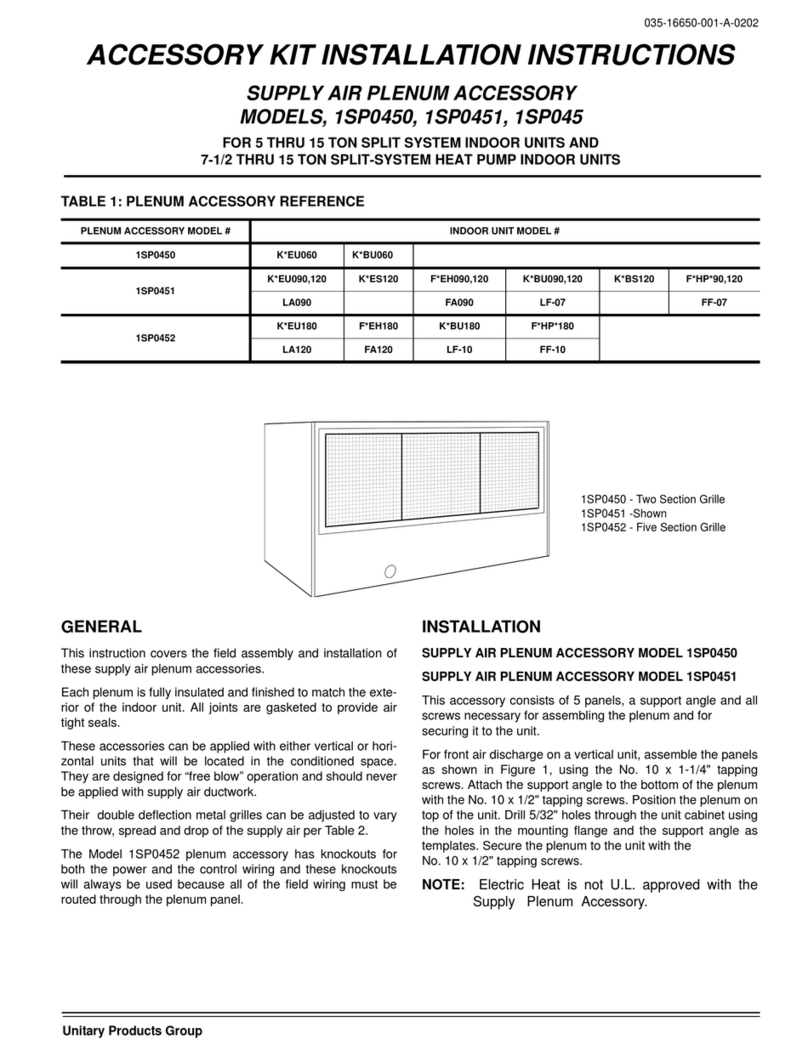

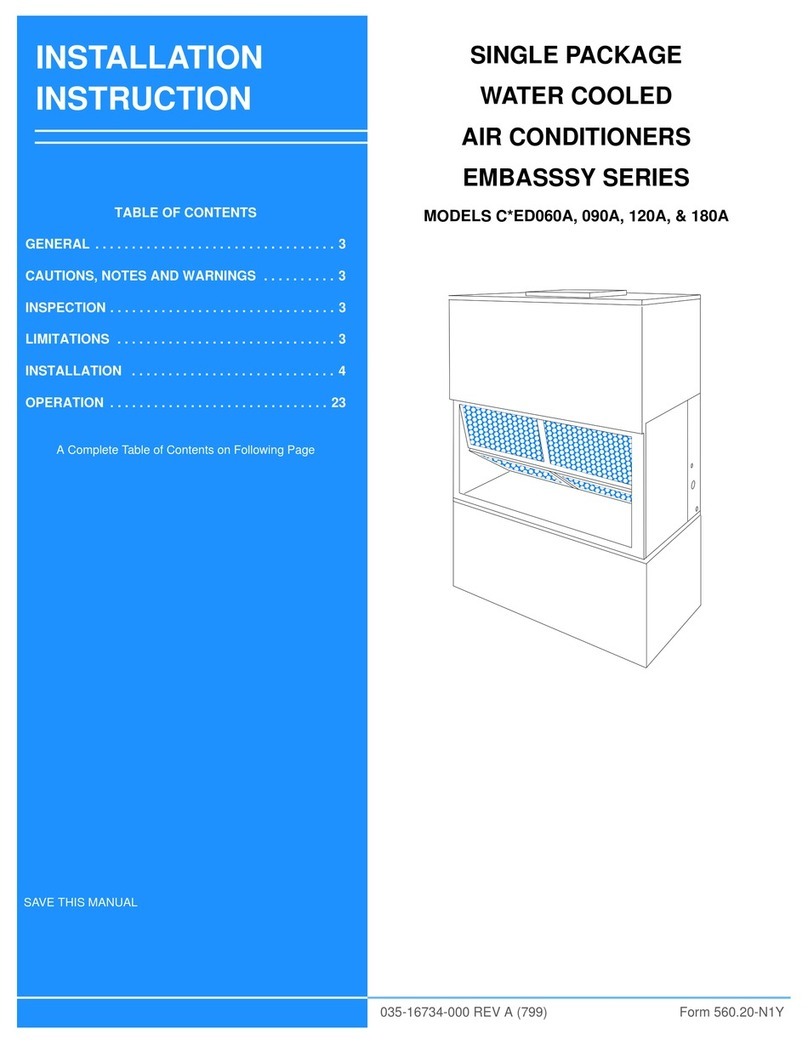

FIXED OUTDOOR AIR INTAKE DAMPER

This damper is shipped inside the return air compartment. It is

completely assembled and ready for installation. A damper

baffle inside the hood is adjustable to provide variable

amounts of outdoor air intake on units that are not provided

with an economizer or a motorized damper option. Refer to

Figure 3.

Gasketing and mounting screws are provided in a parts bag

attached to the hood assembly. Apply gasketing to the three

flangesurfaces on the hood priorto installing the hood. Extend

gasketing 1/4 inch beyond the top and bottom of the two side

flanges to insure adequate sealing.

Adjusting the damper to the desired air flow may be done

before mounting the hood into position or (after installation) by

removing the front hood panel or the screen on the bottom of

the hood. Damper baffle in position 1 will allow approximately

10%recirculatedairflow, position2approximately15%and,to

allow approximately 25%, remove the damper baffle.

On units with bottom return air applications, install the damper

assembly over the opening in the side return air access panel.

Remove and discard the opening cover and the covering over

the hood mounting holes (used for shipping) before installing.

Secure with the screws provided.

On units with side return air applications, install the damper

assembly on the return air ductwork as close to the unit as

possible. Cut an opening 16 inches high by 18 inches wide in

the ductwork to accommodate the damper. Using the holes in

the hood flanges as a template, drill 9/64 inch dia. (#26 drill)

holes into the ductwork and secure with the screws provided.

CAUTION: If outdoor air intake will not be required on units

with bottom return air applications, the damper

assembly should still be mounted on the side

returnairaccesspanel,pertheinstructionsabove,

to insure moisture is not drawn into the unit during

operation. The covering over the mounting holes

onlyneedberemoved.Do not remove the opening

cover.

CONDENSATE DRAIN

Plumbing must conform to local codes. Use a sealing

compound on male pipe threads. Install a condensate drain

line from the one-inch NPT female connection on the unit to an

open drain.

An alternate drain connection (one-inch NPT female coupling)

is provided inboard on the same centerline as the exterior

location.

NOTE: The condensate drain line MUST be trapped to pro-

vide proper drainage. See Figure 4.

COMPRESSORS

Unitsareshippedwithcompressormountingsfactory-adjusted

and ready for operation.

CAUTION: Do Not loosen compressor mounting bolts.

FILTERS

Two-inchfiltersaresuppliedwitheachunit.Filtersmustalways

be installed ahead of the indoor coil and must be kept clean or

replaced with same size and type. Dirty filters will reduce the

capacity of the unit and will result in frosted coils or safety

shutdown.Minimum filter areaandrequiredsizesareshownin

Table 4.

SERVICE ACCESS

Access to all serviceable components is provided by the

following removable panels:

•Compressor compartment

•Electric Heat compartment

•Side Supply & Return Air compartments (Two panels)

•Blower compartment (Three panels)

•Main control box

•Filter compartment

•Outdoor Air compartment (Two panels)

Refer to Figure 9 for location of these access panels.

CAUTION: Make sure that all screws and panel latches are

replaced and properly positioned on the unit to

maintain an air-tight seal.

THERMOSTAT

The room thermostat should be located on an inside wall

approximately 56 inches above the floor where it will not be

subject to drafts, sun exposure or heat from electrical fixtures

or appliances. Follow manufacturer's instructions enclosed

withthermostatfor general installationprocedure.Colorcoded

insulated wires (#18 AWG) should be used to connect

thermostat to unit.

POWER AND CONTROL WIRING

Field wiring to the unit must conform to provisions of the

National Electrical Code, ANSI / NFPA No. 70 (in U.S.A.),

currentCanadianElectricCode(CEC)CSAC22.1 (inCanada)

and/orlocalordinances.Theunitmustbeelectricallygrounded

in accordance with NEC and CEC (as specified above) and/or

local codes. Voltage tolerances which must be maintained at

the compressor terminals during starting and running

conditions are indicated on the unit Rating Plate and Table 1.

The internal wiring harness furnished with this unit is an

integral part of a ETL and CGA design certified unit. Field

alteration to comply with electrical codes should not be

required.

4 Unitary Products Group

530.22-N5W

FIG. 3 - FIXED OUTDOOR AIR DAMPER

FIG. 4 - RECOMMENDED DRAIN PIPING