JOHNSON CONTROLS

6

FORM 145.26-IOM1 (908)

1. PREPARING TO INSTALL

A. Literature

After installing the unit; give this Installer’s Information

Manual, and the Warranty card to the end user. If you

need help on any of the installation instructions or other

matters relating to this equipment, contact the ofce

where you bought the unit. You may also refer to the

unit rating plate for a contact name.

2. IMPORTANT SAFETY RULES

Read and exactly follow these rules.

Failure to do so could cause improper

furnace operation, resulting in damage,

injury or death.

a) DO NOT install this equipment outdoors or in a

mobile home, trailer or recreational vehicle. It is not

design-certied for these installations. This furnace

is suitable for a home built on site or manufactured

home completed at nal site.

b) DO NOT install in a corrosive or contaminated

atmosphere.

c) DO NOT use this equipment for temporary heating

of buildings or structures under construction.

d) Always install duct system with this equipment.

Be sure duct system has external static pressure

within allowable operating range.

e) Completely seal supply and return air ducts to

the unit casing. Duct work must run to an area

outside the space containing the unit. Seal duct

work whenever it runs through walls, ceilings or

oors. See Section 11 for more information.

3. MEETING CODES

Before installing unit, make sure you know all

applicable codes. National, state and local codes

may take precedence over any instructions in this

manual. Be sure to consult:

- Authorities having jurisdiction over air-conditioning

and heating installations;

- Local code authorities for information on electrical

wiring.

4. UNPACKING

a) Check the unit for indications of damage in ship-

ment. Notify the Transportation company of any

damage and note the damage on the shipping

receipt.

Rough handling may dislocate internal

components.

b) Allow the shipping base to remain with the unit until

it is ready to be set in its nal location.

c) Rotate blowers to assure free movement.

d) The compressor is mounted on neoprene isolators

with metal spacing sleeves inside and secured

with nuts, which must be snug against the metal

spacer sleeves.

e) Check all refrigeration tubing to assure that it does

not rub against any other parts.

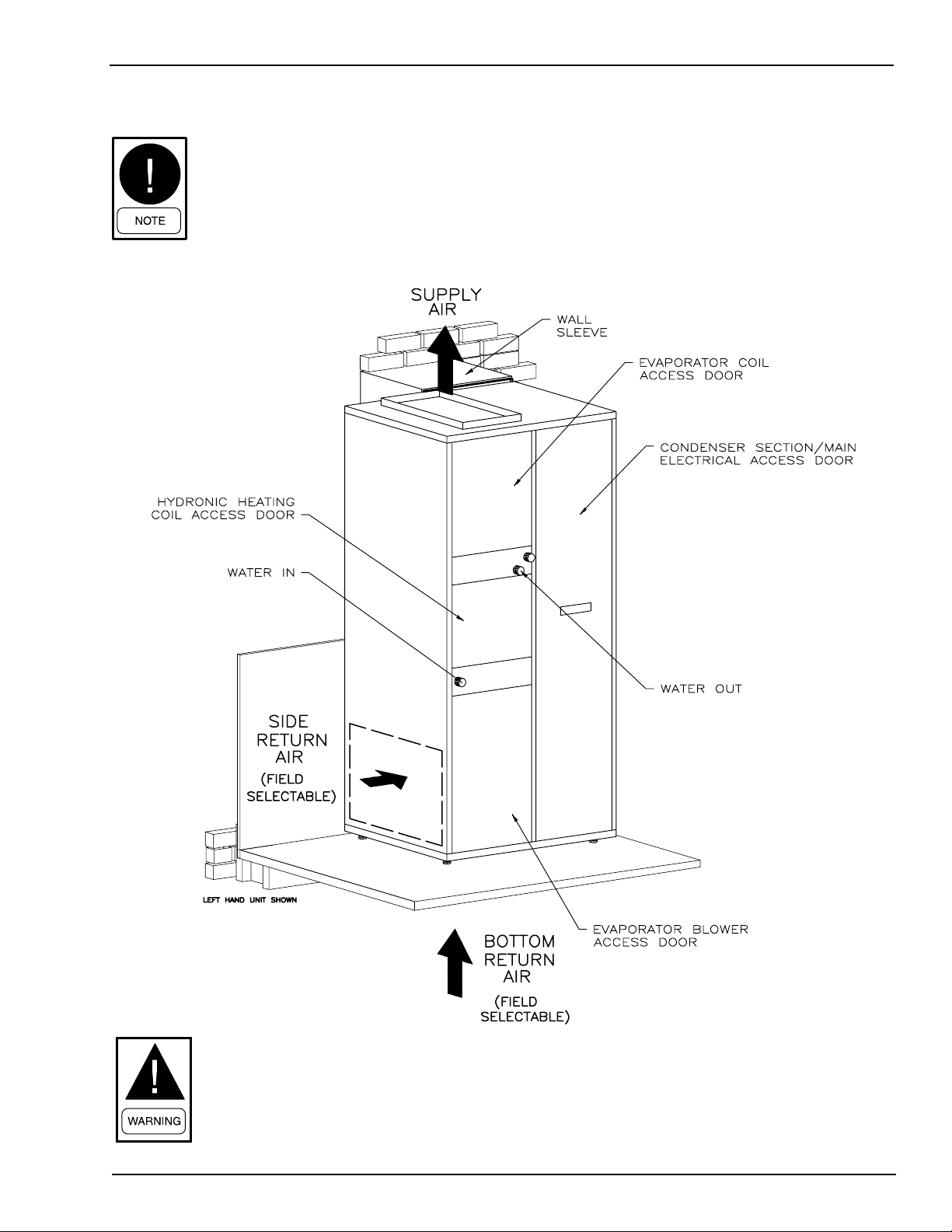

5. NORMAL INSTALLATION

This unit is designed for indoor installation adjacent

to an outside wall having an opening for condenser

air-ow. The air ow products must:

A. Discharge directly to the outside.

B. Discharge away from any obstructions, which

could cause recirculation of the hot condenser

exhaust.

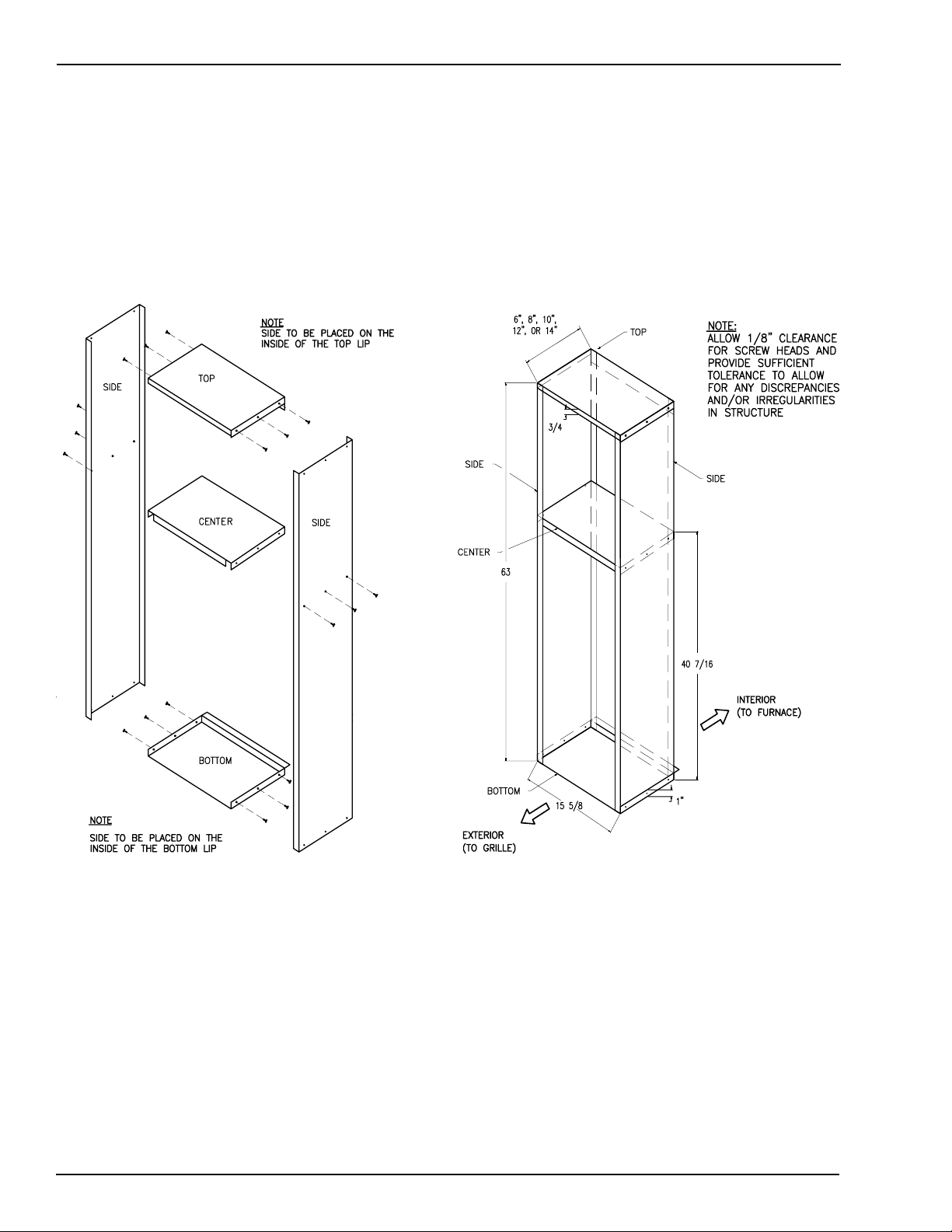

6. CLEARANCES

This unit is designed for closet installation. No

clearance is required from the top, sides, or back

of the unit. A minimum of 1-inch clearance is re-

quired from the front to any combustible materials.

A combustible door may be placed 1 inch from the

front of the unit. When the door is open there must

be 30 inches clearance to any obstruction, to allow

sufcient access for service and the replacement

of parts. The unit shall not be installed directly on

carpeting, tile or other combustible material other

than wood ooring.