C-START

Document Number: CST1001 i

Document Name: C-Start Installation Manual

Table of Contents

1Site Planning and Preparation ......................................................................................................1

1.1 Positioning the C-Start...........................................................................................................2

1.2 Electrical ................................................................................................................................3

1.2.1 Power Requirements....................................................................................................................3

1.2.2 Conduit Requirements .................................................................................................................3

1.2.3 Wiring Requirements....................................................................................................................4

2Installation.......................................................................................................................................5

2.1 Installation Hardware.............................................................................................................5

2.2 Recommended Tools.............................................................................................................5

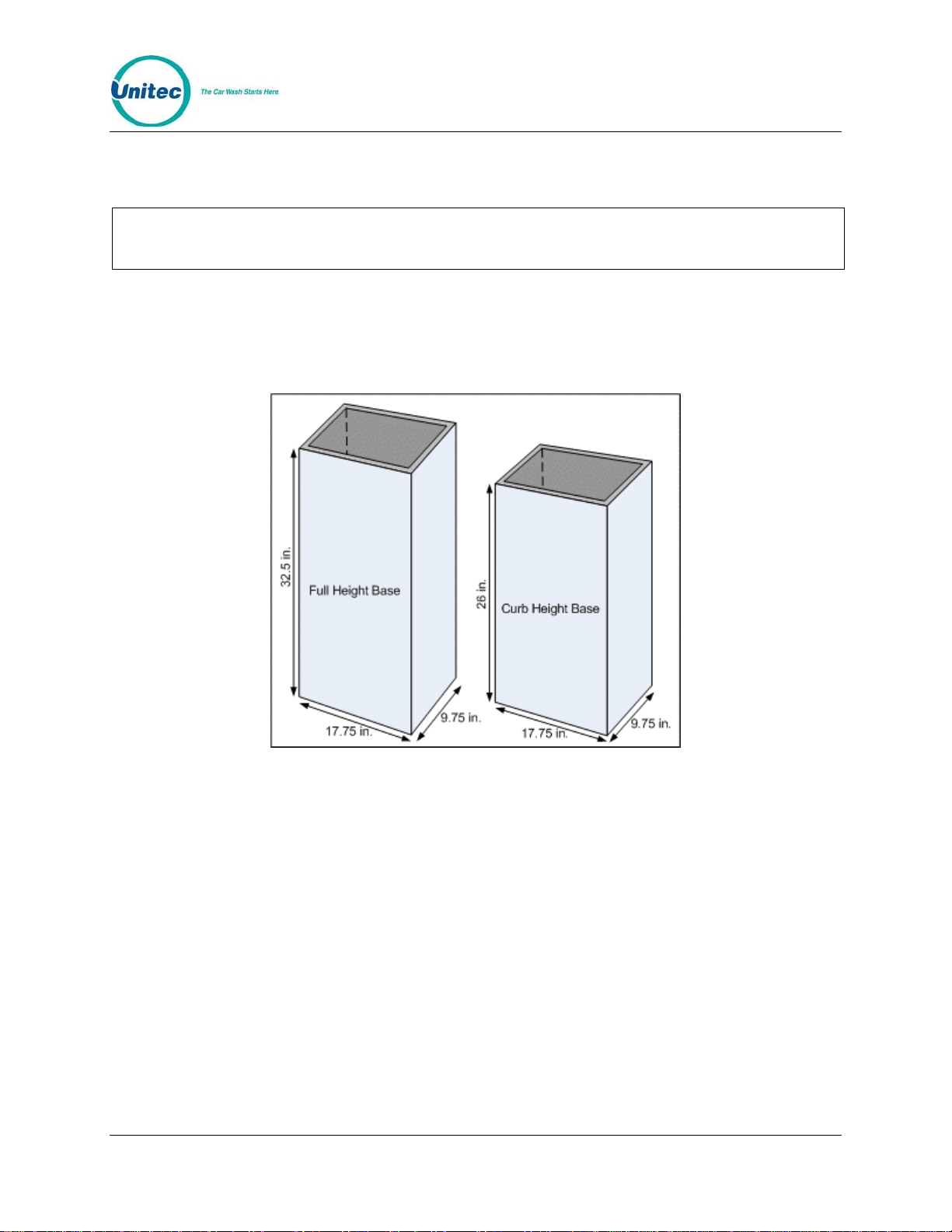

2.3 Base Installation ....................................................................................................................6

2.4 Mounting the C-Start..............................................................................................................7

3Electrical Connections...................................................................................................................7

3.1 General..................................................................................................................................7

3.2 Connecting Power .................................................................................................................8

3.3 Wash Control Wiring..............................................................................................................9

3.3.1 Overview......................................................................................................................................9

3.3.2 Wiring the Wash Relay Interface................................................................................................10

3.3.3 Wiring the Wash-In-Use Interface..............................................................................................10

3.4 Network Cable Connection..................................................................................................11

3.5 Intercom Systems................................................................................................................11

3.5.1 Overview....................................................................................................................................11

3.5.2 Intercom Connections................................................................................................................12

3.5.3 Intercom Adjustments ................................................................................................................12

3.5.4 Connection Overview.................................................................................................................12

4System Startup .............................................................................................................................13

5System Test...................................................................................................................................13

Appendix A - POS Interface Option...................................................................................................15

Appendix B - C-Start Networking ......................................................................................................16

Appendix C – Terminating Ethernet Cables.....................................................................................18