Subject to change without notice. 5PHH50–150G3

REV — 6/15/20

INSPECTION

Upon receiving the unit, inspect for structural,

interior, and exterior damage that may have

occurred during transit. Report any damage to the

carrier and le a damage claim immediately.

MOUNTING

The unit is a self-contained horizontal heating

system. It should be mounted on a at level

surface. The units may be double stacked for

shipping and storage.

NEVER FORK LIFT OR CRANE LIFT DOUBLE

STACKED UNITS. ALWAYS FORKLIFT OR

CRANE A SINGLE UNIT AT A TIME.

INSTALLATION

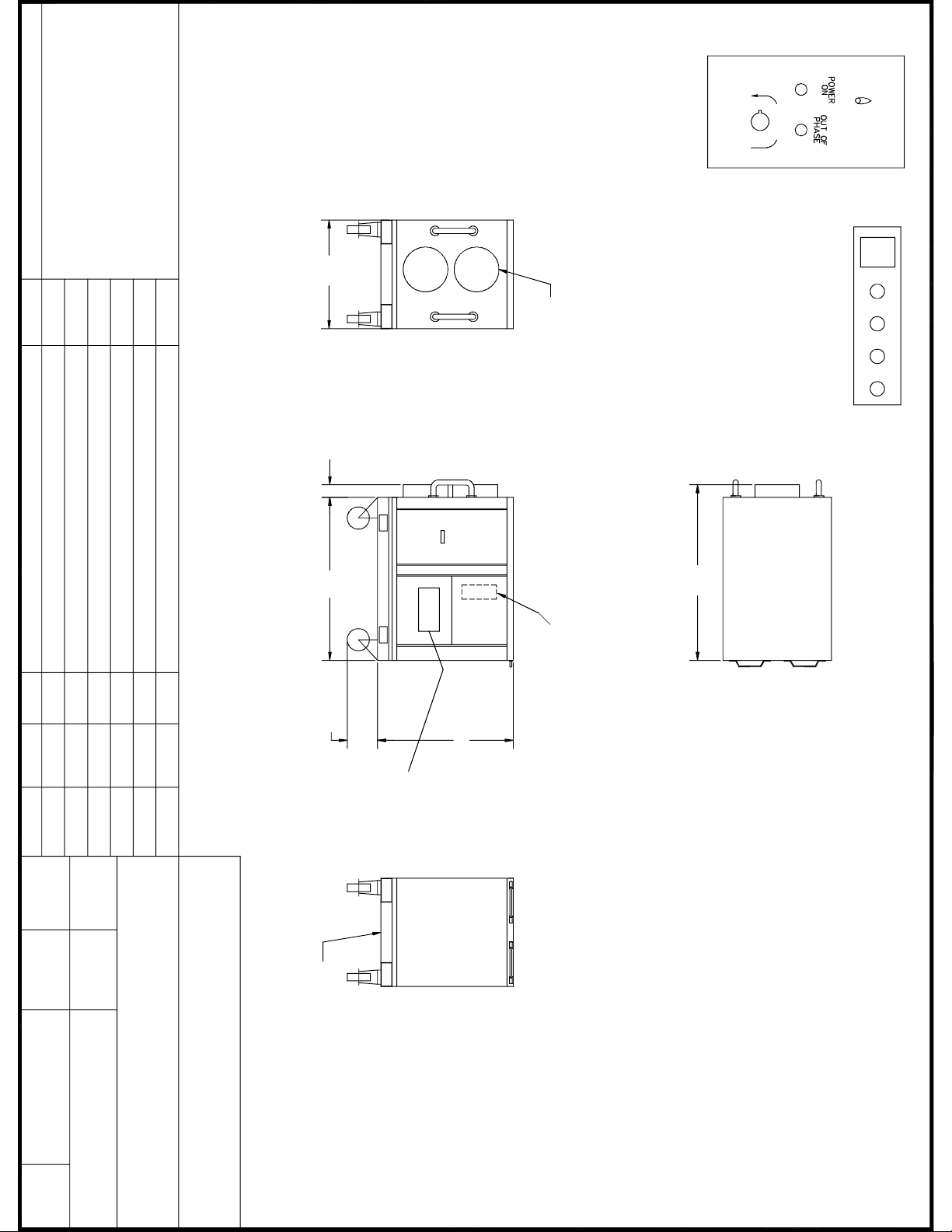

The standard conguration of the horizontal

heating units are shown in Figure 1. The unit will

be shipped as a single packaged unit.

Figure 2 – Horizontal Heater

1. Move the unit to the location of operation

using the forklift pockets located in the base

of the unit. DO NOT STACK the Heaters. Use

spreader bars when using a crane to lift the

heater.

2. Power must be supplied to the unit from a

power source (commercial or generator)

via connecting power wires or cables which

terminate in a Camlock tting. Check the main

power source being utilized to ensure it has

the capability to deliver the required power to

the unit.

3. Route power cables with Color Coded quick-

connect Camlock Plugs to the unit from the

main power supply. Attach the power cables

to the color coded Camlock receptacles. Refer

to Figure 3 – Camlock Receptacles / Circuit

Breaker / Data Label for location. Make sure

the power supplied to the unit matches the

power requirements for this unit. Refer to

the Electrical Data Label provided on the unit

or the specications section of this manual

for power requirements. The Color Coded

Camlock input connectors have spring loaded

metal covers. Simply pull back the cover, push

the Camlock plug into the Camlock receptacle

and twist ¼ turn until the connector locks.

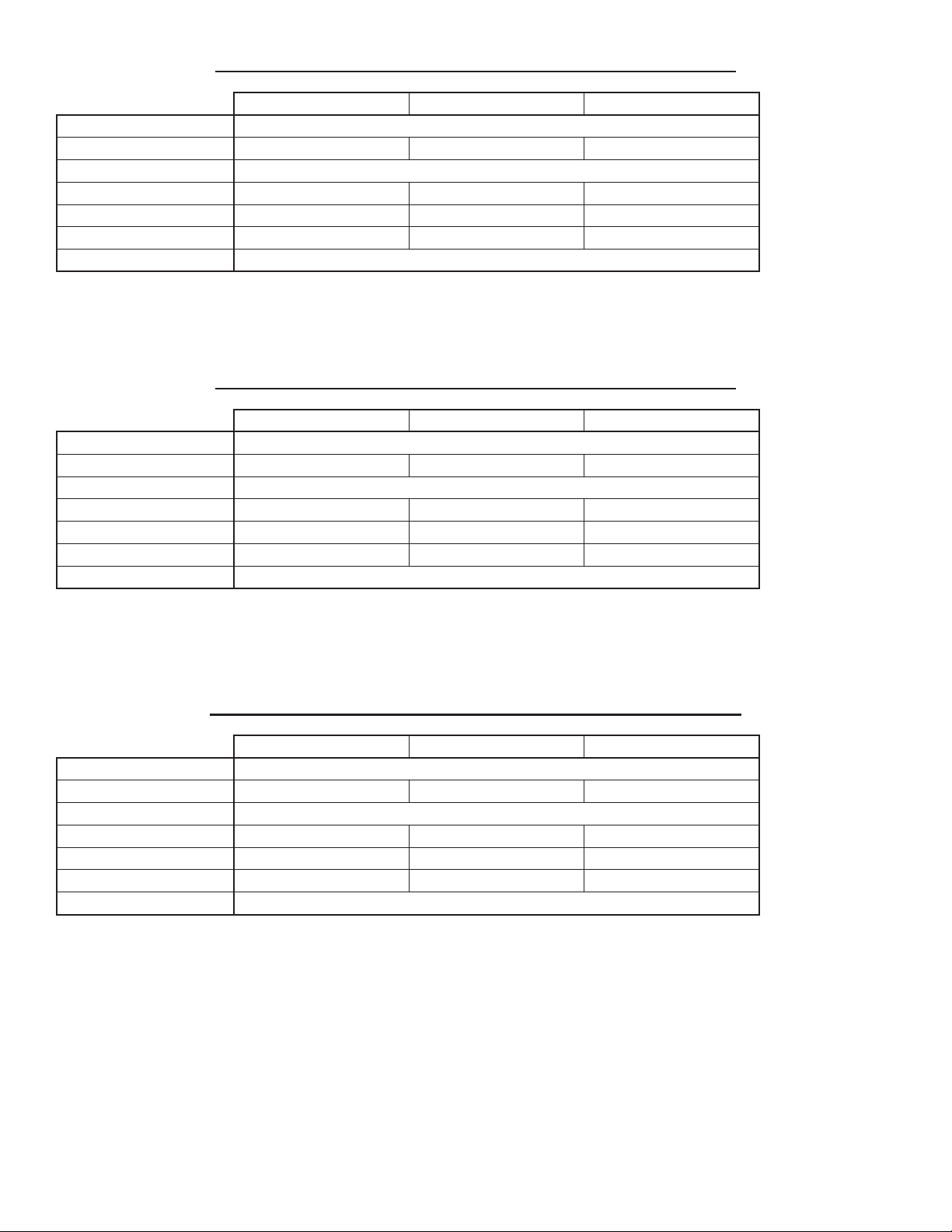

Figure 2 – Camlock Receptacles /

Circuit Breaker / Data Label

4. The unit has a circuit breaker to disconnect

power at the unit up to the point of the unit’s

circuit breaker. Refer to Figure 3 above for

location. Make sure the unit’s circuit breaker

is in the OFF position before applying power

to the unit.

CAUTION: WHEN POWER IS ON AT THE MAIN

POWER SOURCE AND THE UNIT’S CIRCUIT

BREAKER IS OFF, BE CAREFUL BECAUSE

Camlock Receptacles

Data Label

Circuit

Breaker