5

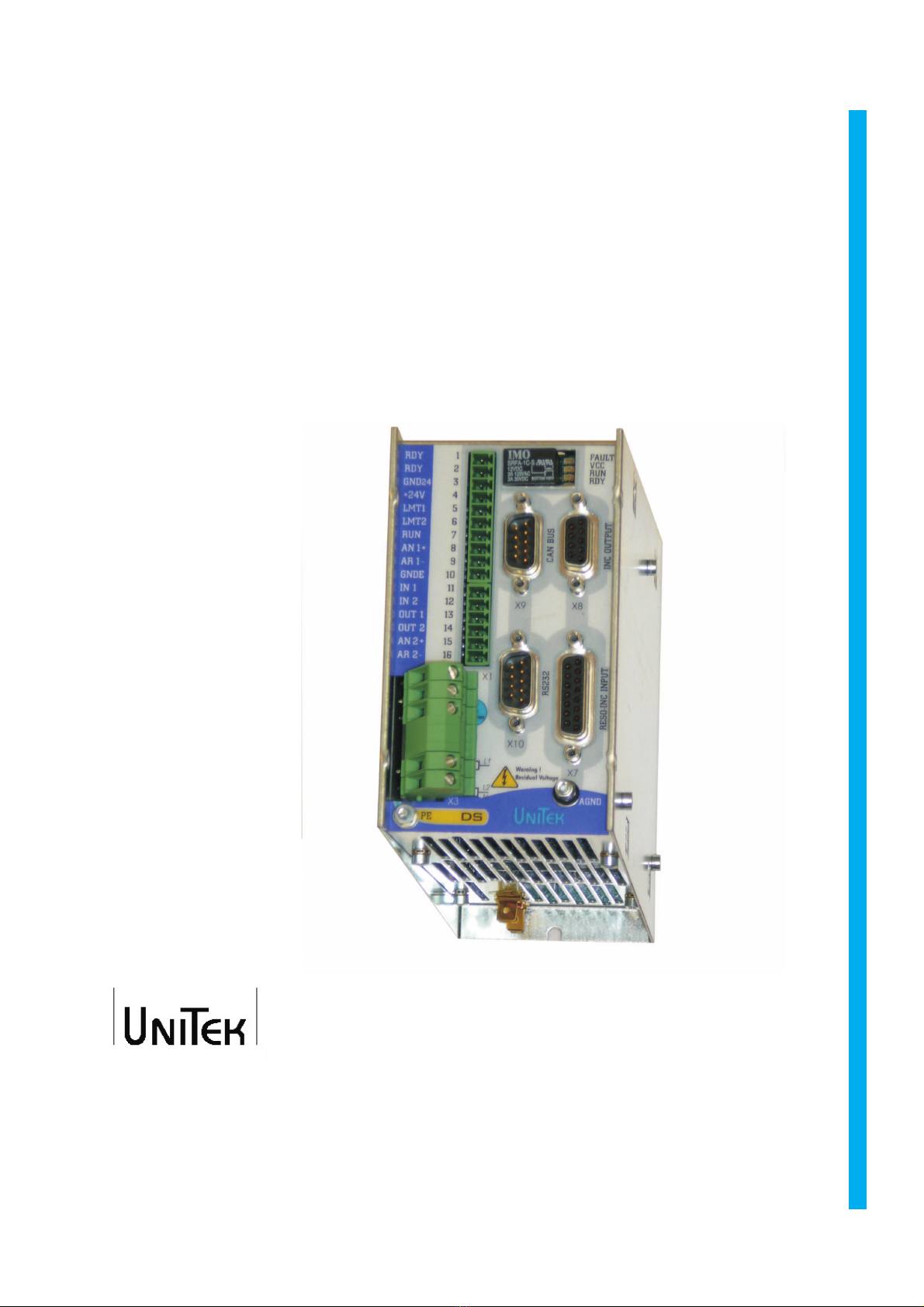

DS 2420, DS 4820

General information

The digital 3-phase current servo amplifier DS xx in combination with the brushless dc

motor (synchro servo motor, CE motor) provide a drive solution free of maintenance and

with a wide dynamic control range. The drive displays the well-known good control

characteristics of dc drives without the disadvantages of the carbon brushes’ wear and the

commutation limits. The rotor moment of inertia is notably lower and the threshold power is

greater than with equally constructed dc motors. This results in up to 5 times higher

acceleration values. Compared to asynchronous motors with frequency converters the

stability, the control range and the efficiency of the drive are considerably improved. The

generated heat in the motor only occurs in the stator, therefore, the EC motors always have

the protection rating IP 65.

From the electrical view, the brushless dc motor is a synchro motor with a permanent

magnet rotor and a three-phase current stator.

The physical characteristics correspond to those of dc motors, i.e., the current is

proportional to the torque and the voltage is proportional to the speed. The speed is

steadily controlled up to the current limit (max. torque. In case of an overload the speed

drops and the current remains constant.

The speed/torque characteristic is rectangular.

Current, speed, and position are precisely measured. The field frequency is not

controllable, it is automatically adjusted.

The motor voltages and the motor currents are sinusoidal. A maximum motor efficiency is

achieved by means of a compensating current control.

The DS 2420 drives can be used as single-axis position amplifier or torque or speed

amplifier.

The position and speed actual value is generated in the encoder unit (resolver or

incremental encoder). The encoder pulses are emitted from the amplifier for a

superordinate PLC/CNC control. The control circuits of current, speed, and position are PID

controllers which are easy to program. They can be programmed by means of a PC or a

programming box. The communication with superordinate controls is effected by means of

BUS systems (standard CAN-BUS, RS232) or by analogue interfaces.

Note:

The energy is fed back into the battery during brake operation.

No ballast (regen) circuit.

For any operation via a mains supply circuit (without battery) a separate ballast circuit or a

voltage watchdog must be installed.

Information:

Digital servo-amplifiers > UNITEK series DS200, DS400

Analog three-phase servo-amplifiers > UNITEK series TVD3, TVD6, AS

Analog dc servo-amplifiers > UNITEK series TV3, TV6, TVQ6

Thyristor current converters 1Q, 4Q, servo > UNITEK series

Classic

, 200W to 800kW

DC and ac servo-amplifiers for battery operation > UNITEK series BAMO A2, A3, D3

analog and digital series BAMOBIL

General information