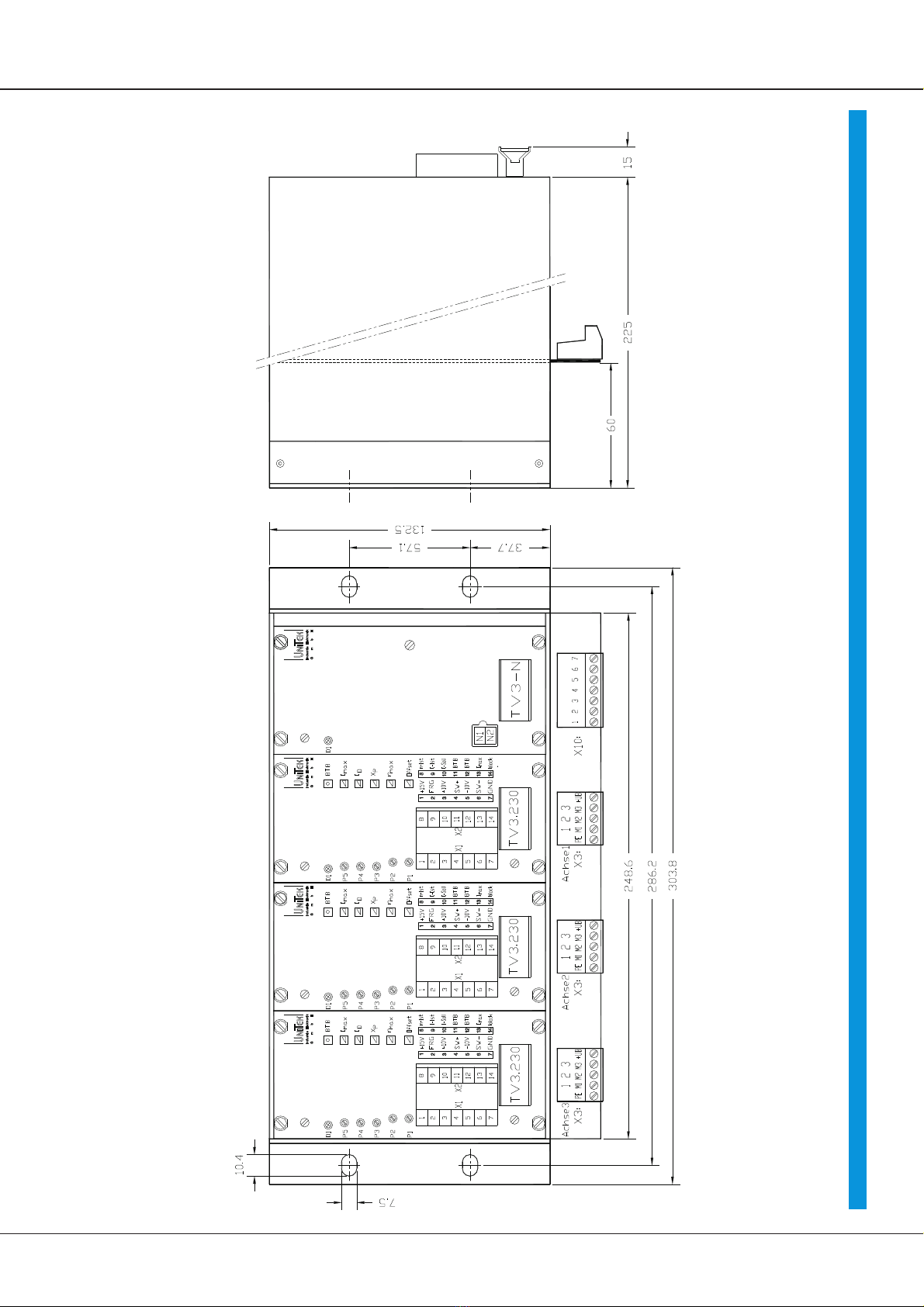

Transistor-Servo-Drive TV3.230

4

General Information

The transistor servo amplifier SERVO-TV3.2 forms together with the direct current

servomotor a propulsion unit distinguished by its high regulating quality

The physical characteristics correspond to those of the direct current motors, that is, the

current is proportional to the torque and the voltage is proportional to the speed. Current

and speed can be measured precisely,

The tachometer actual value is generated from the sensor unit.

(incremental encoder with rotor position track or resolver.)

The analogue regulation circuits of the servo amplifier are designed simply.

In the speed controller (P-I-controller) of the servo-amplifier the nominal value and the

actual value are processed. The result is the current nominal value.

As occurs in all DC-servo-amplifiers which are supplied by the dc-bus ,

the feed-back of the energy must be observed when braking in the dc-bus (especially

where stroke or eccentric cycles are concerned). The ballast circuit is designed for 3%

on-period, higher cyclic durations can be reached by adding external resistors. (option)

Information:

Further servo-amplifiers for DC-servo-motors

for low power SERVO -DC TV3&TV6 24 ... 120V, 6 ... 12A

for midrange power SERVO -DC TVQ6 up to 250V, 10 ... 25A

for high power Classic Q2, Q6 up to 250V, 15 ..60A

Motor governor for DC-shunt motors

from midrange upto

higher power Classic Q1, Q3 up to 550V, 15 ... 2000A

3-Phase-servo-amplifier analog for AC-synchro-servo motors

for low power SERVO -AC TVD3-2 24 ... 115V, 5 ...10A

SERVO-AC TVD3-230 230V, 5...10A

for midrange power SERVO - AC TVD6-2 200V , 400V, 5 ... 25/40A

for high power SERVO-AC AS250/275, AS450/475

3-Phase-servo-amplifier digital for AC-synchro-servo motors

for low power upto

higher power Digital-AC-SERVO DS 2xx 230V, 5...10A

Digital-AC-SERVO DS 4xx 400V, 5...50A

Battery Drive BAMO C 24V, 10...40A

BAMO A1,A2,A3 24..200V, 10...500A

BAMO D3 (digital) 24..200V, 10...500A

General Information