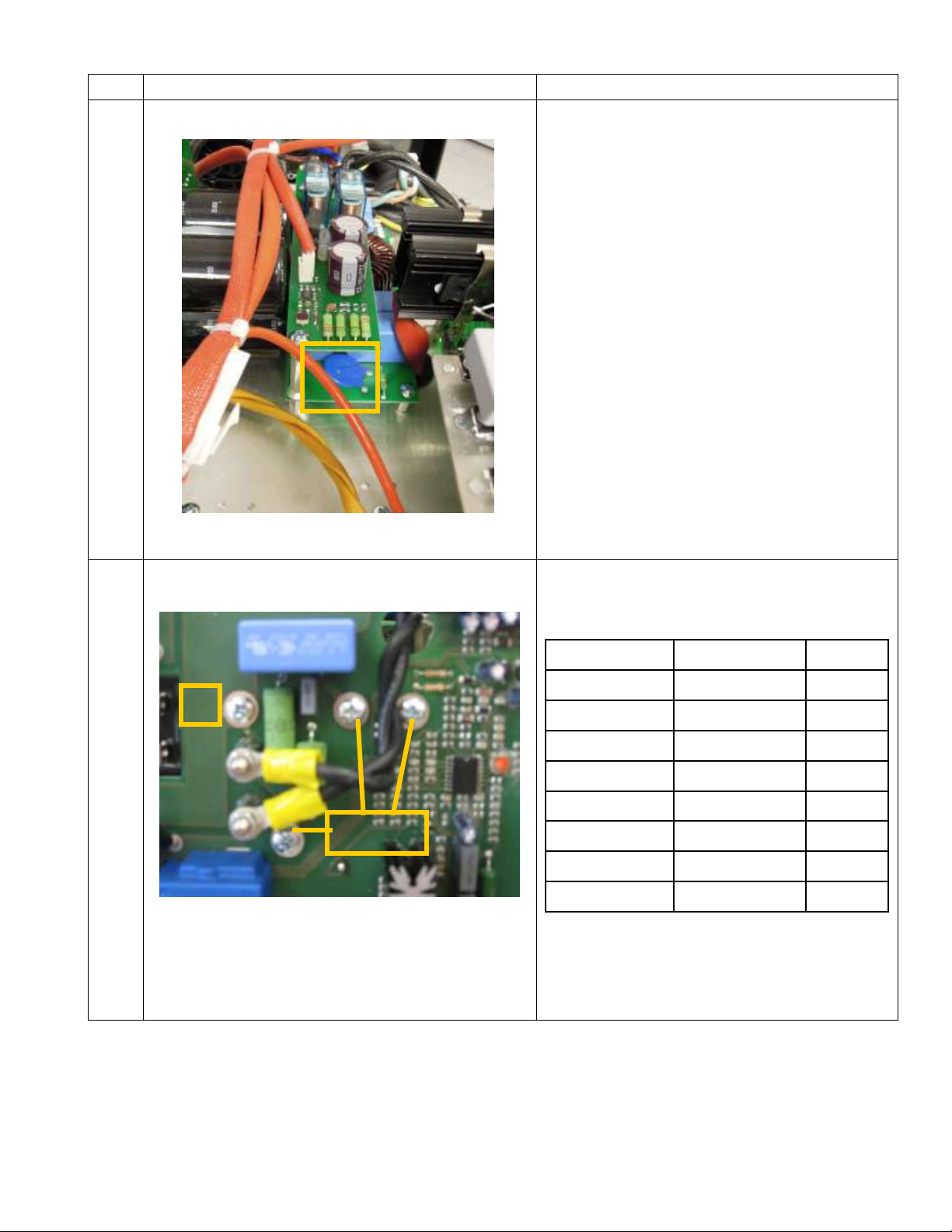

Yellow led on.

Output voltage in each

procedure is about

13.5V. Thermal

protection device

enabled.

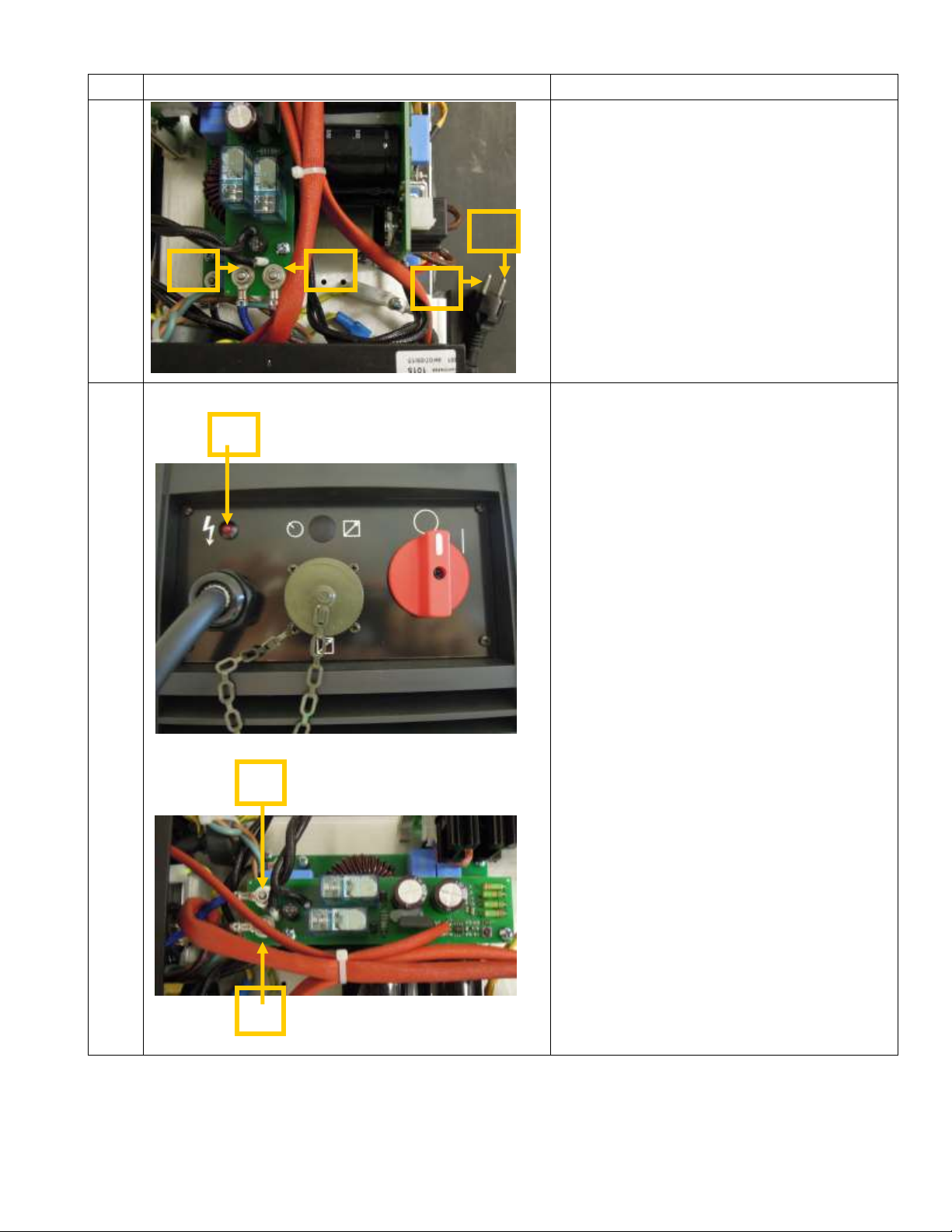

Yellow led onThermal protection

device keeps onUsing a

continuity tester verify

if::Protectors are openProtectors

are closedNone of the above

mentioned cases

Leave the machine on for few minutes to allow

the cooling of the inverter. Switch the

machine off and disconnect the plug.

Remove the hood and make sure:the

temperature of the heat sink tool is less than

40°C;If it is less than 40°C, check if the

thermal protection connectors are closed.

(Picture 7)They are defective, replace

themCheck that the wires are properly

connected to the weld lead connectors

(Picture 7).Erratic feeding in the power board

0070, replace it.

When welding the

protection devices of

the line set off.

Make sure the welding current does

not require greater power than the

one supplied by the line.

Decrease the welding current.

The remote control is

damaged.

Check that the 4-pin connector

( picture 13) is correctly inserted

on the front panel.The Front

Panel could be damaged.

Insert the wires into the connectors correctly and

insert the connectors into their housings. Should

this not be sufficient, replace the front panel

board 0015

(Picture 12,13)

The machine always

welds at maximum

current.

The Front Panel 0015 is

damaged.The Power Board 0070

is damaged.The Hall Effect is

damaged or the cable is

disconnected.

Switch off the machine and disconnect the

plug:The Front Panel 0015 must be

replaced.The Power Board 0070 must be

replaced.Connect the cable in the right way,

or if damaged, the Hall Effect must be

replaced.

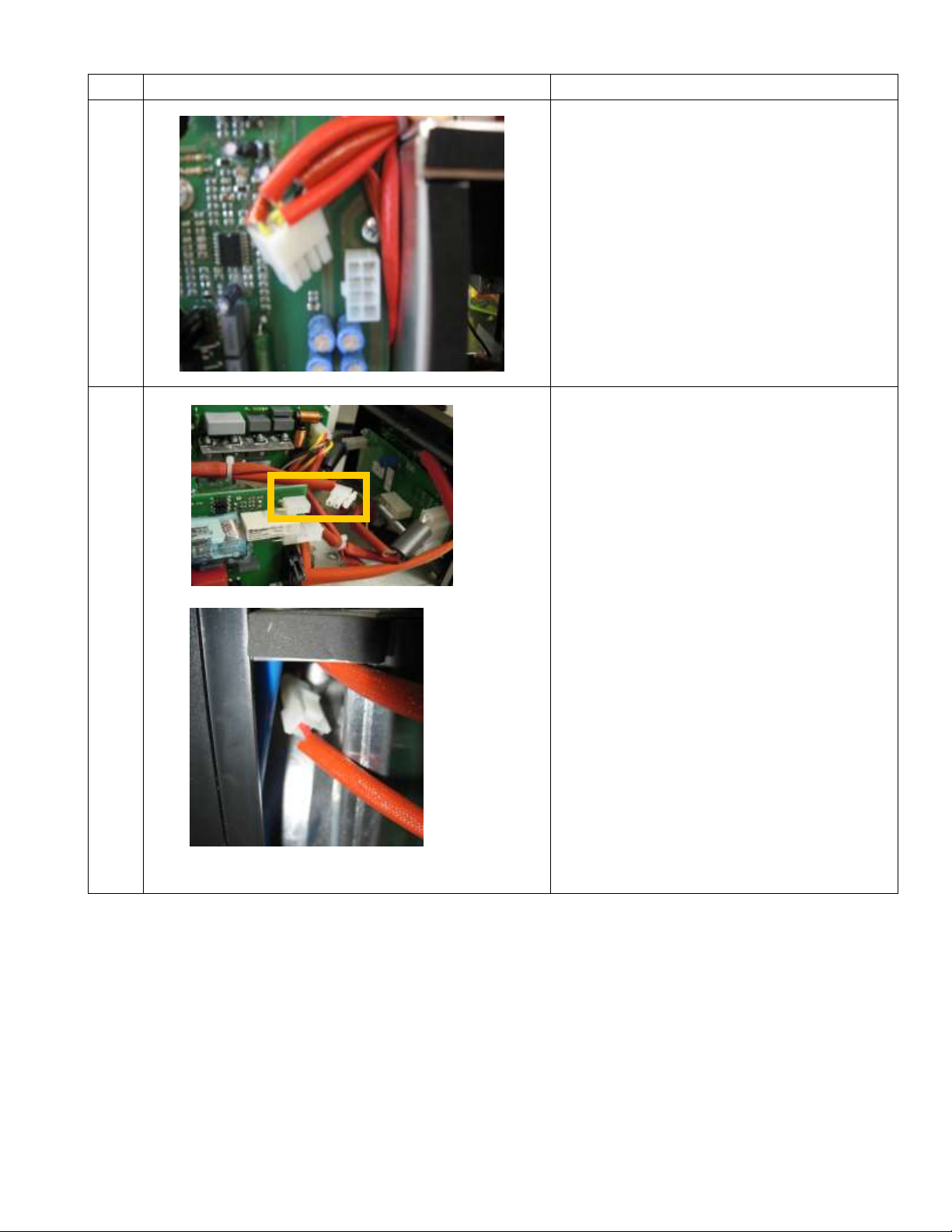

The output voltage in

MMA/TIG is zero and

the welding procedure

is blocked in MMA.

ISOTOP diodes are in short circuit.

The Inversion Module is damaged..

Board 0065 transils damaged

TF POT inductive value is null

Wires Vout damaged

Turn off the machine and remove PCB 0065

(check the ISOTOP diodes):

Replace them (Picture 10)

Replace Module and Board 0071;

Replace Board 0065;

Replace TF POT if damaged.

Checking the wires (Picture 9)