UNITRAY Safe Tray System IDesign & Installation Guide V2 NZ IOctober 2017

2

www.unitray.co.nz

TABLE OF CONTENTS

1 PURPOSE OF DOCUMENT 2

1.1 General 2

1.2 Supporting information 2

2. GENERAL 2

2.1 UNITRAY Safe Tray System explained 2

2.2 UNITRAY Safe Tray System scope of use 3

2.3 Designer & Installer skill level 3

2.4 Health & Safety 3

2.5 Handling & storage 4

3. SPECIFICATION 5

4. INSTALLATION 5

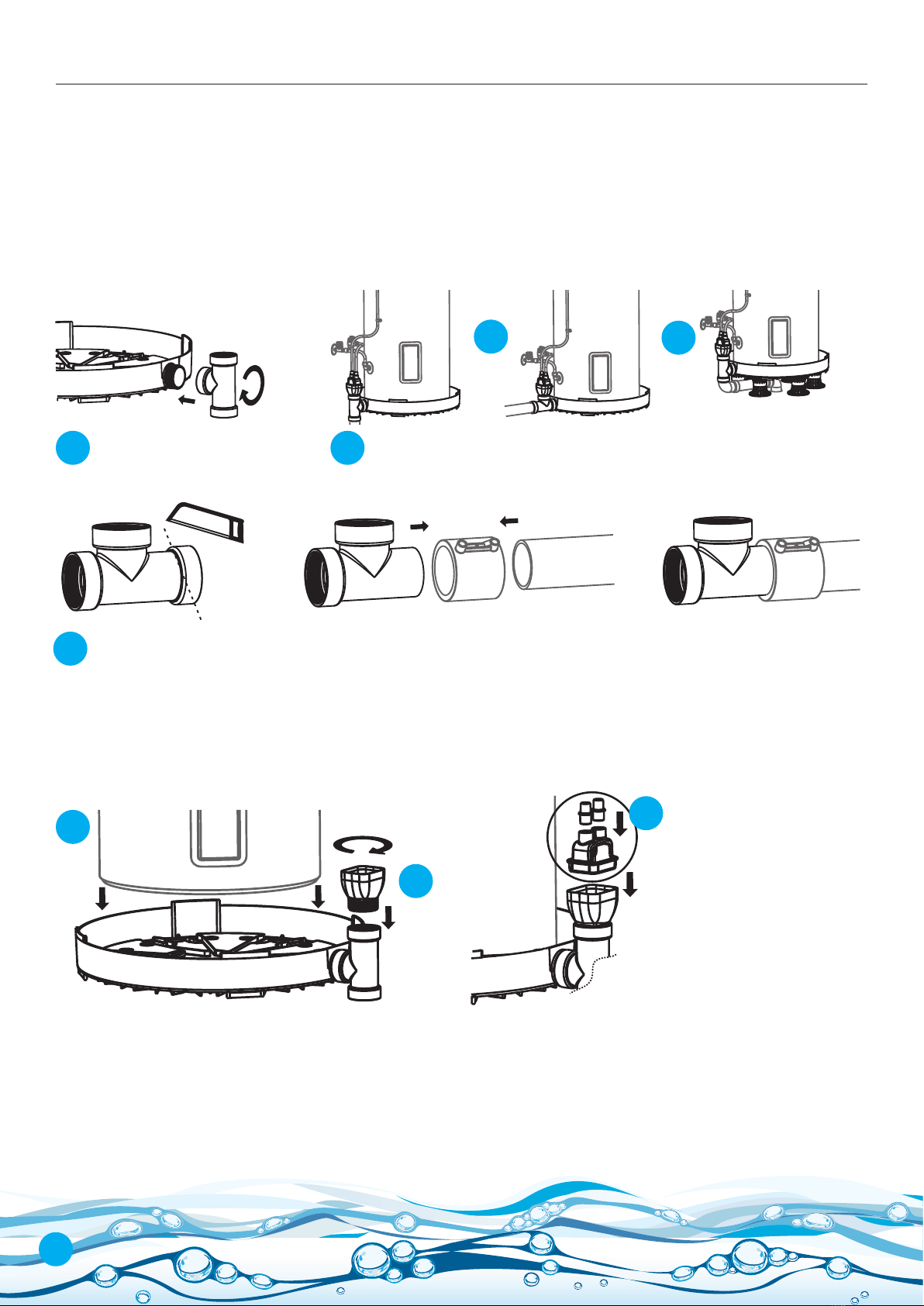

4.1. Assembling the UNITRAY Safe Tray System 5

4.1.1. Inserting the elevating posts into the UNITRAY

Safe Tray System 5

4.1.2 Assembling the T-Connector 5

4.1.3 Assembling the Tundish 7

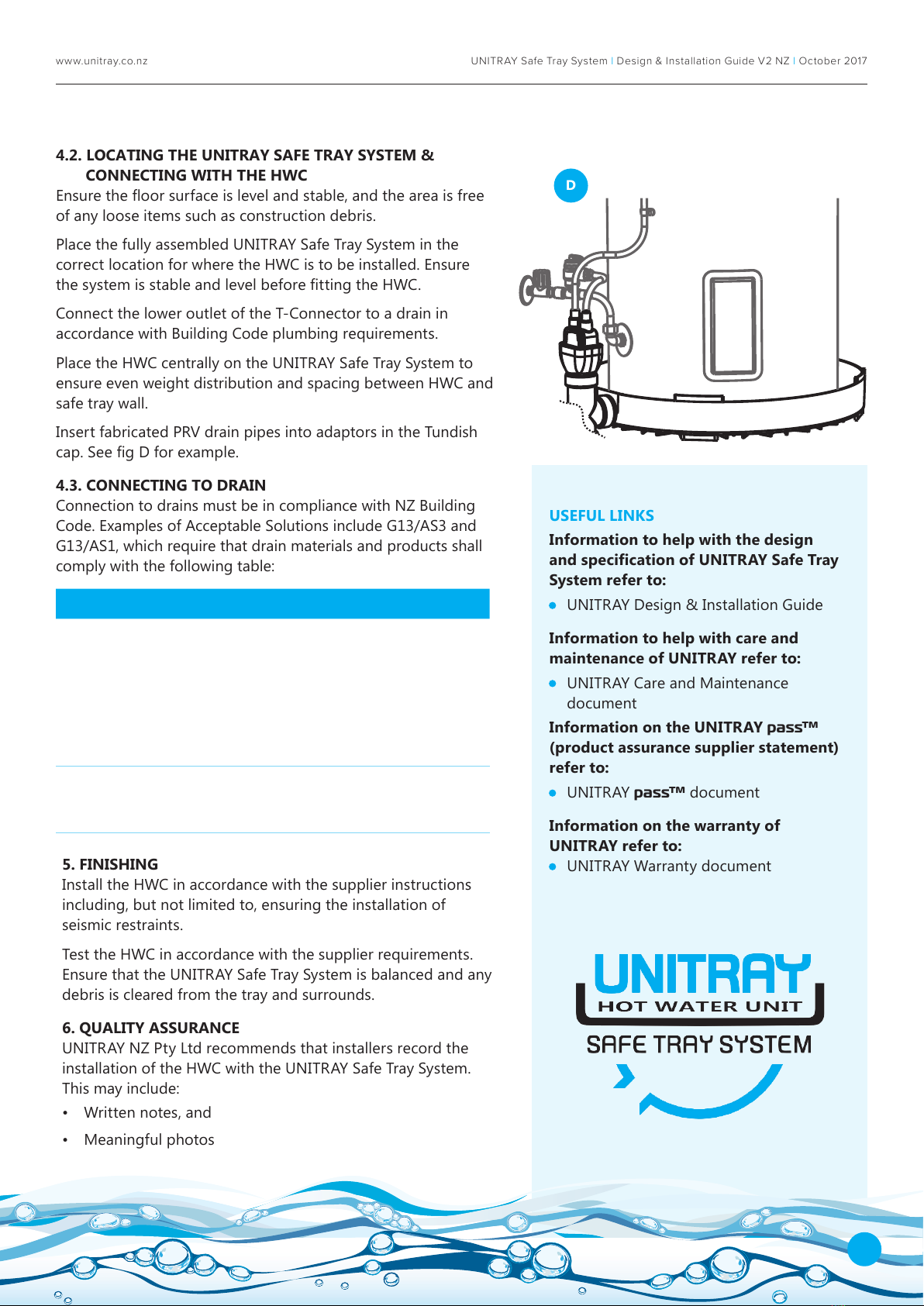

4.2. Locating the UNITRAY Safe Tray System &

connecting with the HWC 7

5. FINISHING 8

6. QUALITY ASSURANCE 8

7. ADDITIONAL RESOURCES 8

1. PURPOSE OF DOCUMENT

1.1. GENERAL

This document is intended for designers and

installers to ensure that the UNITRAY Safe Tray

System is specied and installed correctly.

1.2. SUPPORTING INFORMATION

This document must be read in conjunction

with the following documents:

•UNITRAY Safe Tray System pass™

(product assurance supplier statement)

•UNITRAY Safe Tray System Care and

Maintenance

•UNITRAY Safe Tray System Warranty

•UNITRAY Installation Sheet

2. GENERAL

2.1. UNITRAY SAFE TRAY SYSTEM

EXPLAINED

The UNITRAY Safe Tray System comprises

•UNITRAY Safe Tray

•Tundish components

•T-Connector

•Elevating posts (optional)

The UNITRAY Safe Tray System is designed

specically for use with hot water cylinders

(HWC) that utilise a controlled heat source. It

is designed to collect and drain any accidental

overow, thereby protecting the building and/

or neighbouring properties from damage or loss

of amenity.

It may be installed internally or externally

depending on the position of the HWC.

The UNITRAY Safe Tray System is made

from light weight, high density polyethylene

Qenos (HDPE 0390) complying with BS EN

1778: 2000. It is available in 3 sizes:

•482 mm diameter (internal) Small

•590 mm diameter (internal) Medium

•695 mm diameter (internal) Large

The Tundish is supplied in 3 easily assembled

parts plus adaptors to suit the relief drain

diameter (15 mm or 20 mm). The Tundish

assembly ensures the relief drain discharges

with a regulated air gap.

For more information on Unitray NZ Pty Ltd

please contact:

+ 64 21 365 130

www.unitray.co.nz

Uncontrolled in printed format