TABLE OF COTETS

NOTICE ...........................................................................................................................1

INTRODUCTION............................................................................................................2

SECTION 1 - SAFETY ...................................................................................................3

1.1 SAFETY SUMMARY................................................................................3

1.2 SAFETY LABELS......................................................................................

1.2.1 EXAMPLES OF SAFETY LABELS ..........................................

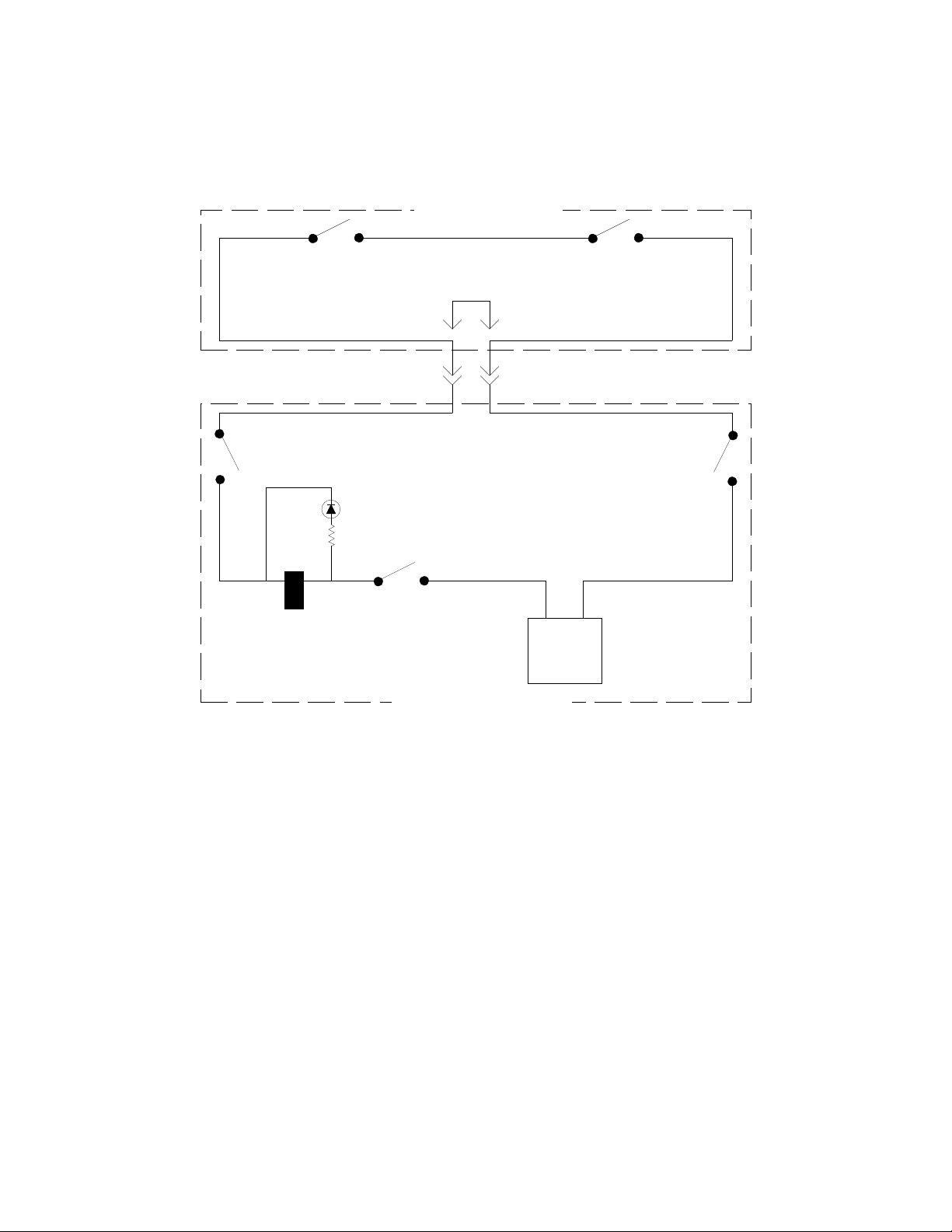

1.3 SAFETY INTERLOCK ..............................................................................5

1. ELECTRICAL SAFETY ............................................................................5

SECTION 2 - INSTALLATION......................................................................................7

2.1 CAUTIONS ................................................................................................7

2.2 SET UP PROCEDURE ..............................................................................7

2.2.1 VENTILATION PROCEDURES ................................................8

2.2.2 CONNECTION WITH COMPUTERS .......................................9

2.2.3 DIP SWITCH LOCATION..........................................................9

2.2. RS-232 SERIAL CABLE CONFIGURATION...........................10

SECTION 3 - OPERATION............................................................................................11

3.1 BASIC OPERATING PROCEDURE ........................................................11

3.2 TURNING THE LASER SYSTEM ON.....................................................11

3.2.1 EMERGENCY OFF SWITCH ....................................................11

3.3 CONTROL PANEL LAYOUT...................................................................12

3. OPERATION CONTROLS........................................................................13

3.5 SHUTTER CONTROLS ............................................................................15

3.6 PROCESSING SPEED CONTROLS.........................................................15

3.7 LASER CONTROLS..................................................................................17

3.8 SOFTWARE CONTROLLED POWER CHANGE (optional) ..................20

3.9 FOCUSING PROCEDURE........................................................................20

3.10 COMMAND SYSTEM ..............................................................................22

3.11 VIEW POSITION INDICATOR ................................................................22

3.12 LASER PROCESSING AREA...................................................................22

SECTION - MAINTENANCE .....................................................................................2

.1 SAFETY SUMMARY................................................................................2

.2 GENERAL CLEANING.............................................................................25

.3 OPTICS CLEANING..................................................................................26