Recoilless Needle Scaler

UT9912

Description

The Universal Tool model UT9912 Recoilless Needle Scaler features a patented vibration dampening system. The low

vibration and high blow frequency results in less operator fatigue and increased production. This versatile tool is used on

flat and irregular surfaces for removing weld flux, paint, rust, scale and to resurface concrete.

PL-2079 FPMC

Read Operating Instructions

Always become familiar with all the instruc-

tions and warnings before operating any

pneumatic tool.

Always Wear Approved Eye Protection

Impact resistant eye protection should meet

or exceed the standards as set forth in the

United States ANSI Z87.1, Occupational and

Educational Eye and Face Protection. Look

for the marking Z87.1 on your eye protection

to insure that it is an approved style. For

further information, ANSI Z87.1, Occupa-

tional and Educational Eye and Face

Protection, is available from the American

National Standards Institute, Inc., 11 West

42nd Street, New York, NY 10036.

Hearing Protection is Recommended

Hearing protection should be used when the

noise level exposure equals or exceeds an 8

hour time-weighted average sound level of

85dBA. Process noise, reflective surfaces,

other tools being operated nearby, all add to

the noise level present in your work area. If

you are unable to determine your noise level

exposure, we recommend the use of hearing

protection.

Avoid Prolonged Exposure

to Vibration

Pneumatic tools can vibrate during use.

Prolonged exposure to vibration or very

repetitive hand and arm movements, can

cause injury. Stop using any tool if discom-

fort, tingling feeling or pain occurs. You

should consult your physician before

resuming use of the tool.

90 PSIG Maximum

This tool is designed to operate at an air

pressure of 90 pounds per square inch

gauge pressure (90 PSIG) maximum, at the

tool. Use of higher air pressure can, and may

cause injury. Also, the use of higher air

pressure places the internal components

under loads and stresses they were not

designed for, causing premature tool failure.

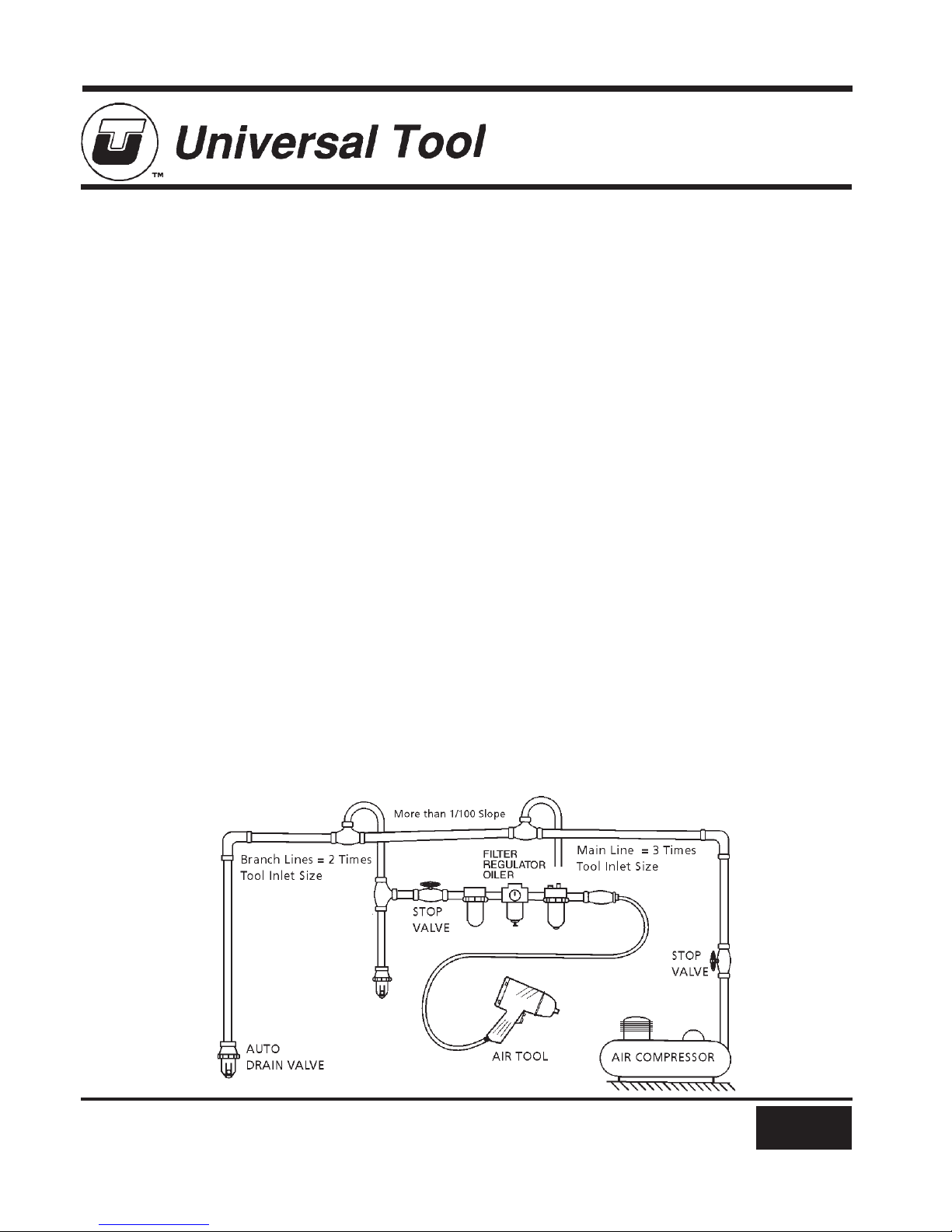

The air supply should be clean and dry,

preferably lubricated. For best results, drain

the moisture from your compressor daily.

PLEASE READ AND FOLLOW ALL WARNINGS

Specifications

Number of needles ....................................................... 18

Needle size ......................................................... Ù" X 7"

Blows per minute ..................................................... 9000

Stroke length ............................................................... ¼"

Vibration level ....................................................... 3 m/s2

Overall length .......................................................... 12¼"

Weight ................................................................. 4¼ lbs.

Air inlet ............................................................... ¼" NPT

Hose size ............................................................. Ú" I.D.

Average air consumption ....................................... 3 CFM

Maximum operating pressure ................................ 90 PSI

Universal Tool

A Division of Florida Pneumatic Manufacturing Corporation

851 Jupiter Park Lane, Jupiter, Florida 33458

Toll Free 1-800-327-9403

WARNING: SOME DUST CREATED BY POWER SANDING, SAWING,

GRINDING, DRILLING, AND OTHER CONSTRUCTION ACTIVITIES

CONTAINS CHEMICALS KNOWN TO CAUSE CANCER, BIRTH

DEFECTS OR REPRODUCTIVE HARM. SOME EXAMPLES OF THESE

CHEMICALS ARE:

LEAD FROM LEAD-BASED PAINTS

CRYSTALLINE SILICA FROM BRICKS, CEMENT AND OTHER

MASONRY PRODUCTS

ARSENIC AND CHROMIUM FROM CHEMICALLY TREATED LUMBER

YOUR RISK FROM THESE EXPOSURES VARIES, DEPENDING ON

HOW OFTEN YOU DO THIS TYPE OF WORK. TO REDUCE YOUR

EXPOSURE TO THESE CHEMICALS, WORK IN AWELL VENTILATED

AREA AND WORK WITH APPROVED SAFETY EQUIPMENT SUCH AS

THOSE DUST MASKS THAT ARE SPECIALLYDESIGNED TO FILTER

OUT MICROSCOPIC PARTICLES.