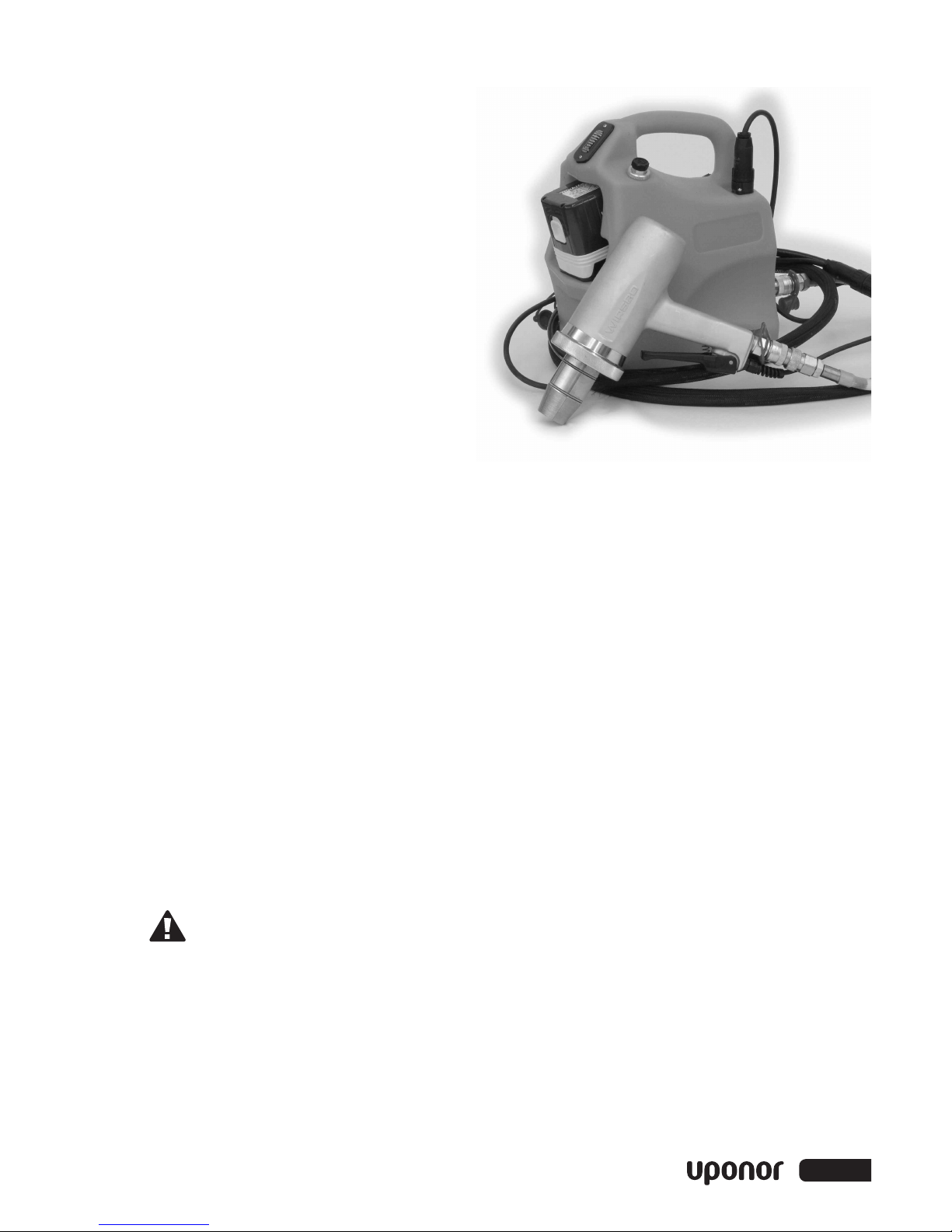

Section 3 – Battery Operation

Charging the Battery

Only use the charger provided in the tool kit to charge the battery for the

ProPEX 200 Battery Expander Tool. Charge the battery before initial operation.

1. Remove the charger from the case.

2. Plug the charger into a standard outlet.

3. Ensure the vent slots in the top and bottom of the charger are

not obstructed.

4. Insert the battery into the charger (+ pole to + pole) with

minimum force.

5. A flashing red light on the battery charger indicates the battery

is charging.

6. Recharge time takes about one hour (the red indicator light on the

charger stops flashing and remains on when the charge is complete).

Note: Battery temperature increases during and shortly after use. Batteries may

not accept a full charge if they are charged immediately after use. Allow the

batterypack to cool to room temperature before charging.

Caution: Do not use the charger at ambient temperatures of less than

50°F (10°C) or greater than 104°F (40°C).

Battery Handling

The ProPEX 200 Battery Expander Tool uses rechargeable batteries containing

nickel metal hydride (NiMH) cells. To effectively and properly use the batteries,

keep the following in mind.

• Recharge cool batteries only.

• The battery can recharge 1,000 times, and reaches full capacity after

several charges.

•Store batteries at temperatures greater than 50°F (10°C), but less

than 104°F (40°C), to optimize battery life.

•Only recharge the battery after it is completely drained of power.

•Do not use the charger if dropped or damaged.

• Do not connect two chargers together.

• Keep the battery in a frost-free, dry place.

• Do not allow metal objects (e.g., screws, cutlery, nails) to come in

contact with the battery contacts.

• Use only the provided charger to charge the batteries.

Using any other charger will void the warranty.

• Use only the batteries provided. Using any other battery will

void the warranty.

3